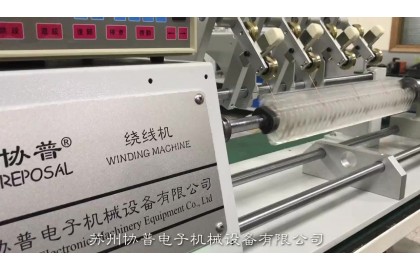

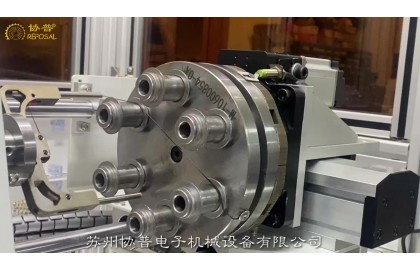

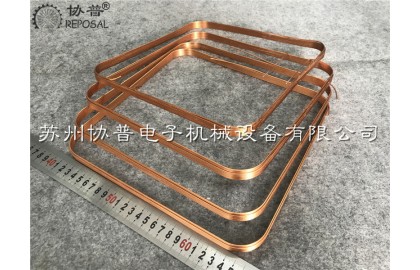

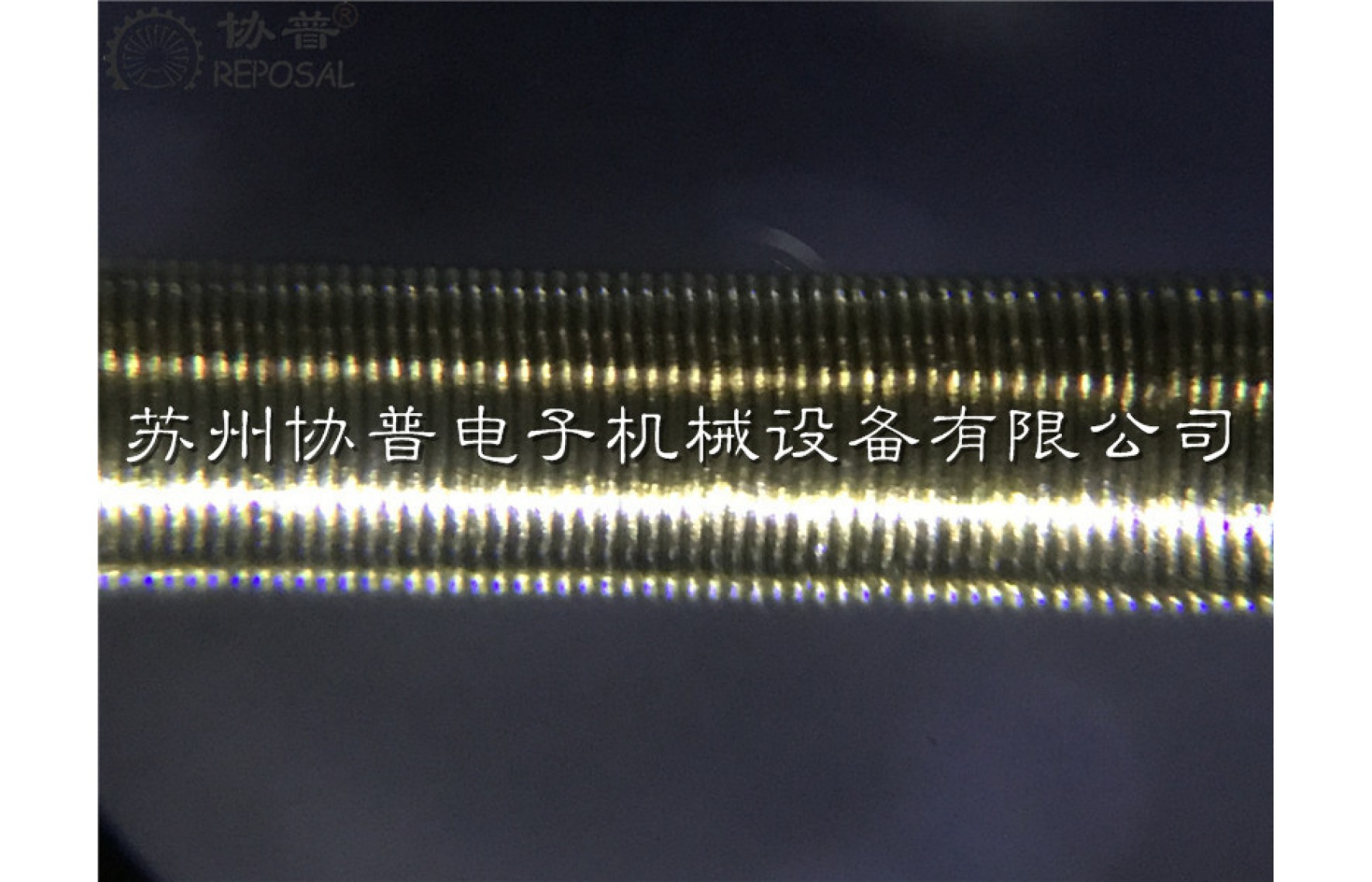

REPOSAL ® winding machine has successfully realized the coil preparation process of the frameless capillary magnetic liquid acceleration sensor

In particular, the non-magnetic material in the magnetic liquid will be subjected to a magnetic field force in the non-uniform magnetic field, which makes many magnetic liquid acceleration sensors can be designed based on this characteristic.

These characteristics make the magnetic liquid acceleration sensor has many advantages compared with the traditional acceleration sensor, such as no wear, high sensitivity and simple structure.

However, most of the existing magnetic liquid acceleration sensors use solid mass blocks as non-magnetic substances, and use coils to detect changes in inductance under different accelerations to obtain output signals. However, its disadvantage is that it leads to complex magnetic circuit and poor sensor stability.

A new solution emerged -- the capillary magnetic liquid acceleration sensor, good stability, simple magnetic circuit, accurate and reliable measurement results and long service life.

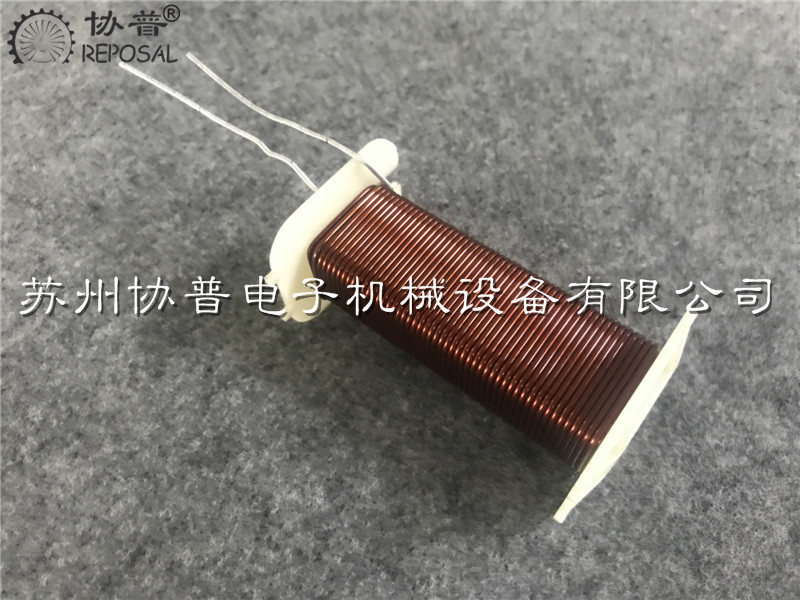

A column of air or non-magnetic liquid insoluble with magnetic liquid is arranged between the magnetic liquid columns at both ends of the capillary. When there is no external acceleration signal, the column of air or non-magnetic liquid will not move. The magnetic liquid columns at both ends of the air column or non-magnetic liquid column in the capillary are symmetrically distributed. When the external acceleration signal, the column of air or non-magnetic liquid moves in the capillary, causing the length of the magnetic liquid column located at both ends of the column of air or non-magnetic liquid to change. At this time, the inductance value measured by the two coils around the capillary changes, so that the acceleration signal can be measured.

