Enameled wire production process

Enameled wire process

Enameled wire technological process: pay-off→anneal→paint→baking→cooling→take-up

1. Pay-off On a normally operating enameled machine, most of the operator's energy and physical strength are consumed in the pay-off part. The replacement of the pay-off reel makes the operator pay a lot of labor, and the joints are prone to quality problems when changing the line. An operating failure has occurred. An effective method is to pay off with large capacity.

The key to pay off is to control the tension. When the tension is large, it will not only draw the conductor thin, make the surface of the wire lose its brightness, but also affect many properties of the enameled wire. From the appearance point of view, the enameled wire that is drawn thinner has poor gloss; from the performance point of view, the elongation, resilience, flexibility, and thermal shock of the enameled wire are all affected. If the pay-off tension is too small, the line will easily jump and cause the line to be merged and the line to touch the furnace mouth. When paying off, the most fear is that the half-turn tension is high and the half-turn tension is small. This will not only cause the wires to loosen, break, and be thinned section by section, but also cause large jumps of the wires in the oven, resulting in failures of merging and touching the wires. Pay-off tension should be even and appropriate.

Installing a booster wheel in front of the annealing furnace is very helpful for tension control. The maximum non-extension tension of soft copper wire at room temperature is about 15kg/mm2, the maximum non-extension tension at 400℃ is about 7kg/mm2; the maximum non-extension tension at 460℃ is 4kg/mm2; the maximum non-extension tension at 500℃ The extension tension is 2kg/mm2. In the normal enameled wire coating process, the tension of the enameled wire is significantly less than the non-extension tension, which is required to be controlled at about 50%, and the pay-off tension should be controlled at about 20% of the non-extension tension.

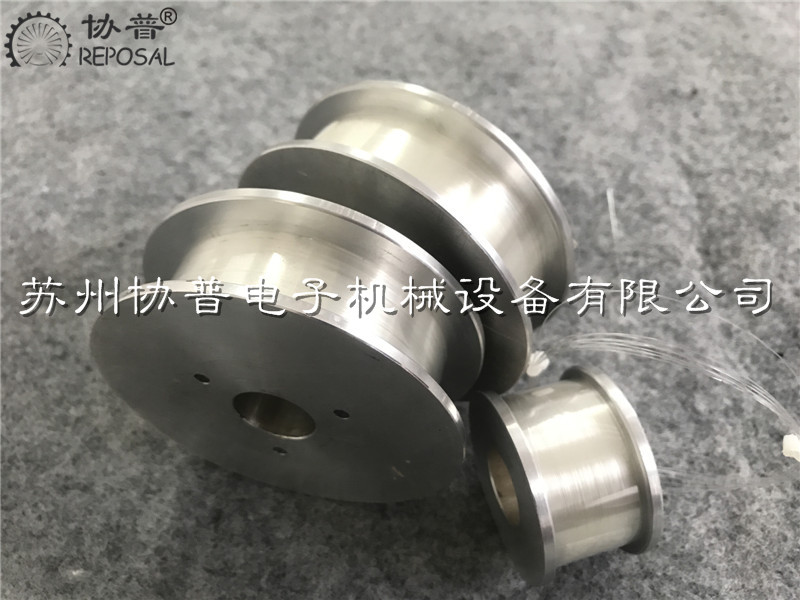

Large-size and large-capacity spools generally use radial rotary pay-off; medium-size wires generally use over-end or brush-type pay-off; fine-size wires generally use brush-type or double-taper-type pay-off. Regardless of the wire payout method, there are strict requirements on the structure and quality of the bare copper wire spool-the surface should be smooth to ensure that the wire is not scratched; ---- 2 on both sides of the shaft core and inside and outside of the side plate —R-angle of 4mm radius to ensure balanced discharge during pay-off; ----After the spool is processed, a dynamic and static balance test must be performed; ——The diameter of the shaft core of the brush pay-off device: the diameter of the side plate Less than 1:1.7; the over-end pay-off requirement is less than 1:1.9, otherwise the line will be broken when the line is set to the shaft core. 2. Annealing The purpose of annealing is to heat the conductor wire hardened by the lattice change during the mold stretching process to a certain temperature to restore the softness required by the process after the molecular lattice rearrangement, while removing the stretching process. Residual lubricant and oil stains on the conductor surface make the wire easy to paint and ensure the quality of the enameled wire. The most important thing is to ensure that the enameled wire has suitable softness and elongation during use as a winding, and at the same time helps to improve the conductivity. The greater the deformation of the conductor, the lower the elongation and the higher the tensile strength.

