About Us

I. Toroidal Coil Winding Machine Series

Capable of

mirror-finish arrangement for thin wires (0.08mm), neat arrangement for thick

wires (5mm), and mirror-finish arrangement for parallel winding of 5 strands of

1mm enameled wire.

1.

Ultra-Precision Wire Arrangement, Solving Industry Pain Points

Equipped with

cutting-edge precision winding capability in the industry, it can wind 0.08mm

ultra-fine enameled wire into toroidal coils with a "mirror

effect"—the wire arrangement is tight and flat without wire jumping or

overlapping, resolving the common industry issue of conventional toroidal

winding machines that "can wind but cannot achieve neat arrangement".

Meanwhile, it enables high-precision winding of large-diameter toroidal coils

(0.4mm wire diameter, 0.5–1m diameter), producing well-formed coils with

distinct wire strands that far exceed the performance limits of similar

equipment.

2. Leading

Multi-Wire Parallel Winding Technology, Easily Handling Complex Processes

Supports

synchronous parallel winding of 5 strands of 1.0mm wire while achieving mirror-level

wire arrangement precision. It features accurate synchronous tension control

for multiple wires, eliminating issues such as uneven tension and wire abrasion

during the winding process. This meets the complex production requirements of

high-end precision toroidal coils, with technical strength far above the

industry average.

3. Mature and

Reliable, Backed by Dual Credentials of Cases and Experience

Leveraging

extensive industry application cases and mature design solutions, the equipment

boasts stable structure and standardized processes. A standardized workflow has

been established from core component selection to whole-machine debugging,

paired with comprehensive supporting services. It can quickly respond to

personalized toroidal coil production needs across different industries,

realizing immediate production upon delivery with dual guarantees of quality

and efficiency.

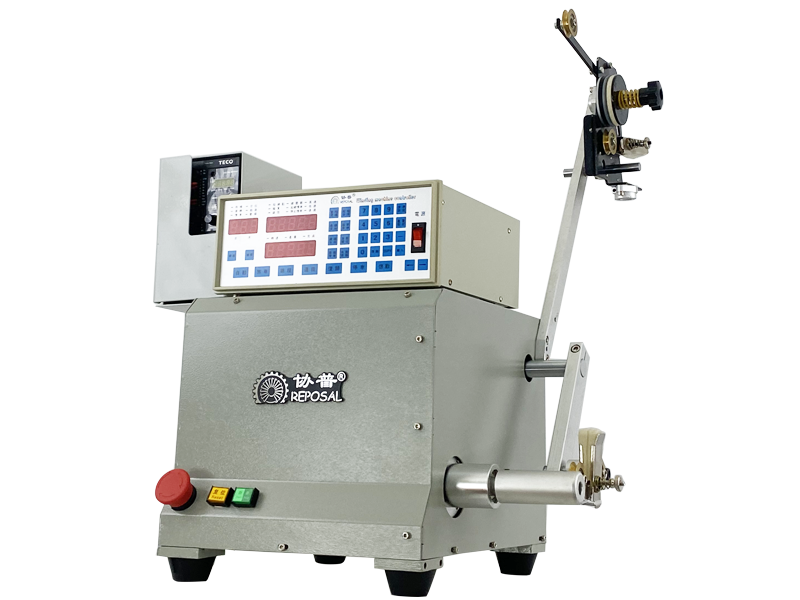

II. Economical SP-102 Series

Cost-effective,

fully functional, and versatile for diverse scenarios. Compatible with wire

diameters ranging from 0.03mm to 1.8mm.

1. Unmatched

Cost-Effectiveness

Sheet metal body

controls costs; core components (motor/bearing/frequency converter) adopt

standard parts, ensuring standardized processes, low failure rates, and easy

operation for beginners.

2. Ultra-Simple

Operation

Touch screen

paired with preset parameter library enables proficiency in 30 minutes;

power-off memory function plus 999 groups of process storage allows quick

specification switching, ideal for small-batch and multi-variety production.

3. Reliable Basic

Precision

Accurate winding

count, neat wire arrangement, and automatic deceleration for coil finishing

reduce manual rework, satisfying regular production needs of transformers,

inductors, and filters in medium and small batches.

