Congratulations on our winding machine successfully passed the EU CE certification, enter the international market

Congratulations on our winding machine successfully passed the EU CE certification, enter the international market

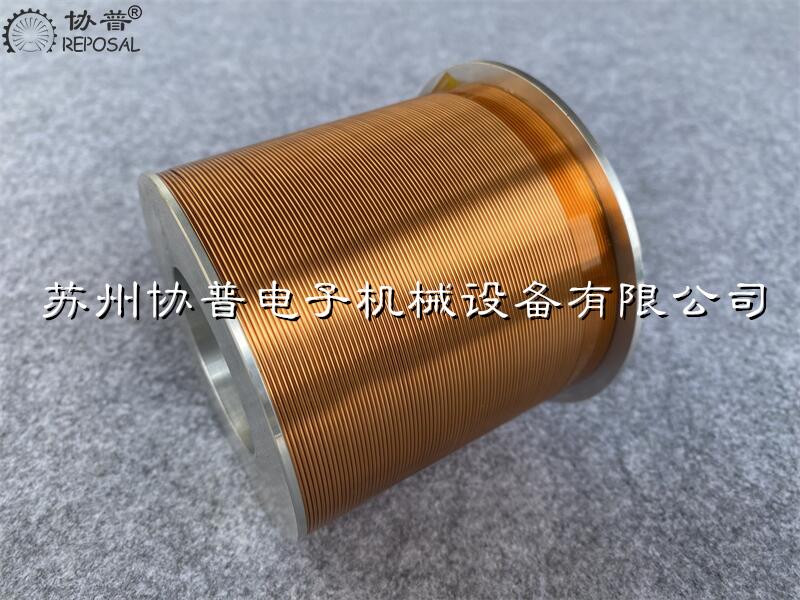

In response to the international market's requirements for the safety and quality of our winding equipment, recently, our series of winding machines have won the CE certification issued by the European Union certification body. This marks the recognition of the EU market for the |REPOSAL® winding machine, which means that our company has the ability to provide more professional and high-quality winding machine equipment for the international coil market, and further enhance the company's international competitiveness.