There are three commonly used methods for annealing copper wire: coil annealing; continuous annealing on wire drawing machine; continuous annealing on enameling machine. Neither of the first two methods can meet the requirements of the enameling process. Coil annealing can only soften the copper wire, but the degreasing is not complete. As the wire becomes soft after annealing, the bend is increased when the wire is laid out. Continuous annealing on the wire drawing machine can achieve the softening of the copper wire and remove the surface grease, but the soft copper wire is wound on the wire reel after annealing to form a lot of bends. Continuous annealing before painting on the enameling machine can not only achieve the purpose of softening and degreasing, but also the annealed wire is straight and directly enters the painting device to coat a uniform paint film. The temperature of the annealing furnace should be determined according to the length of the annealing furnace, copper wire specifications, and line speed. At the same temperature and speed, the longer the annealing furnace, the more fully recovered the conductor lattice.

When the annealing temperature is low, the higher the furnace temperature, the better the elongation, but when the annealing temperature is high, the opposite phenomenon will occur. The higher the temperature, the smaller the elongation, and the surface of the wire loses luster, and is even easy to break. . The temperature of the annealing furnace is too high, which not only affects the service life of the furnace, but also easily burns and breaks when the line is shut down and threaded. The maximum temperature of the annealing furnace is required to be controlled at about 500°C. The two-stage temperature control method is adopted for the furnace, and it is effective to select the temperature control point at the position where the static and dynamic temperature are similar. Copper is easy to oxidize at high temperature. Copper oxide is very loose, and the paint film cannot be firmly attached to the copper wire. Copper oxide has a catalytic effect on the aging of the paint film, and has adverse effects on the flexibility, thermal shock and thermal aging of the enameled wire. .

If the copper wire is not oxidized, it is necessary to keep the copper wire at high temperature from contact with oxygen in the air, so there must be a protective gas. Most annealing furnaces are sealed with water at one end and open at the other end. The water in the water tank of the annealing furnace has three functions: closing the furnace mouth, cooling the wire, and generating steam as a protective gas. Since the water vapor in the annealing tube is very small when driving, the air cannot be removed in time, so a small amount of alcohol solution (1:1) can be poured into the annealing tube. (Be careful not to pour pure alcohol and control the amount used) The water quality in the annealing tank is very important. Impurities in the water will make the wire unclean and affect the paint, and it will not be able to form a smooth paint film. The chlorine content of the used water should be less than 5mg/l, and the conductivity should be less than 50μΩ/cm.

Chloride ions attached to the surface of the copper wire will corrode the copper wire and the paint film after a period of time, and produce black spots on the surface of the wire in the enameled wire paint film. To ensure quality, the sink must be cleaned regularly. The temperature of the water in the sink is also required. High water temperature is beneficial to the generation of water vapor to protect the copper wire during annealing. The wire leaving the water tank is not easy to carry water, but it is not good for the cooling of the wire. Although low water temperature has a cooling effect, there is a large amount of water on the wire, which is not good for painting. Generally, the water temperature of the thick line is lower, and the water temperature of the thin line is higher. When the copper wire makes the water vaporize and splash when it leaves the water surface, it means that the water temperature is too high. Generally, the thick line is controlled at 50~60°C, the middle line is controlled at 60~70°C, and the thin line is controlled at 70~80°C. Because of the high speed of the thin thread, the water-carrying problem is serious, so hot air drying should be used.

3. Painting Painting is the process of coating the enameled wire paint on the metal conductor to form a uniform paint layer with a certain thickness. This is related to several physical phenomena of liquids and painting methods. 1. Physical phenomenon 1) Viscosity When the liquid is flowing, the molecules collide with each other to cause one layer of molecules to move with the other layer of molecules. Due to the mutual force, the latter layer of molecules obstructs the movement of the previous layer of molecules, thus showing The stickiness of the activity is called viscosity. Different painting methods and different wire specifications have different requirements for the viscosity of the paint. The viscosity is mainly related to the molecular weight of the resin. The molecular weight of the resin is large, and the viscosity of the paint is large. It is used to paint thick lines, because the mechanical properties of the paint film obtained with a large molecular weight are better. Low-viscosity ones are used for coating thin wires. The resin's molecular weight is small and it is easy to coat evenly, and the paint film is smoother. 2) Surface tension There are molecules around the molecules inside the liquid, and the gravitational force between these molecules can reach a temporary equilibrium. On the one hand, a layer of molecules on the surface of the liquid is attracted by the gravitational force of the liquid molecules, and its force points to the depth of the liquid. On the other hand, the gas molecules are attracted by the gravitational force of the gas molecules, but the gas molecules are smaller and farther apart than the liquid molecules. Therefore, the molecules on the surface of the liquid are attracted by the gravitational force inside the liquid, causing the surface of the liquid to shrink as much as possible to form a bead shape. In the geometric shape of the same volume, the spherical surface area is the smallest. If the liquid is not affected by other forces, it will always be spherical under the action of surface tension.