4. Stable and

Durable

Mature control

logic ensures strong anti-interference performance; optional 600W DC brushless

motor with a maximum speed of 6000RPM, powered by standard 220V household

electricity, featuring low maintenance costs.

5. Strong

Adaptability

Compatible with

various wire diameters and small-sized toroidal workpieces, supporting

cross-slot winding. No equipment replacement is required for specification

changes, making it suitable for startups and small factories expanding

production capacity.

6. Flexible

Configuration

Tailored to

different budgets and requirements, it offers optional DC brushless/AC

frequency conversion systems and can be equipped with tensioners/line

arrangers. Cost-effective upgrades support the transition from semi-automatic

to quasi-automatic production.

7. Low-Threshold

Production Launch

Compact size,

minimal floor space, and easy transportation, combined with low procurement and

maintenance costs, ensure fast return on investment, perfect for users with

limited budgets.

Additional

Highlights

Power-Off Resume

Winding: Resumes winding after power restoration, reducing raw material and

labor time waste.

Wide Application Coverage: Fully covers common scenarios including high-frequency transformers, inductors, filters, and small-sized coils.

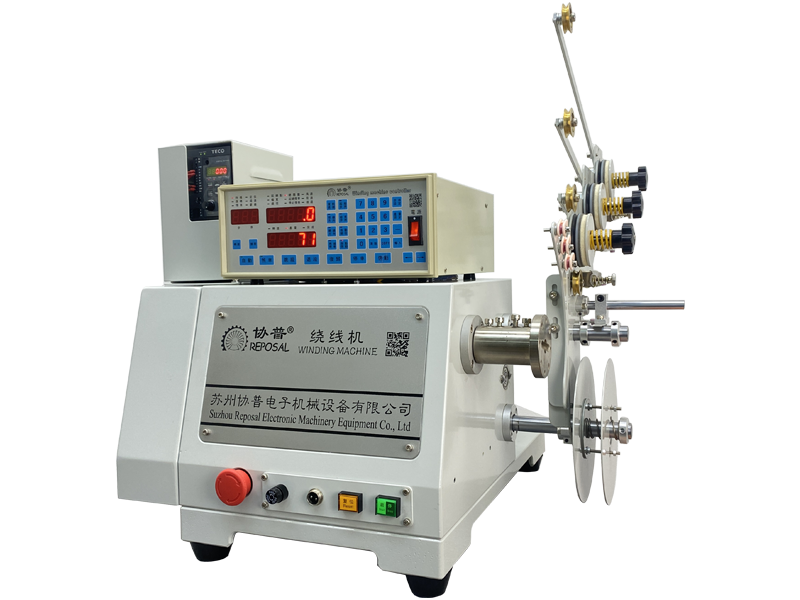

III. Standard SP-112D Series

Desktop design

with high rigidity and precision, suitable for scenarios requiring certain

accuracy and quality for small-volume coils. Compatible with wire diameters

ranging from 0.02mm to 2.0mm.

1. High-Rigidity

Body, Maximum Stability

Both the cabinet

and base adopt integrated casting technology, paired with a large bearing span

design. Its mechanical strength far surpasses sheet metal models, featuring low

vibration and noise during operation, and maintaining stable precision even

during 24-hour continuous operation.

2.

High-Efficiency Output, Surging Productivity

Fast mechanical

operation speed, combined with high-quality motors and precision transmission

structures, increases winding efficiency by over 40% compared to entry-level

models, easily meeting the needs of medium and small-batch large-scale

production.

3. Flexible

Configuration, Wide Adaptability

Supports

diversified customized configurations (e.g., pneumatic tailstock, tensioner,

multi-specification chucks), compatible with various wire diameters and

small-sized special-shaped workpieces. The small-load clamping structure and

cantilever beam design ensure smooth wire feeding without abrasion, suitable

for winding coils of transformers, inductors, and other products across

multiple scenarios.