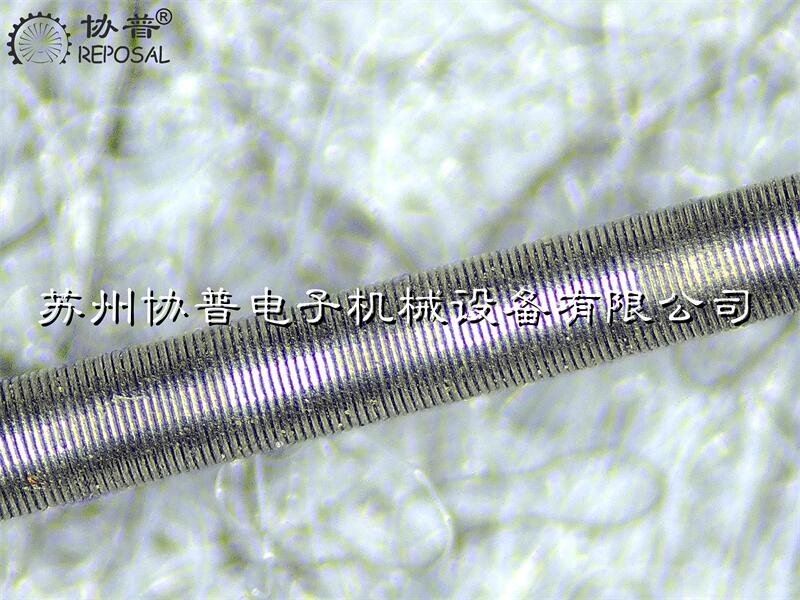

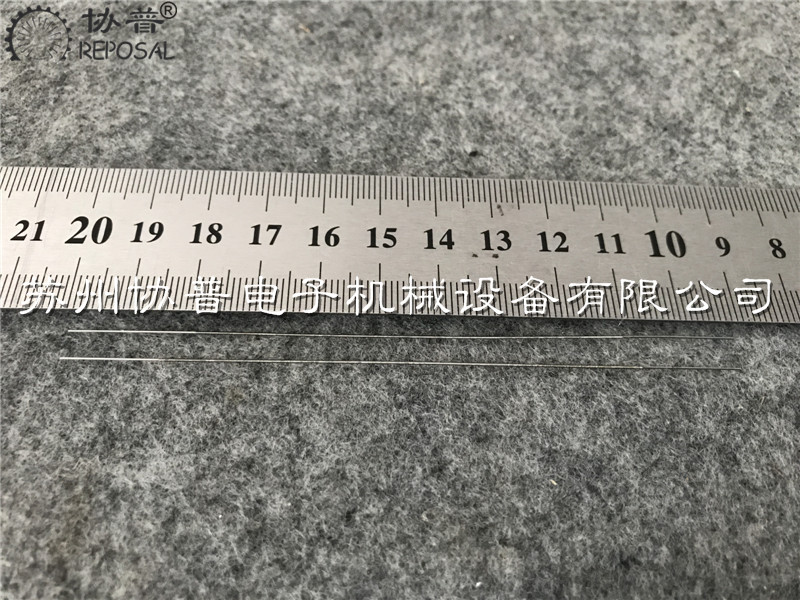

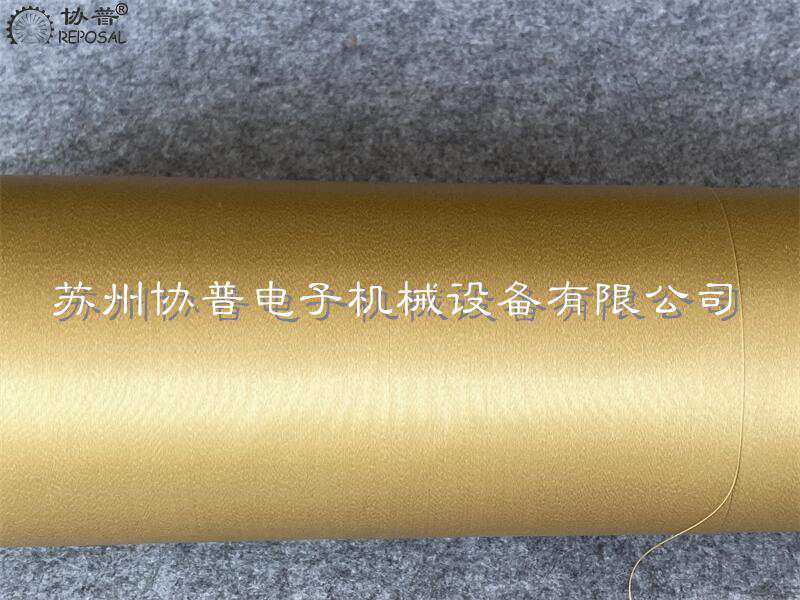

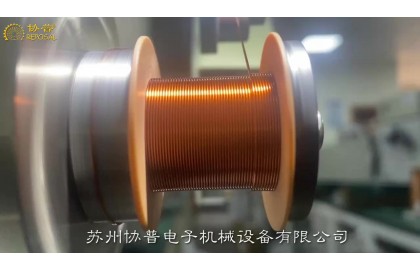

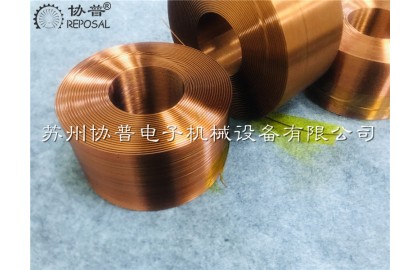

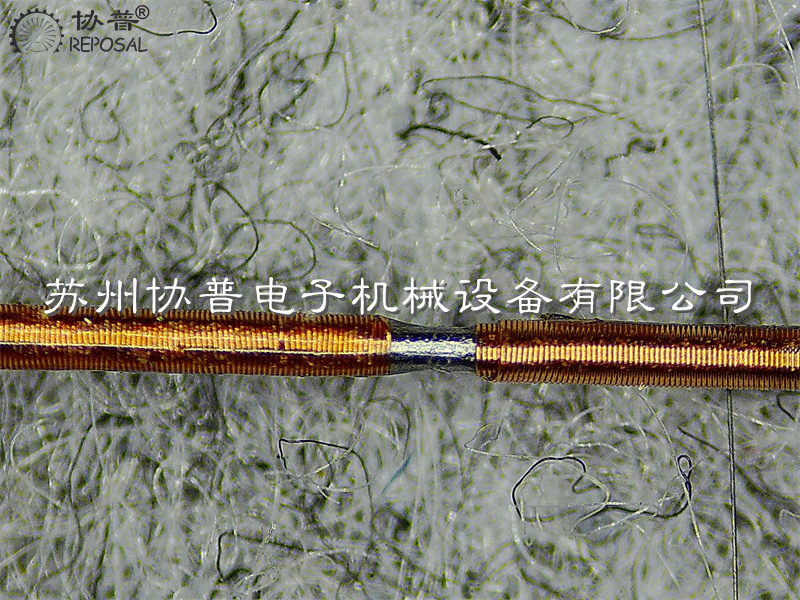

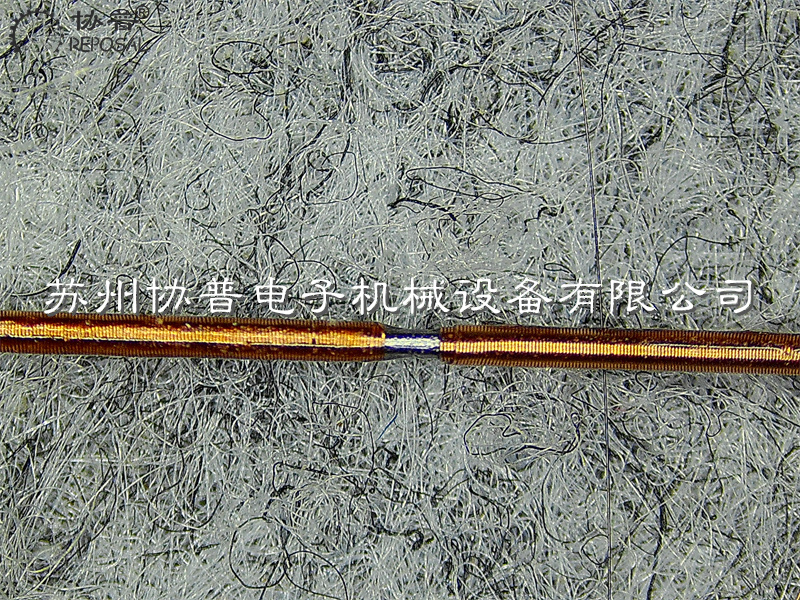

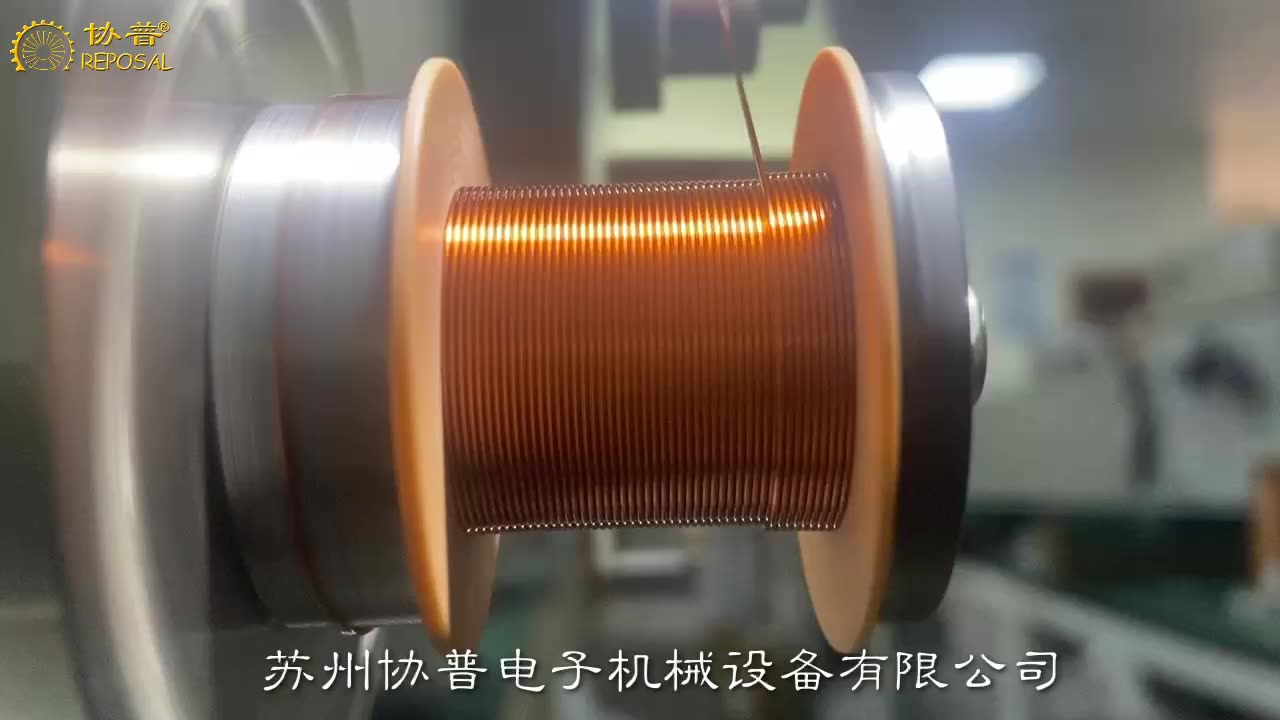

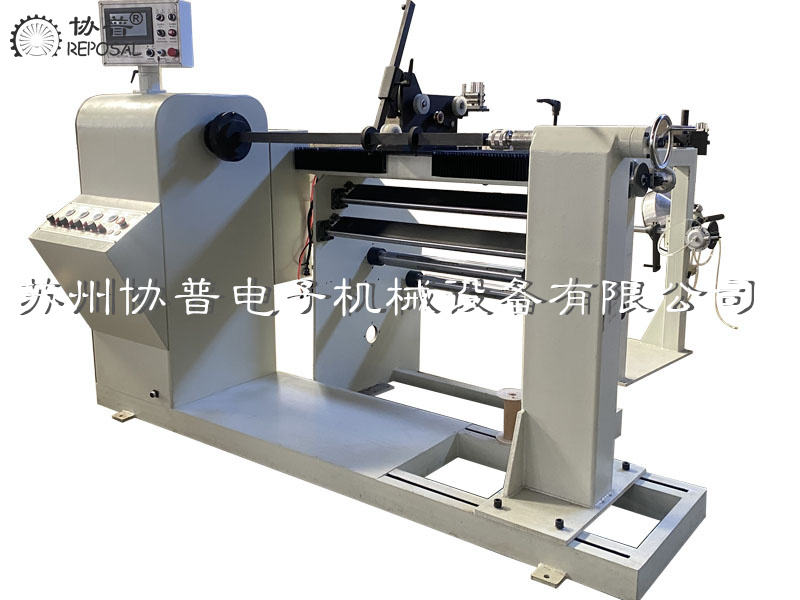

It can be known from the above that the inductor coil set outside the capillary is particularly important, which needs to be stable, sensitive and consistent. However, the capillary diameter is small and the surface is smooth, so the coil is difficult to prepare. Therefore, the current coil winding method is to first wind the coil on a skeleton, and then put the skeleton on the capillary. Under the condition that the same winding has the same wire diameter, the larger the air gap between the coil and the magnetic liquid, the lower the permeability and the smaller the inductance. As a professional winding solution provider, we believe that the ideal solution is to directly wind coils on the capillary tube and arrange them neatly. For this reason, our technicians have finally realized the coil preparation process of the frameless capillary magnetic liquid acceleration sensor after a long time of efforts, repeated tests and continuous improvement.

Related Post

REPOSAL ® winding machine Honeycomb coil winding machine

REPOSAL® numerical control honeycomb winding

machine, specially designed for honeycomb inductor coil, honeycomb coil with

its small size, small distribution capacitance, and large inductance in some

special occasions has irreplaceable. All of these excellent properties are due

to the unique structure of the honeycomb coil,

Traditional honeycomb winding machine is to

rely on a set of complex gear system to achieve the function, if you need to

wind different honeycomb coils, need to manufacture and replace different

gears, quite cumbersome and very low efficiency, REPOSAL® CNC honeycomb winding

machine uses high-precision control system, with specific algorithms, high

precision, fast speed, through different Settings can be wound different

widths, different fold points, Different number of turns of honeycomb coil, let

you wind honeycomb coil handy.

The inductance of the honeycomb coil is large,

mainly because of its special structure. After it is wound, from the

appearance, it is like a honeycomb, formed by the regular winding of coils to

form a honeycomb, in this one honeycomb, the magnetic flux of each honeycomb is

interconnected, and the magnetic flux density of these small magnets changes

with the change of time and position, just like the food in a honeycomb. This

distribution of magnetic flux pores makes the inductance of the honeycomb coil

larger, because it has more magnet interaction, thus forming more magnetic

flux, improving the permeability of the current, making the inductance

increase.

At the same time, since the magnetic flux of

each small magnet in the honeycomb coil is interconnected, the inductance can

be increased by increasing the size of the honeycomb. The larger inductance of

the honeycomb coil is due to its shape and the distribution of magnetic flux

pores, rather than due to the increase in resistance.

The insulated wire wrapped around the honeycomb

coil can be a single strand of enameled wire, or can be multiple strands of

