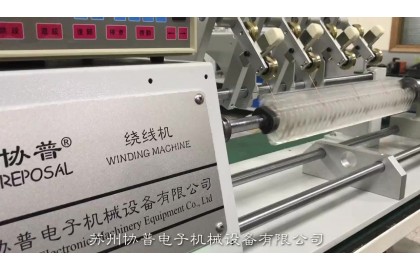

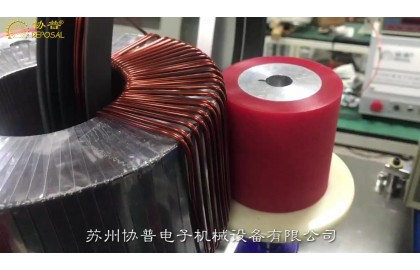

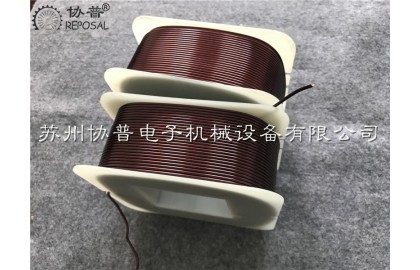

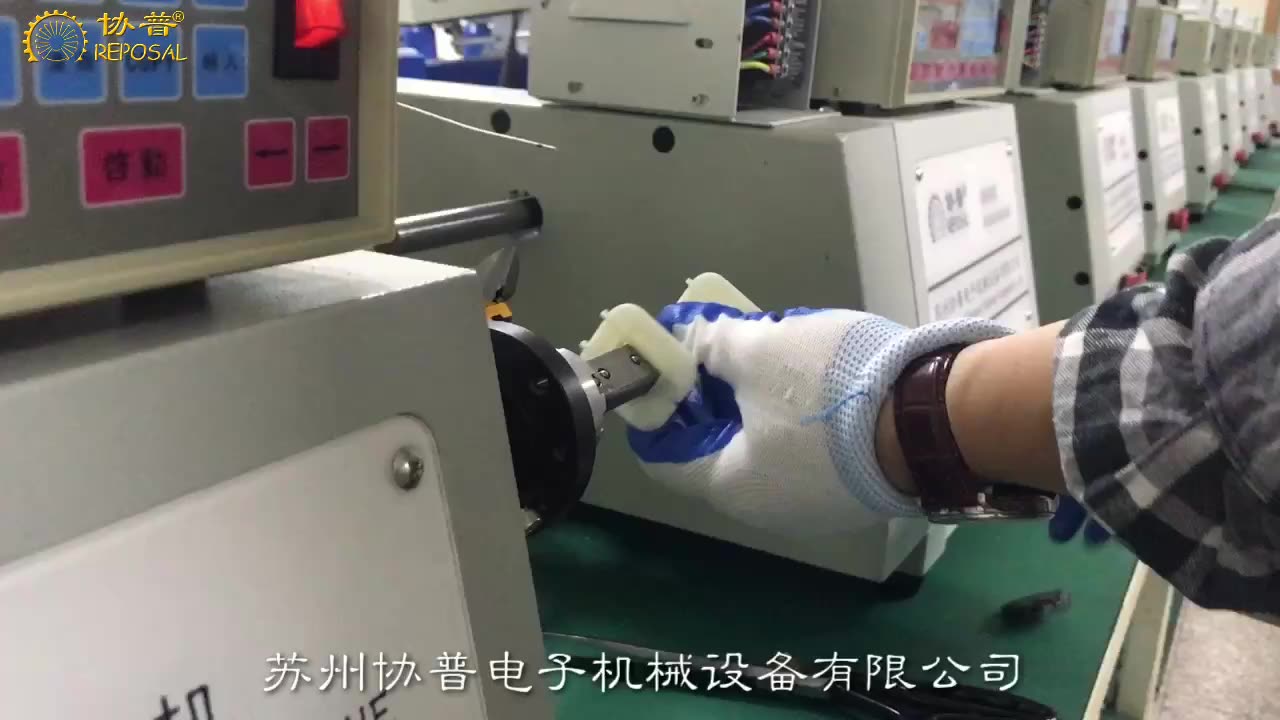

REPOSAL Winding Machine® Released Precision Automatic Paint Stripping and Wire Breaking Winding Machine

Suzhou REPOSAL Electronic Machinery Equipment Co., Ltd. releases

precision automatic paint stripping and wire breaking winding machine

In the inductive coil winding process, the winding process requirements of the coil are quite different.The diameter of the enameled wire varies from thin to thick, the structure of the coil varies from disk to column, and the type of enameled wire ranges from ordinary to self-adhesive wire. Therefore, for a coil winding factory that does not emphasize competitiveness, the machine required is a winding machine with a larger range of adaptation, but often a winding machine with a larger range of adaptation is for each specific specification of coil winding. Whether it is quality or efficiency, it is difficult to have targeted competitiveness.