According to the surface tension of the paint liquid, the curvature of the uneven surface is different everywhere, and the positive pressure at each point is unbalanced. Before entering the enameling furnace, the thick paint liquid flows to the thin part under the action of surface tension. The paint solution tends to be uniform. This process is called the leveling process. In addition to the leveling effect, the uniformity of the paint film is also affected by the effect of gravity, which is the result of the combined forces of the two. After the painted wire comes out of the felt, there is a rounding process. After the wire is coated with lacquer and felt, the shape of the lacquer is olive-shaped. At this time, under the action of surface tension, the lacquer overcomes the viscosity of the lacquer and turns into a circle in an instant.

The rounding process of the paint solution:

1—painted wire in felt

2—The moment when the felt comes out

3—The paint solution is rounded due to surface tension. If the size of the line is small, the viscosity of the paint is smaller, and the time required for rounding is less; if the size of the line is increased, the viscosity of the paint will also increase. The rounding time is also longer.

In high-viscosity paint, sometimes the surface tension cannot overcome the internal friction of the paint solution, which causes the paint layer to be uneven. When the lacquered wire comes out of the felt, there is still a problem of gravity in the rounding process of the lacquer layer. If the rounding action time is short, the olive-shaped sharp corners will disappear quickly, the effect of gravity will affect it for a short time, and the coating liquid layer on the wire will be relatively uniform. If the rounding time is longer, the sharp corners at both ends will exist for a longer time, and the time of gravity action will be longer. At this time, the paint layer at the sharp corners has a tendency to flow downwards, which will increase the thickness of the paint layer in local areas. The tension forces the lacquer to be drawn into balls and become particles. Since the gravity effect is very prominent when the paint layer is thick, it should not be painted too thick for each paint coating. This is one of the reasons why "thin paint and more paint" is used in the coating of enameled wire. When the thin thread is applied thickly, it will shrink under the action of surface tension to form wavy or bamboo-shaped wool. If there are very fine burrs on the wire, the burrs are not easy to be painted under the action of surface tension, and they are easy to lose and thin, resulting in pinholes in the enameled wire. If the round wire itself is elliptical, the paint layer will be thinner at the two ends of the long axis of the ellipse and thicker at the two ends of the short axis under the effect of the additional pressure when painting, forming a significant unevenness, so the enameled wire is used The out-of-roundness of the round copper wire should meet the requirements.

When bubbles are generated in the paint, the bubbles are the air wrapped in the paint liquid during the agitation and feeding process. Due to the small specific gravity of the air, it rises to the external surface by buoyancy, but the surface tension of the paint liquid makes the air unable to It breaks through the surface and stays in the paint. This paint with air bubbles is applied to the surface of the wire and enters the enameling furnace. After heating, the air expands sharply, and it rushes out of the surface when the surface tension of the paint decreases due to heating. The surface of the enameled wire is not smooth. 3) Wetting phenomenon Mercury droplets shrink into an oval shape on the glass plate, and the water droplets spread out on the glass plate to form a thin layer with a slightly convex center. The former is a wetting phenomenon, and the latter is a non-wetting phenomenon.

The wetting phenomenon is a manifestation of molecular forces. If the gravitational force between the liquid molecules is less than the gravitational force between the liquid and the solid, the liquid will wet the solid, and then the liquid can be evenly coated on the surface of the solid; if the liquid The gravitational force between the molecules is greater than the gravitational force between the liquid and the solid, the liquid cannot wet the solid, and the liquid will shrink into a ball when it is applied to the solid surface. All liquids can wet some solids but not others. The angle between the tangent of the liquid surface and the tangent of the solid surface is called the contact angle. The contact angle is less than 90° for liquid wetting solids, and greater than or equal to 90° for liquids not wetting solids.