enameled wire or silk-covered wire.

People are usually curious about how this kind

of coil is wound out, and the following is a demonstration of the CNC honeycomb

coil winding machine developed by our company.

REPOSAL®successfully releases hot micro flowmeter winding machine

REPOSAL®successfully releases hot micro flowmeter winding machine

----------solve the problem of heat pipe coil winding process

Flowmeter is one of the commonly used instruments in industrial production, the most common such as all kinds of water meters in life, gear water meters, electromagnetic water meters, ultrasonic water meters, etc., according to the different industry applications, chemical, petroleum, pharmaceutical, food and other industries are also widely used, can measure the volume or quality of various fluids through the pipeline in a given time. Easy to measure in each fluid automation control.

However, in medical, aerospace, military and other fields, we may need to measure tiny fluid flows, and in microfluidic processes, micro-thermal flow meters are also necessary, which can measure very small fluid flows, thereby helping researchers control the flow of fluid in microfluidic devices and optimize device performance.

Another example is the flow control of pure oxygen fluid in the ventilator, the flow control of the medical dosage ratio, the flow equivalent is very small, and at the same time, it requires extremely high measurement accuracy, so the thermal micro-flow meter should appear according to demand.

The thermal micro flowmeter is mainly made of the principle of capillary heat compensation. In the thermal micrometer, the fluid passes through a small pipe, and on the outer wall of the pipe, the thermal micrometer winding machine is used to wind a very small electric heating coil, which usually uses a fine platinum resistance wire, with a diameter between 0.02 and 0.05mm. When the fluid flows through the platinum resistance heating coil, the temperature of the fluid increases slightly. At this time, another set of platinum resistance coils wound by the thermal micro-flowmeter winding machine can sense a higher resistance, and the controller converts this resistance value into a flow value.

The diameter of the platinum resistance coil in the micrometer is very small, and the texture is fragile, and it will heat up after being energized. When the fluid passes through the capillary of the flowmeter, the flow will take away the heat of the platinum resistance coil wound by the hot micro-flowmeter winding machine, resulting in a decrease in the temperature of the platinum resistance coil. In order to keep the temperature of the platinum resistance coil stable, the micro flowmeter will provide a certain current according to the measurement needs to maintain the temperature of the hot wire at a constant operating temperature. By measuring the change in current provided to the hot wire, the mass flow rate of the fluid can be obtained.

Thermal micro flowmeter has many advantages, the main advantage is high accuracy, can measure the flow range of small small fluid, the accuracy can usually be within 1%. Moreover, it is small in size and can be easily designed into module units for convenient arrangement. It can also directly output electrical signals, and the communication with the data collector is convenient.