In order to keep our

customers competitive in the induction coil winding process, we have developed

this winding machine-precision automatic paint stripping and breaking winding

machine in response to customer needs.

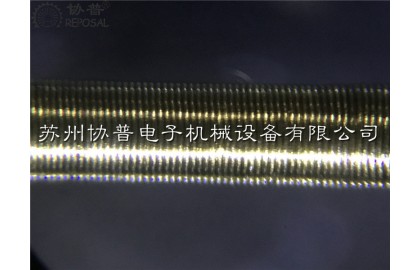

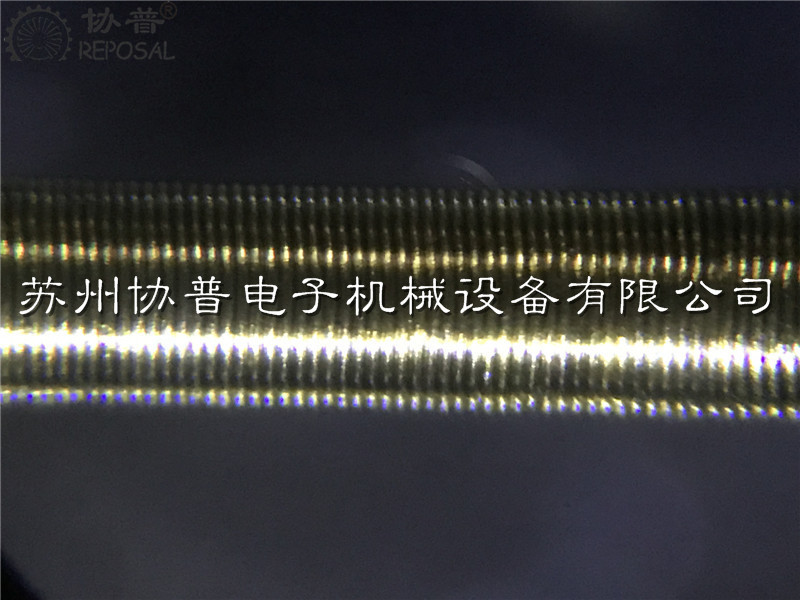

This model is mainly aimed at coils with a skeleton with a larger

enameled wire diameter. It has several features, one is the fast winding speed,

if it can maintain a faster winding shaft speed when the diameter of the

enameled wire is larger, and the other is the winding line is flat. Through

control and targeted structural optimization, a compact and consistent coil can

be stably wound. Third, there is an automatic paint stripping function. For

thicker non-direct welding enameled wires, adding this function is equivalent

to combining two processes Integrating into one process, the fourth is to add

the function of automatic disconnection.For thicker enameled wires, automatic

disconnection improves efficiency, strengthens consistency, and significantly

reduces the labor intensity of operators.

For details, please refer to the video. The operation beat of this video is taken during the acceptance of the machine. The entire operation process is fast and stable, but in fact, there is still room for improvement in the efficiency of fixing and dismantling the enameled wire head.

Related Post

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Horseshoe hollow cup motor coil and winding machine

Horseshoe hollow cup motor coil and winding machine

In recent years, China has paid more and more attention to hollow cup motor and automatic winding technology, and has made good progress and breakthroughs in the research and development and manufacturing of winding machine equipment.

One of the key reasons for the impact on the performance of the motor is the rotor coil in the motor, the rotor in the hollow cup motor has no iron core, small inertia, excellent functionality and a wide range of applications. In addition, in the research and development of coil winding equipment, the saddle-shaped coil arrangement is regular, and the utilization efficiency of magnets is high.