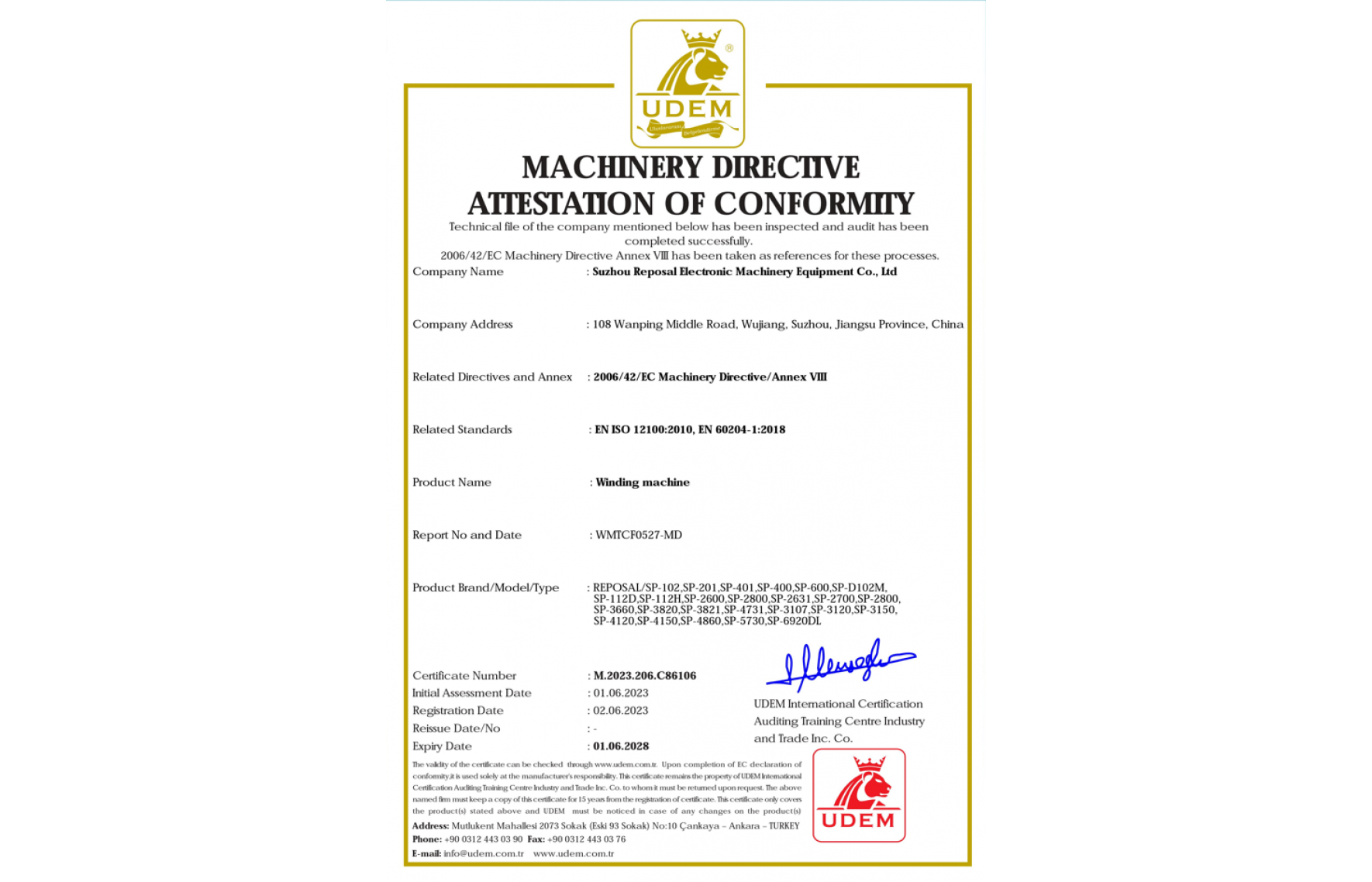

REPOSAL® Winding machine CE certification certificate

On the one hand, in response to the national "Belt and Road" call, REPOSAL® winding machine actively explore overseas markets. The passing of the EU CE certification not only opens the European market, but also the first step to open the global market, which means that the company's winding machine can be exported to various countries in the European Union, and the pursuit of free circulation of our winding equipment in the global scope has a positive effect on the company's expansion of overseas winding machine market and international business expansion. At the same time, it also provides safety and quality assurance for the sales of the winding machine in the domestic market, and enhances the brand influence of the winding machine.

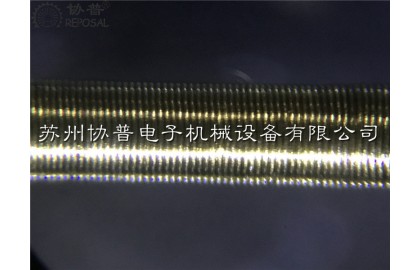

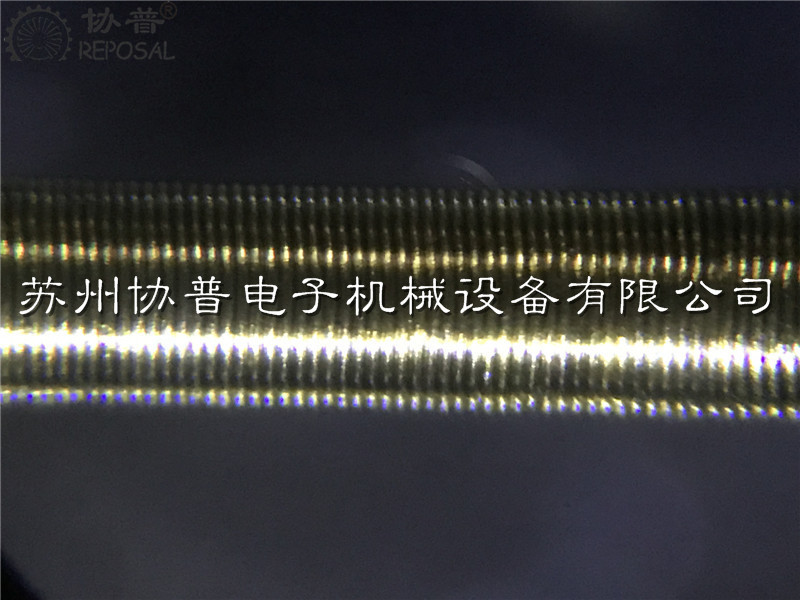

On the other hand, the |REPOSAL® winding machine has always been environmentally friendly. We strictly implement and implement the safety requirements and environmental protection standards in the research and development and manufacturing process, pay attention to equipment safety at the same time, but also the concept of environmental protection into every link of the winding machine, which coincides with the basic principle of CE. Not only that, the passing of CE certification, based on the strict inspection of the winding machine, our company in line with domestic and international standards at the same time, strictly control the export quality of the winding machine, the pursuit of higher standards and requirements, aimed at providing customers with better service and higher quality winding machine. The original intention of REPOSAL people is to provide customers with stable quality, so that our customers are competitive coil winding equipment, and strive to achieve the goal of corporate development and social responsibility!

The CE certificate of the EU certification not only proves the ability and determination of the |REPOSAL® winding machine, but also sets a higher goal and pursuit for the |REPOSAL® winding machine, laying a solid foundation for the company's future development.

Welcome domestic and foreign friends to discuss cooperation, the company is willing to work with all partners to develop together, benefit together, create brilliant!

About CE Certification

The "CE" mark is a safety certification mark that is regarded as a passport for manufacturers to open and enter the European market. CE stands for CONFORMITE EUROPEENNE (European Unity). The CE mark indicates that the goods comply with the health, safety and environmental protection standards of the European Economic Area (EEA).

In the EU market, the "CE" mark is a mandatory certification mark, whether it is the winding machine produced by enterprises within the EU, or the winding machine produced in other countries, in order to circulate freely in the EU market, it must be attached to the "CE" mark to show that the winding machine meets the basic requirements of the EU's "New method of technical coordination and standardization" directive. This is a mandatory requirement of the European Union law for the winding machine.

CE certification is limited to the basic safety requirements that the winding machine does not endanger the safety of humans, animals and goods, and the coordination directive only stipulates the main requirements, and the general directive requirements are standard tasks. Therefore, the accurate meaning is that the CE mark is a safety conformity mark rather than a quality conformity mark. Are the "main requirements" that form the core of the European directive.