However, its manufacturing difficulty is high, especially the platinum resistance heating coil, the need for hot micro-flowmeter winding machine, in a very small diameter capillary wound diameter 0.02-0.05 platinum wire, the small diameter of the platinum wire itself is more fragile, the capillary also needs to overcome the radial displacement caused by the tension of the platinum wire during the winding process, and requires orderly arrangement. The tension is stable and the resistance is consistent, so the process is extremely difficult, and the current micro-precision winding technology of this hot micro flowmeter winding machine has been supported by sensor companies in Japan, the Netherlands and Germany for a long time.

The domestic precision winding mechanism manufacturing system from low-end to high-end, there are huge challenges, because there are shortcomings in the manufacturing equipment link, not only the problem of individual equipment such as hot micro flow meter winding machine, but the entire precision winding machine industry is lack of independent development conditions, the industry is keen to imitate foreign industry technology for a long time, and the user long-term superstition imported equipment, It is also one of the conditions for domestic winding machine enterprises to lack independent development, so the cost of domestic thermal micro-flow meters has been high.

REPOSAL ® winding machine to overcome guidance fiber wire winding process difficulties

Guidance communication has an excellent application prospect, but the guided fiber wire package needs to be wound long distance without defects, but because the surface of the fiber is smooth, brittle and easy to break, as well as the residual stress generated by the micro bending will make the signal attenuation, so it is more difficult to wind than other fibers, making long distance fast fiber automatic winding without defects has become a major issue. REPOSAL® winding machine, as a professional winding process solution provider, has been developing process research on precision winding of guided fiber wire packages for many years. Good progress has been made and REPOSAL® special winding machine for guidance fiber wire wrap developed by the winding machine can set reliable process instruction information according to process requirements and accurately execute control commands to finally finish the long distance guidance fiber wire wrap without defects. In the whole research project, we focus on solving three problems of guidance fiber optic wire wrapping system: tension control. Winding system, feeder system, and expand as follows.

Study on the control of the speed curve of the coiling machine for precision coiling machine

Your factory is using a traditional winding machine, your wire machine structure is reasonable, high mechanical accuracy, the motor is also used a big brand of motor, but in the winding of precision coils, there will be a high defect rate, you carefully analyze before improving various factors - equipment structure, processing accuracy, tooling accuracy, skeleton accuracy, enamel wire quality, tension control, etc. But it still doesn't solve the problem. But to tell you that it's not just a hardware problem, but an algorithm problem, may surprise you. Because in your opinion, every time the spool is transferred, the spool has a corresponding response, but in fact, you may not have considered that in the winding process of the precision coil, the wire guide pin is connected at both ends of the coil, and the sudden change in speed may cause the coil to cross the line and be raised. These defects can degrade the performance of the coil.

To solve this problem, we propose an acceleration and deceleration method based on 5-segment S-curve. The algorithm uses linear acceleration or deceleration at the end and end of the line motion control to help reduce coil defects. We first verify the feasibility of the algorithm by using ADAMS software. The software simulates the motion of the precision winding coil and obtains the velocity curve and displacement curve during the motion. Later, the experimental results show that the method of adopting S-curve in the alignment speed control can reduce the coil defect by up to 50%. This shows that the 5-section S-curve motion control algorithm is a promising method to improve the precision and efficiency of the winding process of electric precision coils. By using this algorithm, coil manufacturers can reduce the risk of coil defects and improve coil performance.

Winding machine is a special production equipment for precision winding coils. They can be divided into stator winding machine, flying fork winding machine, ring winding machine and flat winding machine according to the working mode and object. Different types of equipment are suitable for the production of different objects. For example, the stator winding machine is mainly used to produce motor stator coils, while the parallel winding machine is used to produce electromagnetic switching coils.

Ordinary algorithm of parallel winding machine in the production of precision winding coil products, although our mechanical structure, parts processing accuracy has been done very well, but often there is a problem of low wiring accuracy. In the process of winding a line coil, there are two main movements, one is the rotating movement of the skeleton, which is called winding movement, and the other is the translation movement of the guide needle, which is called wiring movement, and wiring transport is matched with winding movement. After years of technical accumulation, we analyze that the leading role in the alignment accuracy is the alignment movement of the guide needle. Therefore, if you want to improve the alignment accuracy of the coil, you need to optimize the alignment movement of the guide pin.

In fact, we have always believed that the winding machine is equivalent to the lathe in the electrical industry, its importance is self-evident, so for its accuracy, there have been many experts and scholars to study this.

Some people studied the mathematical model of precise alignment based on axial pressure compensation around the axis in the process of alignment. The axial pressure was used to improve the alignment regularity of the coil, and the mathematical model was established according to the analysis of the end point of the coil alignment, which improved the alignment accuracy of the coil.

Some people use the 5-section S-curve control algorithm and the 7-section S-curve control algorithm respectively in the research. In motion control, the 7-section S-curve is more complicated than the 5-section S-curve control. This method has achieved more results in the field of CNC machining, but it is not mature in the field of winding machine.

The tension instability caused by the friction between the enamelled wire and the conductor nozzle during coil winding has been studied, which leads to the uneven wiring of the coil and the breakage of the enamelled wire.

Some people have studied the low efficiency of the winding machine in the traditional winding control because of the inertia error in the process of the winding machine. Instead, the servo motion wiring and the inertia error supplement are used to improve the control efficiency of the winding machine.

PLC control is commonly used in the winding machine wiring control system, through PLC control servo motor can realize the winding machine wiring control, both PLC control stability and high precision servo motor advantages. However, there is a sudden impact of guide pin speed in the coil alignment of parallel winding machine, so it is necessary to further optimize the change of guide pin running speed to improve product quality and the smoothness of wire alignment speed. The S-curve algorithm is a kind of smooth transition of speed in the process of motion, which is often used in machining to solve the problem of breaking the tool caused by speed impact and improve the precision of machining products. In the winding machine, the speed of the guide needle can be changed into an arc smooth transition by controlling the movement track of the guide needle, improving the alignment accuracy and product quality.

To sum up, an algorithm based on 5-segment S-curve motion control is proposed to solve the problem of velocity shock in the process of coil alignment by analyzing the law of coil alignment. ADAMS software is used to simulate the trajectory of the guide pin to verify the feasibility of the algorithm. And the application of the example proves that the 5-section S-shaped curve can effectively solve the phenomenon of crossing and protruding in the process of winding, and improve the precision of winding.

Coil wiring principle

The winding method is flat winding, that is, the enameled wire moves synchronously with the guide pin and always keeps perpendicular to the skeleton during winding. The frame is driven by the winding motor with the guide needle movement, the enameled wire is wound on the skeleton, in which the guide needle is located in the wiring arrangement mechanism and the winding mechanism are two independent mechanisms. The winding mechanism is divided into three stages according to the motion process of the guide pin, namely acceleration and deceleration stage, uniform speed stage and end point return stage. The acceleration and deceleration stage can be divided into two parts: acceleration stage and deceleration stage. In the early stage of the alignment movement, the guide pin speed from zero to uniform speed belongs to the acceleration stage. At the end of the alignment movement, the process of decelerating until the speed reaches zero is a deceleration stage. The middle constant velocity stage is the constant velocity motion stage of the guiding needle. The terminal reentry stage is a process in which the guide needle accelerates backward again after slowing down and stopping. Here we explain:

Acceleration and deceleration stage

In order to arrange the lines evenly, the two movements of guide pin movement and skeleton rotation should meet certain coordination relations during acceleration and deceleration stage. The time for the guide needle to move one diametral width distance must be equal to the time for the skeleton to rotate once, that is, the guide needle to move just one diametral distance when the skeleton rotates once.

REPOSAL® Winding machine Optimum design of CNC winding machine for large power transformer

In the manufacture of power transformers, winding the transformer coil is a super important step, you think, the transformer coil is wound more firmly and neatly, the strength of the transformer and the ability to protect against short circuits can be greatly improved. However, most of the current transformer winding machines have to rely on manual extra sorting of the coil, the entire equipment is low in automation, and the production efficiency is not high, so the development of an excellent large transformer winding machine is a crucial thing for our company.

We have studied the main shaft technology of transformer winding machine, the relationship between compaction force and winding quality, and the control of compaction force. According to the principle and process flow of transformer winding, we put forward a whole design scheme of large transformer winding machine, including mechanical structure and electrical control. Mechanically, we simplify the complex structure of traditional transformer winders. In terms of electrical control, we ensure the stability of the motor when it starts and stops, and ensure that the winding coil is evenly tightened during the winding process. For the core parts of the transformer winding machine, spindle system and pressing device, we have calculated and selected the types and parameters. With the compaction device, we are able to provide real-time axial and radial compaction forces during the winding process of the transformer winding, which is very effective for improving the tightness of the winding.