Compared with the old traditional motor with an iron core, the energy conversion efficiency is significantly higher than the latter, and the reaction speed will be much faster, and the hollow cup motor has high efficiency, fast response speed and stable performance. Because the hollow cup motor has no lag, additional electromagnetic interference is low, very high motor speed can be achieved, and the speed setting is sensitive at high speed, so it has relatively stable and stable performance. In addition, the energy density of the hollow cup motor is much greater than that of other motors, and the weight will be much less than that of an iron core motor with the same power.

Now according to the forming method of the coil, in the hollow cup motor coil, its production technology can be roughly divided into two process routes: winding production technology and one molding production technology.

Compared with the two methods, the first winding production technology is more complex, and the efficiency of winding the coil is relatively low. In order to improve the winding efficiency of coil production, the winding machine can be added to the production process of one molding. According to the hollow cup coil shape and winding method, the common hollow cup winding method can be divided into three kinds of parallel straight winding, saddle winding and oblique winding. The first parallel straight winding is generally used for hollow cup motor winding with relatively few turns. The last two are the two coil winding processes commonly used by the relatively advanced hollow cup motor manufacturers abroad.

REPOSAL® has successfully released a radiofrequency ablation catheter winding machine

Radiofrequency ablation has ablation and cutting functions, and the main therapeutic mechanism is thermal effect. Radio frequency refers to radio frequency, frequency up to 150,000 times per second of high frequency vibration, but it does not belong to the division of bands in radio communication.

The coiling process is completed by continuous test and optimization of the coiling machine.

The working flow of this winding machine is as follows:

1. The active wire feeding device of the radiofrequency ablation catheter winding machine ensures that the wires are constantly connected and not tied.

2. Double fold section A measurement line.

3. Manual folding head.

4. Manually fix the thread head (Two schemes are tentatively proposed for fixing the thread head)

4.1 Fix the starting position with glue. The fixture locks the PEEK tube.

4.2 Kangtong wire is hung on the feature of steel pipe. Glue to fix the ends after wrapping.)

5. Press the start button of the radiofrequency ablation catheter winding machine to wrap.

6.(During the winding process of the radiofrequency ablation catheter winding machine, both AB and AB segments have adjustable tension)

7. Wrap the jump grid to the specified position (the specific hop length can be set, and the rotation Angle can be set.

8. After the radiofrequency ablation catheter winding machine is finished, the feeder stops at the end and maintains tension.

9. Fix the end of the line by manual dispensing

10. Both ends of the radiofrequency ablation catheter winding machine are coaxial, and the rotation direction is synchronized.

11. Adjustable pre-drawing force is required at both ends of the locking shaft core.

Transformer winding crepe paper | Transformer winding crepe paper | Transformer winding crepe paper

Transformer insulating crepe paper has good mechanical strength, high withstand voltage strength, wrinkles on the surface, and a certain degree of toughness. Moreover, it is easy to cut. After the transformer is wound and formed, it still maintains a certain strength in the oil immersion of the rear tooling. This feature can very well protect the enameled wire of the transformer from being squeezed and broken, that is, it meets the insulation requirements. It also meets the mechanical performance requirements.

Therefore, it is widely used for transformer insulation. Generally used in transformers, but less used in transformers, because the core structure of transformers is annular, because the surface of the insulating crepe paper has wrinkles and friction is large, so the annular wrapping machine is used. Winding is more difficult, so in general, if crepe paper is required for the transformer coil, manual winding is used. We have successfully overcome this problem by improving the details.