If the surface of the copper wire is bright and clean, it can be coated with a layer of paint. If the surface is stained with oil, it will affect the contact angle between the two interfaces of the wire and the paint solution, and the paint solution will change from wetting to non-wetting on the wire. If the copper wire is hard, the irregular arrangement of the surface molecular lattice will have little attraction to the paint, which is not conducive to the wetting of the copper wire by the paint solution. 4) Capillary phenomenon The phenomenon that the liquid that wets the tube wall rises in the tube, and the liquid that does not wet the tube wall drops in the tube is called capillary phenomenon. This is due to the wetting phenomenon and the effect of surface tension. Felt painting is the use of capillary phenomenon. When the liquid wets the tube wall, the liquid rises along the tube wall to form a concave surface, which increases the surface area of the liquid, and the surface tension should minimize the shrinkage of the liquid surface. Under this force, the liquid level tends to be horizontal. The medium liquid rises until the wetting and surface tension pull up and the weight of the rising liquid column in the tube reach equilibrium, the liquid in the tube stops rising. The thinner the capillary, the smaller the specific gravity of the liquid, the smaller the wetted contact angle, the greater the surface tension, the higher the liquid level in the capillary rises, and the more significant the capillary phenomenon.

2. Felt painting method The felt painting method has a simple structure and convenient operation. As long as the felt is clamped on the two sides of the wire with a felt splint, the characteristics of the felt is loose, soft, elastic, and porous to form a die hole and scrape. Remove the excess paint on the wire, absorb, store, transport and make up the paint liquid through capillary phenomenon, and coat the surface of the wire with even paint liquid.

Felt painting method is not suitable for enameled wire paint with too fast solvent volatilization or too high viscosity. Too fast volatilization and too high viscosity will block the pores of the felt and quickly lose its good elasticity and capillary siphoning ability. When using the felt painting method, you must pay attention to: 1) The distance between the felt fixture and the entrance of the oven. Consider the resultant force between the leveling and gravity after painting, the drape of the line and the gravity of the paint liquid when the line travels, (horizontal machine) the distance between the felt and the paint tank is 50-80mm, and the distance between the felt and the furnace mouth 200-250mm is appropriate. 2) The specifications of the felt. When coating coarse specifications, the felt is required to be wide, thick, soft, elastic, and with many pores. The felt is easy to form a relatively large die hole in the paint, and the paint storage is large and the paint is transported quickly. When applying thin threads, it is required to be narrow, thin, dense, and with small pores. You can use cotton wool cloth or undershirt cloth to wrap the felt to form a fine and soft surface, so that the amount of paint is small and even. Painted felt size and density requirements specifications mm width×thickness density g/cm3 specifications mm width×thickness density g/cm3 0.8~2.5 50×16 0.14~0.16 0.1~0.2 30×6 0.25~0.30 0.4~0.8 40×12 0.16 ~0.20 0.05~0.10 25×4 0.30~0.35 0.2~0.4 40×8 0.20~0.25 below 0.05 20×3 0.35~0.40 3) The quality of felt. Painting requires the use of high-quality wool felt with fine and long fibers (the foreign countries have begun to use synthetic fibers with excellent heat resistance and abrasion resistance to replace wool felt). Fat content is less than 0.5%, pH=7, smooth and uniform thickness. 4) Requirements for felt splints. The splint must be finely planed, not rusty, and maintain a flat contact surface with the felt, without bending or deformation. Depending on the wire diameter, prepare splints of different weights. Try to rely on the gravity of the splints to control the tightness of the felt, and avoid compression with elastic screws or springs. The method of self-gravity compaction can make the paint layer of each thread quite consistent. 5) The felt and the paint supply should have a good match. Under the condition that the paint does not change, the paint supply amount can be controlled by adjusting the number of revolutions of the paint roller. The position of the felt and the splint and the wire should be arranged so that the forming die hole is level with the wire, so as to maintain the uniform pressure of the felt on the wire. The horizontal position of the guide wheel of the horizontal enameling machine must be lower than the top of the paint roller, and the top of the paint roller and the center height of the felt interlayer must be at the same level. In order to ensure the thickness and smoothness of the paint film of the enameled wire, it is advisable to use a small cycle for supplying paint. The paint solution is pumped into the large paint box, and the circulating paint is drawn from the large paint box into the small paint tank. As the paint is consumed, the paint in the large paint box continues Supplement the small paint tank to keep the paint in the small paint tank uniform in viscosity and solid content. 6) After a period of use, the capillary pores of the painted felt will be blocked by the copper powder on the copper wire or other impurities in the lacquer. The broken wires, sticking wires or joints in the production will also cause the soft and uniform surface of the felt to be scratched and damaged. , The surface of the wire is damaged by friction with the felt for a long time, and the temperature radiation at the furnace mouth makes the felt hard, so it needs to be replaced regularly. 7) The felt painting method has its inevitable shortcomings. Low utilization rate of frequent replacement work hours, increased waste, and large felt loss