The static analysis of the radial compaction device of the winding machine is also carried out by using finite element method, and the structure optimization is carried out according to the analysis results. We find that as the number of layers and turns of the winding increases, the required axial and radial compression forces change accordingly. By analyzing the experimental data, we find that there is a maximum value and a minimum value in the range of quality requirements, and it is the most reasonable choice to make the compression force approximately proportional to the number of layers and the number of turns.

The large transformer winding machine developed by our company has been preliminatively debugged and put into the market. After testing, the performance parameters of this transformer winding machine are in line with the design requirements, and the operation is stable and efficient. It can be wound to make a tight and regular transformer winding coil, and has been fully recognized by the market.

As a power grid equipment, power transformer converts voltage through the electromagnetic induction between the winding coils of the transformer. With the continuous development of the market, higher requirements are put forward for the manufacturing level of transformers, and the market needs more energy-saving and efficient transformers. Therefore, the optimization of the transformer manufacturing process is particularly critical. Quality and performance depend on the process equipment. The technical level of the transformer winding machine directly reflects the manufacturing level of the transformer. Therefore, accelerating the development of transformer winding machine is an important guarantee to improve the performance of transformer.

The winding coil of the transformer is the core component of the transformer and constitutes the electromagnetic induction part of the transformer. It generally includes high voltage winding and low voltage winding, respectively connected to the high voltage grid and low voltage grid. The winding of large power transformers usually adopts concentric winding, that is, the high and low voltage transformer winding coils are centrally set on the core column. The manufacture of transformer winding is the core process of transformer, and its quality plays a crucial role in the performance of transformer, affecting the appearance of transformer size, weight, mechanical properties, insulation and heat resistance and other important indicators.

In the past, the production of transformer winding coils relied on manual, and workers had to wind insulated wires manually to the winding die frame in accordance with the process requirements. Turns calculation also have to rely on manual, this old-fashioned method is inefficient, and because the worker's skills are not strong enough, the quality of the winding coil is poor, the number of turns may be miscalculated or missed, and ultimately lead to the finished winding coil performance can not be guaranteed. Later appeared semi-automatic transformer winding machine, which is driven by the motor to rotate the spindle to wind the transformer winding coil, although it improves the production efficiency, but the wiring work still has to rely on manual, only suitable for flat winding transformer winding coil winding, and winding head winding, welding and other operations must still be completed manually, so the product quality is not stable.

Later, with the emergence of TTL logic gate circuits, in the mid-1970s, with the development of CMOS technology, various types of equipment program control a large number of applications of digital integrated circuits, Western countries and Japan and other industrial powers have emerged CNC winding mechanism manufacturing industry. These CNC transformer winding machines represent the advanced level of winding mechanism manufacturing technology, especially the winding equipment produced in Japan, Italy, the United States and Germany is the leading technology.

Now the transformer winding machine as the core parts of the transformer production equipment, the market demand is very large, and the transformer manufacturing enterprises at home and abroad attach great importance to the development and application of advanced technology of transformer winding machine. Domestic transformer winding machine production enterprises are small, insufficient technical reserves, limited research and development funds, so there is still a big gap compared with foreign advanced products, the market share is low, unable to compete with foreign countries. To solve the key technical problems of transformer winding machine is the key to improve the quality of domestic winding equipment and enhance the market competitiveness. In order to meet the demand of transformer manufacturers for high quality and low price winding equipment, especially large transformer winding machine, on the basis of learning from foreign advanced experience, combined with domestic research results, the development of large transformer winding machine has important significance and practical value.

Precision Winding Machine | Hollow Coil Winding Machine | Whole Column Coil Winding Machine

Precision winding machine

Precision winding machine For general winding machines, including CNC and automatic winding machines, only the set number of turns of enameled wire is required to be wound, and the appearance is roughly flat, but there are some special high-demand occasions , It is required that the arrangement of enameled wires must be neat without a random winding.

This kind of coil has several advantages. First, the consistency of inductance is very high. Second, the enameled wire occupies less space, and the enameled wire can reach the ideal neat arrangement. Third, the energy density is high. Fourth, the high temperature resistance performance is better. , The enameled wires are in line contact, and in the case of random winding, the superimposition between the wires will have a little contact, and it is easy to break down under high temperature and high pressure.

In order to achieve a stable and neat arrangement, in addition to the requirements for enameled wires, compared with general coil winding machines, high requirements are put forward for the electronic control, mechanism design and manufacturing accuracy of structural parts of the fine winding machine.

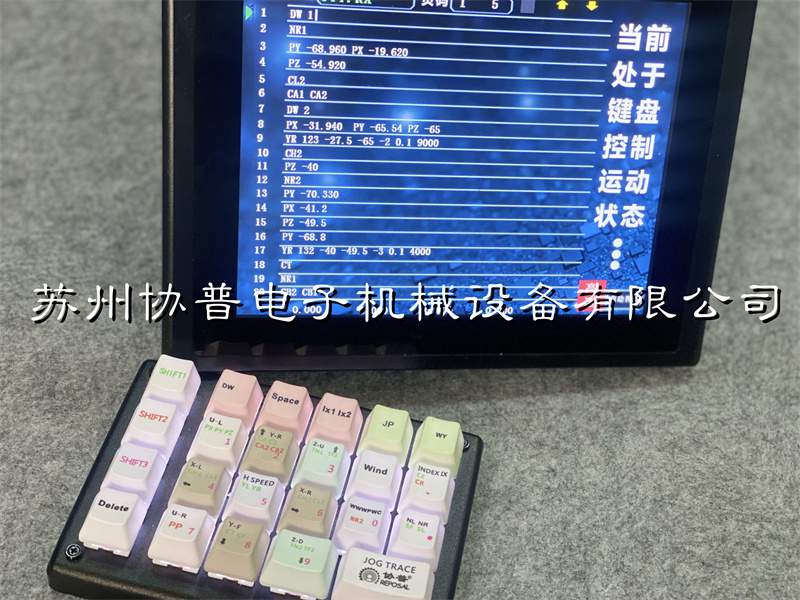

REPOSAL® Winder Releases Coded Teach Winder Control System

REPOSAL® Winding Machine Releases Code-Type Teaching Winding Machine Control System

REPOSAL® Winding Machine, a domestic coil intelligent manufacturing solution provider, has launched its new generation of code programming teaching type winding machine control system that is more open, intelligent and highly autonomous for coil winding enterprises - REPOSAL® Winding machine SP500-R5 system. Compared with the traditional dialog-type winding machine control system, the SP500-R5 system has achieved major breakthroughs in operation logic, technical architecture, and function implementation. Features.

The SP500-R5 system adheres to the concept of "openness and intelligence". Based on the functions of the traditional dialog-based winding machine control system, it integrates the actual needs of the winding factory, and is committed to realizing the coil winding process programming process from the traditional parameter dialog. A major innovation and upgrade from control to code teaching programming.

REPOSAL® winding machine releases special winding machine for frequency divider inductors

REPOSAL® winding machine releases special winding machine for frequency divider inductors

In daily life, have you ever noticed more than one horn on your car? And more expensive cars have more horns. According to normal people's thinking, the car as long as there is a horn can emit sound signals on the line, more horn is why? The reason is very simple, for example, the turn signal and the warning horn are completely different, the sound frequency is different, and the sound range of the speakers used for high and low is naturally different. A single speaker cannot play a full frequency sound, and a sound may require a combination of multiple channels of sound to achieve a clear cue.

Therefore, in order to make each speaker emit audio suitable for it, it is necessary to use a tool such as a frequency divider. In simple words, the frequency divider is a filter circuit composed of a capacitor and a frequency divider inductor coil wound by the frequency divider winding machine. The capacitor filters the low frequency to the tweeter, and the frequency divider inductor is wound by the frequency divider winding machine to filter the high bottom to the low frequency to the woofer, so as to distinguish the sound signals in different frequency bands in a sound. It has different sound frequency channels, high frequency sound channels can only pass high frequency sound, middle and low frequency sound the same. After the sound is distinguished, the sound is amplified and played in the corresponding sound amplifier, and finally we can get the most accurate audio we want.

Frequency dividers are divided into two categories, one is a power divider, and the other is an electronic divider.

The power divider is set in the speaker, the power amplifier in the speaker first amplifies the sound power, and then the power divider divides it into three audio signals, high, middle and low, and finally sends it to different speakers for playback. The advantage of this power divider is that it is simple and convenient to connect and use, but its disadvantages are also obvious, that is, its power consumption is large and the parameter deviation value is large, the error of the sound frequency is large, and its error is related to the impedance of the speaker, so it is not convenient to adjust.