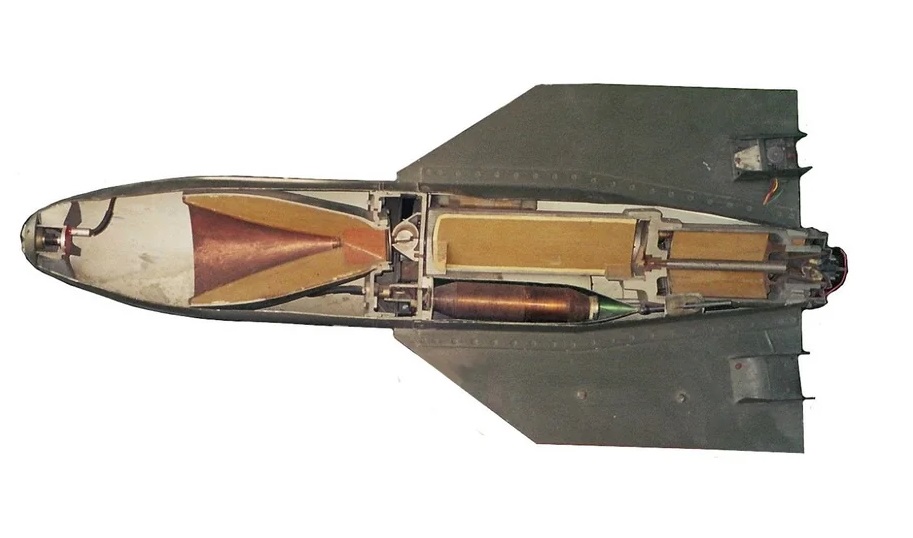

REPOSAL® winding machine wire guided missile fiber winding forming technology has made a new breakthrough

REPOSAL ® winding machine wire guided missile fiber winding forming technology has made a new breakthrough

Fiber optic guidance of wire-guided missile is a closed-loop guidance and control of controlled missile by bidirectional transmission of information and control signals between missile and launcher using special fiber optics.

Fiber optic guidance belongs to the wire guidance of remote control guidance, its advantages are not only high precision, strong anti-interference ability, can be equipped with optical cable shaft, micro camera, missile launch tail will release fiber, can control the missile and obtain target information.

The winding and release technology of optical fiber is a key technology of optical fiber guidance. At present, we have not realized automatic production in the production of optical fiber winding in our country, so we rely on the winding technical personnel's proficiency very high. The cross-turns working procedure of the winding process is still mainly manual operation, low production efficiency, high error probability and low consistency.

In addition to other ways to solve the high speed release of optical fiber, an important way is to ensure the smooth release of optical fiber through optical fiber winding. Optical fiber winding technology is the requirement of the pointer to the optical fiber guided missile and the technology of winding the optical fiber on the spool. In view of the unique properties of optical fiber and the special use of optical fiber guided missile, optical fiber winding becomes a complicated technical problem. In the process of automatic winding, the technical difficulties related to the properties of optical fiber are as follows:

REPOSAL ® winding machine has successfully realized the coil preparation process of the frameless capillary magnetic liquid acceleration sensor

In particular, the non-magnetic material in the magnetic liquid will be subjected to a magnetic field force in the non-uniform magnetic field, which makes many magnetic liquid acceleration sensors can be designed based on this characteristic.

These characteristics make the magnetic liquid acceleration sensor has many advantages compared with the traditional acceleration sensor, such as no wear, high sensitivity and simple structure.

However, most of the existing magnetic liquid acceleration sensors use solid mass blocks as non-magnetic substances, and use coils to detect changes in inductance under different accelerations to obtain output signals. However, its disadvantage is that it leads to complex magnetic circuit and poor sensor stability.

A new solution emerged -- the capillary magnetic liquid acceleration sensor, good stability, simple magnetic circuit, accurate and reliable measurement results and long service life.

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

REPOSAL Winding Machine® Released Tandem flat-wound winding machine

General technical conditions for parallel winding machine SJ/T 10313—92

People's Republic of China Electronics Industry Standard

General technical conditions for parallel winding machine sj/t 10313—92

General specification of parallel winding machine

1 Subject content and scope of application

This standard specifies the technical requirements, test methods, inspection rules and markings, packaging, transportation and storage requirements for parallel winding machines.

This standard is applicable to parallel winding machines whose skeleton cross-sectional shape is round or rectangular coils.

This standard does not apply to winding machines that wind toroidal, honeycomb, and saddle coils.

2 reference standards

GB191 packaging, storage and transportation pictorial mark

GB4006.1 winding coil cylindrical bobbin type size

GB4006.2 winding coil tapered coil type size

GB4215 Measurement of noise power level of metal cutting machine tools

GB5080.7 Equipment Reliability Test The verification test plan for failure rate and mean time between failures under the assumption of constant failure rate