4. User-Friendly

Operation, Easy to Master

Optional touch

screen paired with a dedicated motion control system for winding machines,

supporting storage of multiple process parameters. The power-off memory

function eliminates repeated debugging; the teach-mode programming design

allows beginners to operate proficiently in 30 minutes, ensuring fast and

efficient production switching.

5. Balanced

Cost-Effectiveness, Budget-Friendly

Comprehensively

upgraded performance compared to entry-level models, yet priced far lower than

precision models. It perfectly caters to users with limited budgets pursuing

stable quality, balancing production efficiency and cost control.

6. Durable and

Easy to Maintain, Long-Term Peace of Mind

Core components adopt high-quality standard parts; the modular design facilitates later maintenance and replacement, featuring low failure rates and maintenance costs, minimizing unplanned downtime and ensuring production continuity.

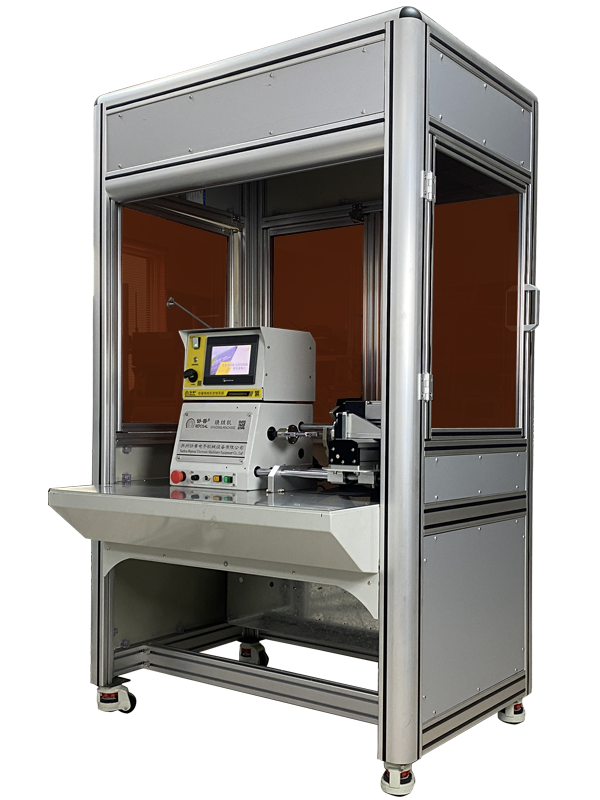

IV. Precision SP-112H Series

Benchmarked

against German VC winding machines, with high precision and strong process

rigidity. Capable of winding enameled wires with diameters ranging from 0.03mm

to 7mm.

1. Ultra-Rugged

Rigidity, Stable Performance Under Heavy Loads

Core components

of the whole machine (headstock, tailstock, simply supported beam bracket)

adopt thickened integrated casting technology, with a radial load-bearing

capacity of 500kg. It features low vibration and noise during operation,

maintaining stable precision even during 24-hour continuous heavy-load work,

suitable for winding large-diameter wires.

2. Top-Tier

Precision Configuration, Zero Quality Deviation

Equipped with a

Morse taper tailstock with high rotational precision, achieving wire arrangement

neatness far exceeding industry standards. Combined with a high-precision

multi-axis motion controller and servo drive system, it realizes deviation-free

multi-axis coordinated interpolation, ensuring consistent coil turns and

spacing.

3. Full-Scenario

Adaptability, Covering All Complex Processes

Supports winding

of disc-shaped, cylindrical, and special-shaped coils, perfectly matching the

high-precision requirements of new energy vehicle electronic coils, brake

coils, etc. It is compatible with various wire diameter specifications, capable

of accurately processing both ultra-fine and thick enameled wires without

replacing core equipment.

4. Modular

Customization, Function Expansion on Demand

Optional rich

functions including hot air treatment, grease coating, online laser wire

diameter detection, and series-wound tensioners, supporting closed-loop

real-time tension control to effectively reduce wire breakage and material

waste. Reserved interfaces for external equipment enable connection with MES systems

and visual inspection modules, meeting the needs of intelligent manufacturing

upgrades.

5.