REPOSAL® winding machine wire guided missile fiber winding forming technology has made a new breakthrough

REPOSAL ® winding machine wire guided missile fiber winding forming technology has made a new breakthrough

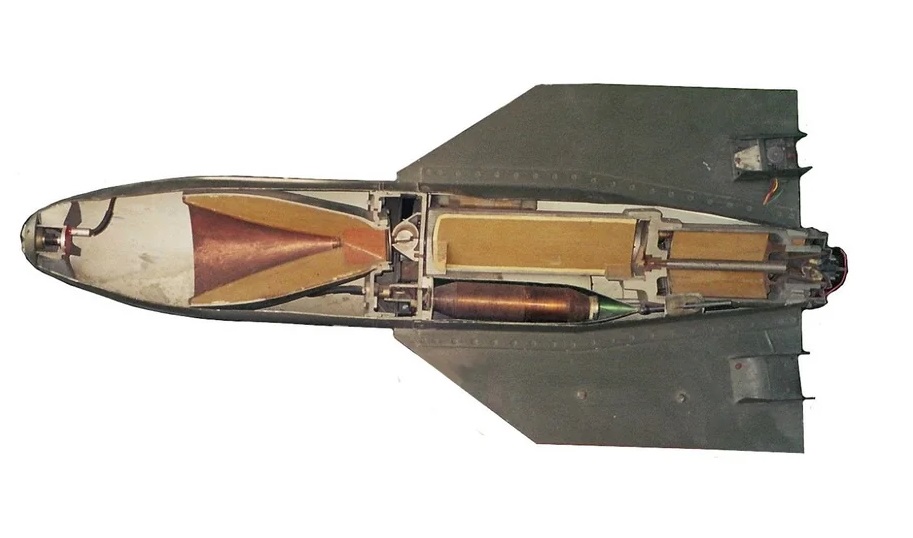

Fiber optic guidance of wire-guided missile is a closed-loop guidance and control of controlled missile by bidirectional transmission of information and control signals between missile and launcher using special fiber optics.

Fiber optic guidance belongs to the wire guidance of remote control guidance, its advantages are not only high precision, strong anti-interference ability, can be equipped with optical cable shaft, micro camera, missile launch tail will release fiber, can control the missile and obtain target information.

The winding and release technology of optical fiber is a key technology of optical fiber guidance. At present, we have not realized automatic production in the production of optical fiber winding in our country, so we rely on the winding technical personnel's proficiency very high. The cross-turns working procedure of the winding process is still mainly manual operation, low production efficiency, high error probability and low consistency.

In addition to other ways to solve the high speed release of optical fiber, an important way is to ensure the smooth release of optical fiber through optical fiber winding. Optical fiber winding technology is the requirement of the pointer to the optical fiber guided missile and the technology of winding the optical fiber on the spool. In view of the unique properties of optical fiber and the special use of optical fiber guided missile, optical fiber winding becomes a complicated technical problem. In the process of automatic winding, the technical difficulties related to the properties of optical fiber are as follows:

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released high-speed precision synchronous winding machine

Suzhou REPOSA Electronic Machinery Equipment Co., Ltd. releases high-speed precision synchronous winding machine

REPOSAL Winding Machine® Released Precision Automatic Paint Stripping and Wire Breaking Winding Machine

Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. releases

precision automatic paint stripping and wire breaking winding machine

In the inductive coil

winding process, the winding process requirements of the coil are quite

different.The diameter of the enameled wire varies from thin to thick, the

structure of the coil varies from disk to column, and the type of enameled wire

ranges from ordinary to self-adhesive wire. Therefore, for a coil winding

factory that does not emphasize competitiveness, the machine required is a

winding machine with a larger range of adaptation, but often a winding machine

with a larger range of adaptation is for each specific specification of coil

winding. Whether it is quality or efficiency, it is difficult to have targeted

competitiveness.

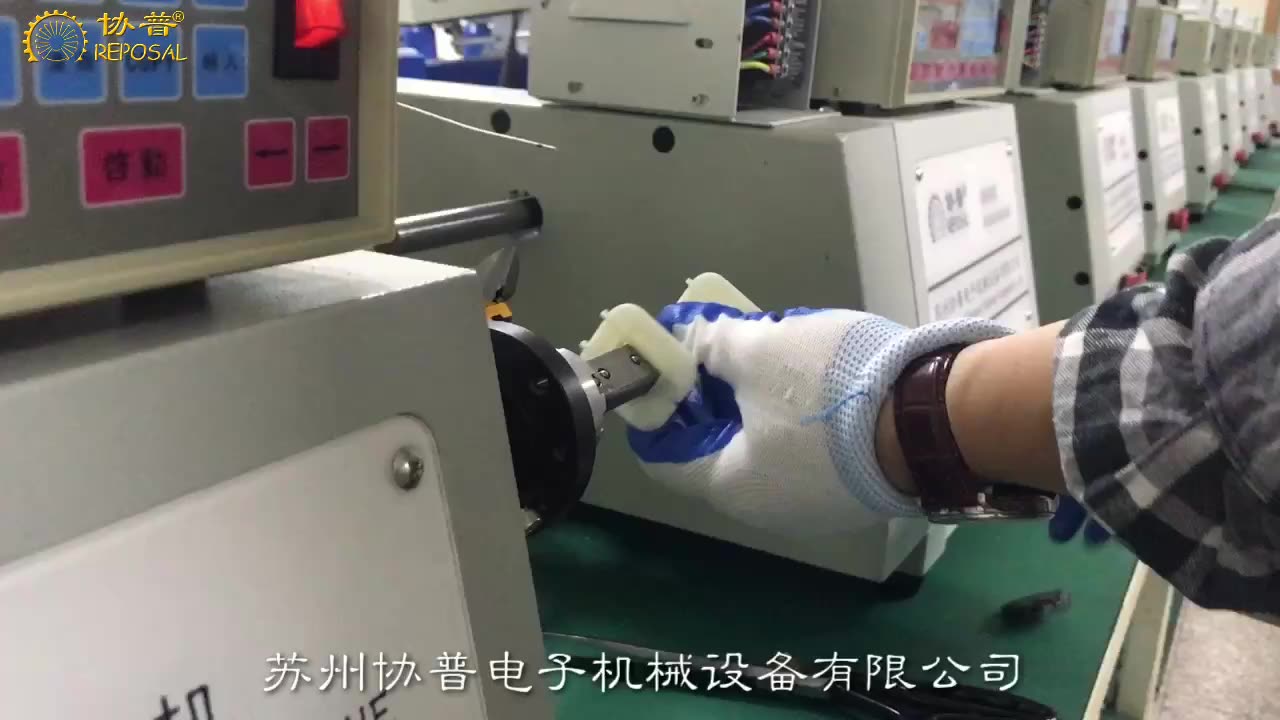

In order to keep our customers competitive in the induction coil winding process, we have developed this winding machine-precision automatic paint stripping and breaking winding machine in response to customer needs.

This model is mainly aimed at coils with a skeleton with a larger

enameled wire diameter. It has several features, one is the fast winding speed,

if it can maintain a faster winding shaft speed when the diameter of the

enameled wire is larger, and the other is the winding line is flat. Through

control and targeted structural optimization, a compact and consistent coil can

be stably wound. Third, there is an automatic paint stripping function. For

thicker non-direct welding enameled wires, adding this function is equivalent

to combining two processes Integrating into one process, the fourth is to add

the function of automatic disconnection.For thicker enameled wires, automatic

disconnection improves efficiency, strengthens consistency, and significantly

reduces the labor intensity of operators.

For

details, please refer to the video. The operation beat of this video is taken

during the acceptance of the machine. The entire operation process is fast and

stable, but in fact, there is still room for improvement in the efficiency of

fixing and dismantling the enameled wire head.

REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

REPOSAL® Winding Machine successfully overcomes the difficulty in the winding process of closed coils of fixed-length titanium plates with loops.

These tiny looped titanium plates are shown here, small metal structures approximately 12mm long, 4mm wide and 1.5mm thick, and have a row of four circular holes through them, two of which are for The main body pulls the suture through, and the other two upper holes are used for the passage of another group of seam lines. The structure is small in size, and it is necessary to form a closed connecting loop through the structural member, and the closed connecting loop is formed by twisting the yarn fibers of the loose structure. A closed high-strength braided coil is passed through the middle, which seems simple, but its core technology is reflected in the Loop, that is, a high-strength coil, which is woven evenly, tightly, non-woven, and without joints.

This kind of titanium plate with loops is divided into two types, fixed-length type and adjustable type, especially the fixed-length type, whose length ranges from 15mm to 60mm. It is necessary to wind this closed loop in the middle of a titanium plate with such a small volume. Coils, and because the number of colonies cannot exceed the standard, cannot be wound by hand, but must be wound by

equipment, which is extremely difficult to process. Its structural parts are small in size, and the diameter of the holes is only 1-1.5mm. It needs to form twisted yarns under such conditions, so this product has always been processed manually by hand, and its efficiency is low and consistent. Sex is hard to guarantee.

Because of the small size of the structure, the diameter of the hole is only 1-1.5mm, and it needs to form twisted yarn under this condition, so this product has been processed manually, and its efficiency is low. Consistency is difficult to guarantee.