GB6109.1 enameled round winding wire part one general regulations

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

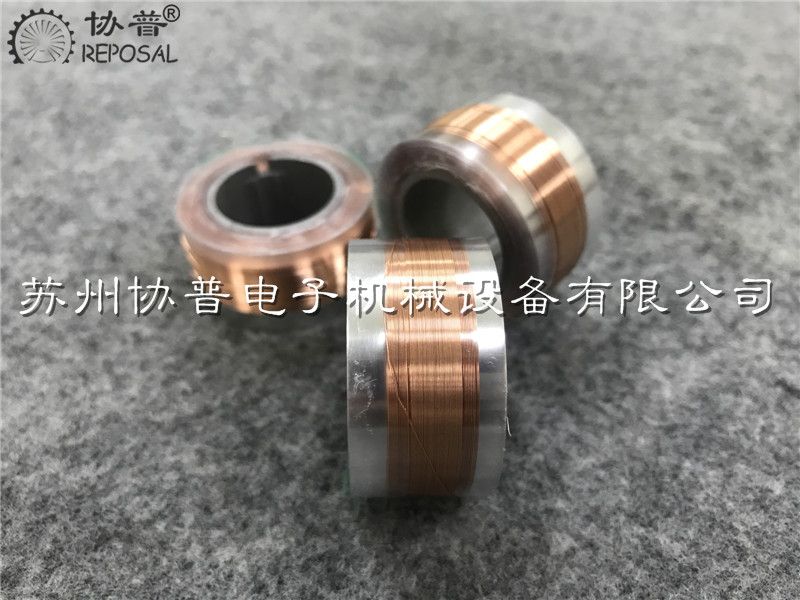

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

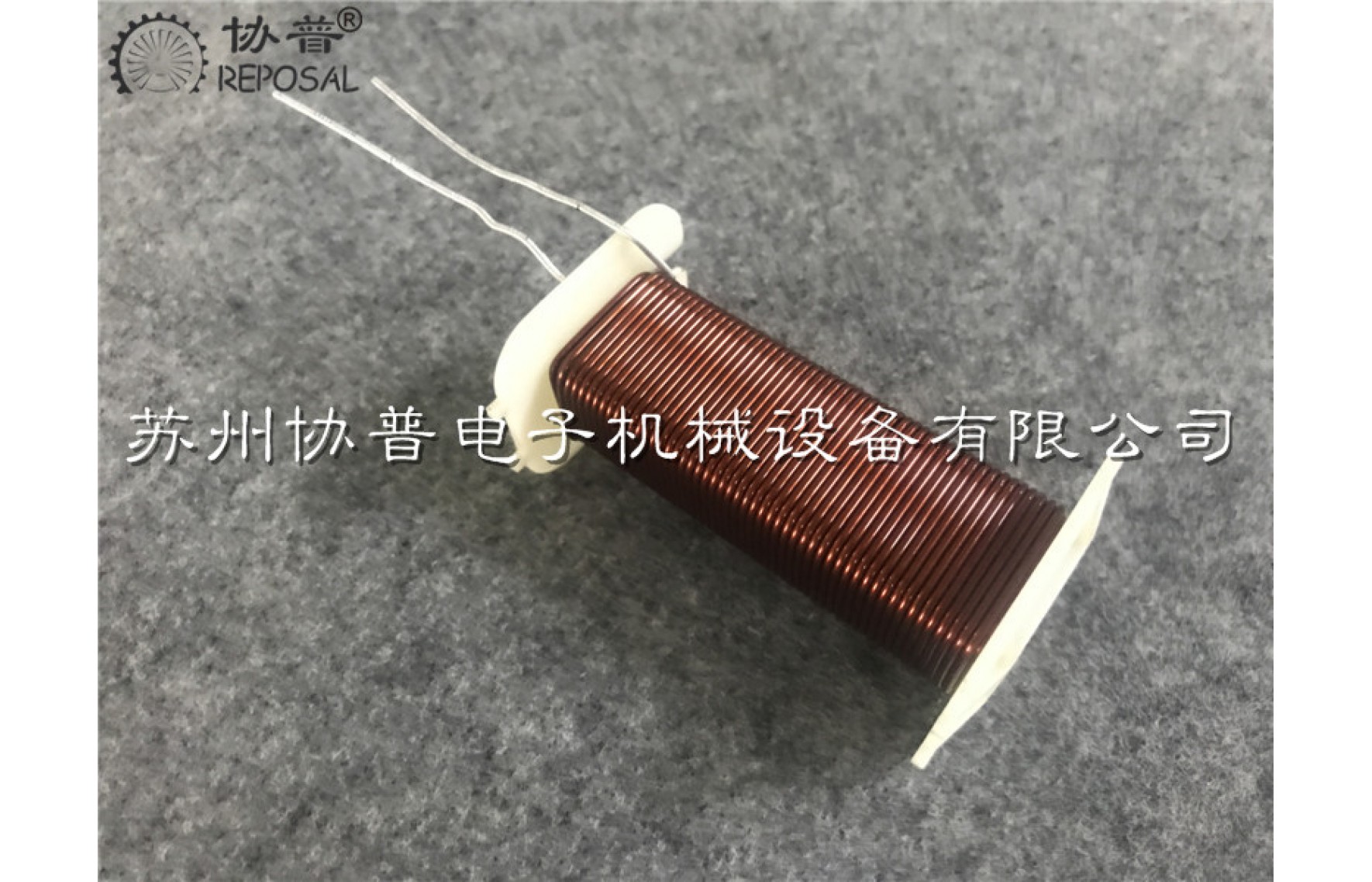

Precision C-shaped coil winding machine

Precision C-shaped coil winding machine

Precision winding machine

Precision large torque winding machine:

With the continuous improvement of the technical level, people have more and more stringent requirements on the winding of transformer coils, hoping that each enameled wire can be like

The ideal sorted arrangement has the following benefits.

First, in the case of neat arrangement, the enameled wire with limited space accounts for a much larger proportion than the irregular arrangement

The second is the wire saving.To achieve the same energy density, less neatly arranged copper wire is consumed than if it is neatly arranged.

The third is the consistency of the product, because the neat wiring, so the copper consumed by each coil is more consistent.

Of course, there are advantages of heat dissipation and high temperature resistance.

Despite the above advantages, but for a long time, it was thought that the equipment manufacturers were powerless, and it was difficult for people to do it smoothly with machines.When there is such a requirement, people usually use manual processing.

Wire the cable by hand, hit an irregular place, stop, handle it manually, and then slowly wind it.For a long time, people have done this.

Now all this has changed. We have successfully developed a precision large torque winding machine . Through control and mechanical optimization, we have done so.

It takes a long time, but now only a simple training is required.The precision large torque winding machine makes what was impossible before possible.

Precision hollow coil winding machine

Precision hollow coil winding machine

Influence of low enameled stress on formability in the process of winding enameled wire by winding machine

1 The formability of the enameled wire The mechanical properties of the enameled wire are divided into the mechanical properties of the conductor and the paint film. In the process of winding the enameled wire, in the wire embedding process, and in the electrical products using the enameled wire coil as a component, mechanical stress acts on the enameled wire during operation, so the enameled wire may be elongated and the paint film is damaged. etc. phenomenon. Therefore, enameled wire has the requirements of elongation, rebound angle, softness, tensile strength, paint film elasticity, paint film adhesion and scratch resistance.