High-Efficiency Mass Production Attributes, Significant Cost Reduction and

Efficiency Improvement

The multi-axis

linkage design greatly shortens idle travel time; preset process parameter

libraries can be called during model switching, eliminating repeated debugging.

Paired with optional automated loading and unloading modules, the

single-machine productivity is increased by over 50% compared to standard

models, reducing the comprehensive cost of mass production by 30%.

6. High

Adaptability + Long Service Life, Benchmark for Cost-Effectiveness

Core components

adopt high-quality standard parts; the modular design facilitates maintenance

and replacement, featuring low failure rates and controllable maintenance

costs. It not only meets high-end precision production needs but also offers

superior cost-effectiveness compared to peer precision models, making it the

optimal solution for mid-to-high-end production capacity upgrades.

7.

Industry-Tailored Optimization, First Choice for High-End Scenarios

Optimized design

for high-standard fields such as new energy vehicles and precision electronics,

delivering coils with outstanding electrical performance and mechanical stability.

It resolves the cumulative error issue in multi-turn and multi-layer winding,

serving as the core equipment for high-demand coil production.

V. Micro Coil Winder SP-D102M Series

Benchmarked

against American MCS micro coil winding machines, capable of winding wires as

thin as 0.007mm.

The REPOSAL

SP-D102M series micro coil winding machine is dedicated to the processing and

manufacturing of precision micro coils, with core technical indicators matching

the standards of American MCS products. In the market landscape, we maintain a

positive competitive and complementary cooperation relationship with

international counterparts, each possessing stable customer groups. Looking

ahead, we look forward to working hand in hand with industry colleagues

worldwide to jointly drive technological iteration and industrial upgrading in

the field of micro winding equipment, providing global customers with

higher-quality products and services, and building a win-win industry

ecosystem.

1. Unmatched

Precision Winding Capability

Stably processes

0.01mm foil wires, breaking through the limitations of traditional enameled

wire winding. Optimized winding tension control addresses the pain point of low

tensile strength and easy breakage of foil wires, achieving yield rates far

above industry standards, on par with the American MCS-101 series micro

winders.

2. Unrivaled

Operational Convenience Outperforming Competitors

Rapid iterative

upgrades simplify the operation process compared to the MCS 101 series. The

touch screen interface paired with a preset micro coil process library allows

beginners to master operation quickly, significantly reducing manual debugging

costs.

3. Full-Scenario

Adaptability for Micro Coils

Covers the

winding needs of various micro coils such as temperature sensors, methane gas

sensors, micro-flow memory coils, and ablation catheters. Supports the

processing of flexible helical coils with slender shafts, enabling one-machine

production of multiple types of micro components.

4. Competitive

Advantage of High Cost-Effectiveness

Process precision rivals international brands, while offering more favorable prices and lower maintenance costs, making it a cost-effective alternative to imported micro coil winding machines.

VI. Customized

Series

Customization ≠ High Price; Customization ≠ High Risk

1. Modular

Combination, Short Customization Cycle

Based on abundant

standard machine cases, core functions such as winding, wire arrangement, and

tension control are modularized. Customer customization requirements can be

quickly implemented through modular combination without starting from scratch

in R&D. The delivery cycle is shortened by over 30% compared to similar

customized machines in the industry.

2. Reuse of

Mature Solutions, Zero Quality Risk

All functional

modules of customized machines have been verified in the market. The core

structures of machines such as 9-slot straight winding motor winding machines,

flexible coupling winding machines, medical titanium plate with trip winding

machines, and high-precision honeycomb coil winding machines are derived from

mature application scenarios. This eliminates the common trial-and-error costs

of customized machines, ensuring quality stability consistent with standard

machines.

3. Custom

Attributes + Standard Costs, Outstanding Cost-Effectiveness

Breaking the

industry pain point of "customization = high price", the modular

design greatly reduces R&D and production marginal costs. It can not only

accurately meet customers' personalized needs but also achieve cost control.

The price is only 10%–15% higher than that of standard machines of the same

specification, far lower than the premium of fully customized machines in the

industry.

4. Full-Scenario

Coverage, Strong Adaptability