REPOSAL® Winding Machine successfully developed this equipment according to the customer's request, completed the simultaneous formation of a closed loop (including fiber bundles with a loose structure) and passed it to the porous structural parts, and maintained the twisted structure, which greatly improved the closed loop. The winding efficiency, in addition to obtaining the incomparable consistency of pure hand-made, makes the product have the conditions for large-scale production.

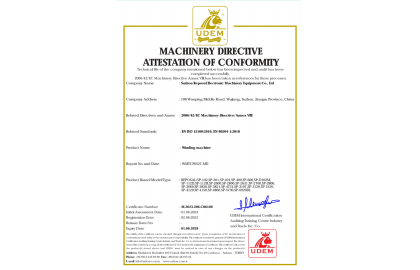

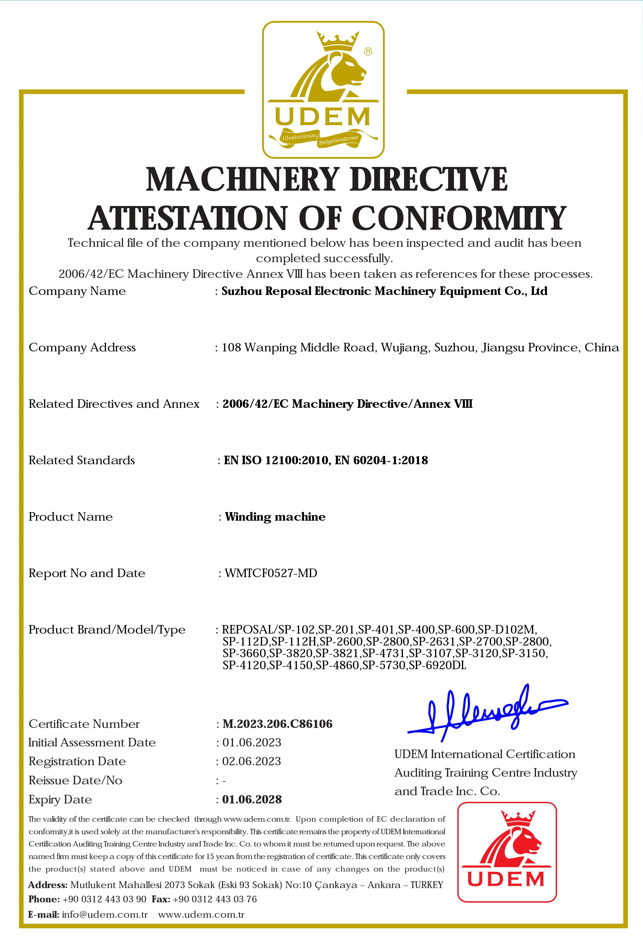

Congratulations on our winding machine successfully passed the EU CE certification, enter the international market

Congratulations on our winding machine successfully passed the EU CE certification, enter the international market

In response to the international market's requirements for the safety and quality of our winding equipment, recently, our series of winding machines have won the CE certification issued by the European Union certification body. This marks the recognition of the EU market for the |REPOSAL® winding machine, which means that our company has the ability to provide more professional and high-quality winding machine equipment for the international coil market, and further enhance the company's international competitiveness.

REPOSAL® Winding machine CE certification certificate

On the one hand, in response to the national "Belt and Road" call, REPOSAL® winding machine actively explore overseas markets. The passing of the EU CE certification not only opens the European market, but also the first step to open the global market, which means that the company's winding machine can be exported to various countries in the European Union, and the pursuit of free circulation of our winding equipment in the global scope has a positive effect on the company's expansion of overseas winding machine market and international business expansion. At the same time, it also provides safety and quality assurance for the sales of the winding machine in the domestic market, and enhances the brand influence of the winding machine.

Winding machine selection

In the narrow sense, the winding machine mainly refers to the winding machine of various enamelled wire coils, these coils may be transformers, relays, inductors, current transformers, various sensors, these coils can be seen everywhere in our lives, the common feature is to use enamelled wire winding, the difference is according to the design requirements, and the cost and efficiency requirements of industrial products, Its winding process is not corresponding, so derived from a variety of different winding machine, we show on the official website is only a part of the conventional winding machine, and some are customized, or special industries are not displayed, if you need to know, you can contact us.

Coils can be seen everywhere in our lives, such as the electric meter in the home, there are metering induction coils, trip coils in the circuit breaker, transformer coils in the community, various motor coils in industrial automation, various sensor coils, starting coils on the car, ignition coils, power motor coils on the bullet train, etc., it is no exaggeration to say that we live in a world of coils. There are so many coils, and the corresponding winding machines are different, so the winding machine is as important to the electrical world as the lathe is to the mechanical world.

There are so many types of winding machines, if you are not familiar with them, those selections have become a big problem, we now make a simple introduction from several aspects.

One is the winding method, which is generally divided into parallel winding machine, ring winding machine, and flying fork winding machine.

REPOSAL® machine research on tension control of transformer winding machine

In modern society, electricity is like a surging torrent, injecting strong impetus into our life and production. With the rapid development of China's science and technology and economy, the demand for electricity is increasing day by day, and the demand for transmission and distribution transformers, as an important cornerstone of the power system, is also rising.

The transformer is

the "heart" of the power system, and the winding coil inside it is a

key component of this "heart". The winding quality of the enameled

wire and insulating tape in the winding coil directly determines the

reliability of the transformer. The quality of this winding depends to a large

extent on the performance of the transformer winding machine.

With the sharp

rise in demand for transformers, the performance requirements for transformer

winding machines are becoming more and more demanding. A high-performance

transformer winding machine must not only meet the requirements of safety,

intelligence and high efficiency, but also have high-stability hardware,

easy-to-use software and excellent tension control.

However, at

present, the development of China's transformer winding machine industry is

still facing many challenges. The level of intelligence is relatively low, the

stability needs to be improved, and most of the high-end equipment relies on

imports, and the price is high.

REPOSAL® machine

is well aware of these challenges and has been working hard to improve the

performance and quality of its products. It continues to increase R&D

investment, is committed to improving the intelligent level and stability of

the winding machine, and strives to contribute to the development of the

industry.

When the

transformer winding machine is working, its coil is usually metal wire and

insulating paper, because they have a certain elasticity, the change of coil

conveying speed or roll radius will lead to the change of winding tension. For

example, in the winding and unwinding process, if the angular velocity of the

roll is constant, the change in the radius of the coil will cause tension

fluctuations. If the tension is too large, the coil may become thinner or even

break; If the tension is too small, the material will be unevenly arranged or

wrinkled, which will affect the quality of the transformer winding coil.

Compared with

foreign countries, China's existing domestic transformer winding machine has

deficiencies in tension control. Its tension is usually generated by mechanical

friction, which is not stable enough, which can easily lead to problems such as

sparse arrangement of wires and insulating tapes, and out-of-tolerance of the

outer diameter of the coil. In addition, compared with developed countries in

Europe and the United States, there is a gap in the overall development level

of China's transformer winding machine in terms of processing quality and

production efficiency.

The specific

performance is as follows: First, the processes such as wiring and wiring,

adding insulation layers rely on manual operation, which is inefficient and unstable

in quality. Second, the motor frequently starts, stops and reverses during the

winding process, the tension fluctuates greatly, the coil winding is irregular,

and the quality is difficult to guarantee. Third, the mechanical structure of

the domestic winding machine is relatively simple, and it is not competent for

the winding task of complex coils.

The development of

foreign transformer winding machines is relatively mature. The T-600AH

automatic transformer winding machine from Trishul.Engineers in India can wind

wires and insulating tapes synchronously, with high precision, stable tension

and high efficiency. The EFECO 800 automatic winding machine from

Tuboly.Astronic AG in Switzerland is even more excellent, with high-speed,

high-precision winding and an intelligent cable routing system. The products of

companies such as MTM in Canada, LAE in Italy and UPI in Korea also have high

intelligence and stability.

In terms of tension control research, many scholars have been exploring it in depth since the 90s of the last century. Bastogne T, Koc H and other scholars have pioneered theoretical research and modeling simulation. Entering the 21st century, more scholars are getting involved.

REPOSAL® machine

actively pays attention to the relevant research results at home and abroad,

and applies beneficial theories and technologies to the improvement of its own

products.

The winding

electronically controlled tracking system proposed by Mahawan B et al. in 2001

can still realize the trajectory tracking control of equipment under large

interference. In 2008, Wen P et al. designed a tension control scheme that

allowed the winding speed to be changed under a certain tension fluctuation

while maintaining quality. In 2010, Ponsart J C et al. applied the observer

theory to a transformer winding machine to improve the accuracy of tension

control. In 2017, Mahesh Ghate et al. optimized the tension system for a

specific winding machine and showed good robustness. In 2020, Ma Quanjin et al.

designed a dual-PID tension control system to address the tension fluctuation

problem in a 3-axis fiber winding machine applied with filament winding

technology.