1.1 Mechanical properties of conductors: softness, elongation, rebound angle, and tensile strength.

Elongation reflects the plastic deformation of the material and is used to assess the ductility of enameled wires. The springback angle and softness reflect the elastic deformation of the material and are used to evaluate the softness of the enameled wire. The tensile strength is related to the recovery recrystallization degree of the conductor and the grain size of the recovered tissue. The tensile strength, softness and elongation reflect the quality of the copper material and the degree of enameled annealing, which have a great impact on the quality of the winding. great relationship.

In the process of enameled wire coating, if the number of paint passes and the number of loops is too large, and the diameter of the guide wheel is not large enough, the wire will be continuously deformed by alternating tension and compression, resulting in the distortion of the lattice. It breaks easily when stretched. When the enameled wire is running, the wire is subjected to excessive tension, which will make the wire thinner. At this time, due to the displacement of atoms or ions on the lattice due to sliding, residual internal stress has been formed, so the wire is brittle and elongated. rate and softness rate decreased.

General debugging method of winding machine

General debugging method of winding machine

Some people look at the winding machine and feel a bit like a lathe, but in fact the winding machine has to wind a neat coil. Compared with the smoothness of the lathe, it is much more complicated, so we will find that the lathe has a long time ago The national standard has quantitative standards for its various indicators, but the winding quality of the winding machine has many condensing factors and it is difficult to quantify.

It is precisely because of the above reasons that at first I feel that the winding machine should be very easy to debug, but after the facts, I will be a little frustrated. Although the winding machine debugging is indeed more complicated than imagined, but if we master the basic laws After that, it's not difficult to practice more.

First of all, we must have a preliminary understanding of the structure of the winding machine, otherwise, we are not familiar with the structure of the winding machine, and there is no professional technical personnel training. Automatic debugging of the winding machine will be incompetent.