Since the 70s of

the last century, China has begun to develop transformer winding machines, and

has achieved certain results through imitation and the efforts of scholars.

However, due to the monopoly of foreign core technologies, there is still a gap

with foreign countries, especially in terms of manufacturing processes and

control schemes.

At present, the domestic transformer winding machine is mainly in the semi-automatic stage. For example, F. of Dongguan Zongheng Electromechanical Technology Co., Ltd. TWloo CXL transformer winding machine for small and medium-sized transformer coil winding. The ZBR.800/1000/1200 multi-head automatic wiring winding machine of Jiangxi Yibo Automation Equipment Co., Ltd. can realize automatic wire arrangement.

REPOSAL® machine has been committed to promoting the

development of domestic transformer winding machine in the direction of full

automation and intelligence, and constantly optimizing its own manufacturing

process and control scheme.

However, there is still a breakthrough in the layout of

insulating tape and tension control in China, which greatly affects the quality

and production efficiency of the winding coil. Therefore, it is of great

significance to develop a control system that can automatically arrange wires

and insulating tapes with constant tension.

Tension control is a key technology for transformer

winding machine equipment. If the tension is too small, the wire or insulating

tape will slacken, accumulate and wrinkle; Excessive tension can cause it to

deform, stretch excessively, or even break. For transformer winding machines,

the tension control condition directly affects the compactness between the

layers of the winding wires.

At present, there are three main schemes of tension

control: manual, semi-automatic and fully automatic. The manual control needs

to be adjusted manually in stages, the semi-automatic control adjusts the

tension by detecting the change of the roll diameter, and the fully automatic

control is adjusted by directly measuring and feeding back the tension data by

the tension detector.

In the 80s of the last century, manual tension control

was mostly used in China, which was gradually replaced due to the increase in

demand. Since the beginning of this century, domestic scholars have conducted

in-depth research on the automatic tension control system for rewinding and

unwinding.

In 2005, Yang Tao and others from Tianjin Polytechnic

University used a PLC design scheme to accurately control the winding speed of

fine enameled wire. In 2010, Shi Yaoyao et al. studied the discontinuous coil

process and realized winding through the PID algorithm. In 2018, Zhiyong w et

al. established a constant tension control system for the problem of triaxial

fiber winding machine. In 2020, Song Chenliang et al. optimized the tension

adjustment effect of the winding machine through the pendulum tension

adjustment mechanism and the deformed PID control algorithm.

REPOSAL® machine has never stopped exploring tension

control solutions, and constantly tries to innovate to enhance the

competitiveness of products.

However, due to the complex structure of transformer

winding equipment and many influencing factors, the tension control system has

nonlinearity and coupling in different situations, which is still a difficult

point in equipment control. Constant tension control is very important to

ensure the quality of winding, so it is of practical significance to study the

constant tension control system suitable for industrial production.

In the winding coil structure of distribution

transformer, insulating paper tapes need to be arranged between the wire

layers, so the transformer winding coils are usually wound in layers. The

winding process is more complicated, the pilot wire is unwound and sent to the

spindle mold base, during which the oscillating roller adjusts the tension and

speed, and the spindle motor drives the spindle winding. Then the insulating

tape is unwound and sent to the spindle mold base, and multiple coil rolls

cooperate to adjust the tension. Finally, a plurality of motors work together

to drive the spools and other spools for the first layer of winding and arrangement,

after the completion of the wire motor reversal, the pressure roller shears the

insulating paper, the glue sprayer glues, and then the next layer of winding.

Taking Switzerland EFECO 800 transformer winding machine

as an example, its mechanical structure mainly includes spindle mold base,

winding spindle, glue spraying machine, etc. The winding spindle includes a

spindle motor, a reducer, etc., which drives the spindle to rotate and the foot

switch controls the start and stop. The wire winding mechanism has pay-off

wheels, adjusting handwheels, etc., and the insulating tape winding mechanism

has tension feedback devices. The wiring mechanism is composed of a wire spool,

a wire trolley, etc., which can achieve accurate wire arrangement.

For transformer winding machines, the tension control

directly affects the compactness between the winding lines. In practice, the

machining accuracy and the performance of the sensing device will have an

impact on the tension control. For example, the change of reel diameter, the

start-stop and acceleration and deceleration of the reel, the accuracy of

equipment manufacturing and assembly, the forward and reverse rotation of the

motor, and the hardware performance.

There are three ways to test tension. Directly using the

tension sensor to measure, the operation is simple but the limitation is large;

Floating roller tension detection, the measuring device is flexible but the

accuracy is low; Floating roller/feedback composite tension detection, high

accuracy but complex method.

In the process of arranging the transformer winding

machine, the adjustment of the wiring mechanism and the winding position and

the control of the wiring angle are the key to ensure the compactness of the

winding wire.

The cable arrangement mechanism measures the angle

through the rotary encoder on the spindle and transmits the data to the

controller, and the controller drives the wire motor after processing to

realize the speed coupling of winding and wire arrangement.

In the actual winding, the tension of the wire and the

insulating tape should be kept constant and cooperate with the wire

arrangement. In the automatic wiring control scheme, the main controller

controls the motor unit to work together, the spindle and the wiring mechanism

cooperate with the layered winding, the encoder feeds back the data in real

time, and adjusts the speed of each axis according to the control algorithm to

ensure the accuracy of the wiring.

The angle of the cable is very important, too large or

too small will affect the effect of the line. When winding, the line is

adjusted according to the change in angle, the feed rate is brought in, and the

overall trajectory is followed. Since winding is carried out in layers, divided

into wire layers (odd layers) and insulating layers (even layers), the wire

laying process can be divided into multiple stages and cycles.

The automatic wiring of the transformer winding machine

has high requirements for the motor control algorithm, which requires the

coordinated operation of the motors of each shaft and the close cooperation of

the drive actuator to jointly complete the automatic winding and arrangement of

the transformer coil. The common multi-motor cooperative control structures

include parallel synchronous control, master-slave motor control,

cross-coupling collaborative control, adjacent cross-coupling control and

deviation coupling step control, each with its own advantages and

disadvantages.

In conclusion, transformer winding machines are very

important in the power field. Although China has made certain achievements in

this field, it still needs to make continuous efforts to strengthen independent

research and development, improve the technical level, narrow the gap with

foreign countries, promote the development of the industry, and contribute more

to the power industry. REPOSAL® machine will continue to uphold the spirit of

innovation and enterprising, and make unremitting efforts to improve the

overall level of China's transformer winding machine.

REPOSAL®winding machine's advantages in crossover winding machines

REPOSAL has invested a lot of R&D efforts in the field of crossover coil winding machines and has achieved a series of remarkable results.

In terms of winding accuracy, through in-depth research and optimization of the wiring mechanism and control system, REPOSAL's divider coil winding machine can control the winding accuracy within a very small error range. For example, for the wire with a thin wire diameter, the winding machine can accurately wind according to the set number of turns and arrangement, to ensure that the position accuracy of each turn of wire reaches ±0.05 mm, which greatly improves the quality and performance stability of the coil, and makes the crossover more accurate in the audio signal processing.

In terms of improving winding efficiency, REPOSAL has developed a unique high-speed winding technology. Thanks to the use of an advanced motor drive system and an efficient drive, the winding speed of the winding machine is increased by 30% compared to conventional models. At the same time, combined with the intelligent control system, continuous and uninterrupted winding can be realized, which greatly shortens the winding time of a single coil. For example, a common divider coil that used to take about 10 minutes to be wound by hand, but only 3 to 4 minutes with REPOSAL's winding machine significantly improved production efficiency and provided strong support for large-scale production.

In terms of versatility, REPOSAL's crossover coil winders are highly adaptable. By designing replaceable winding dies and flexible parameter adjustment functions, it is possible to wind a wide range of divider coils with different specifications, shapes and parameter requirements. Whether it's a crossover coil for a miniaturized audio device or a crossover coil for a large professional audio system, high-quality winding can be achieved on the same winding machine. For example, for coil skeletons with different inner diameters, outer diameters and height requirements, the winding machine can quickly switch production modes through simple mold change and parameter setting to meet diverse market needs.

In addition, REPOSAL also pays attention to the research on the convenience and intelligence of the winding machine. A concise and easy-to-understand human-computer interface has been developed, so that operators can master the operation method with only simple training. At the same time, the winding machine also has intelligent fault diagnosis and early warning function, which can monitor the parameters in the winding process in real time, and once there is an abnormal situation, such as wire breakage, abnormal winding tension, etc., it will immediately send out an alarm and prompt the cause of the failure, which is convenient for the operator to deal with in time and reduce the risk of production interruption and equipment damage.