REPOSAL winding machine continuous innovation to consolidate brand value

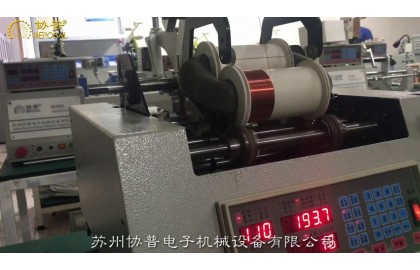

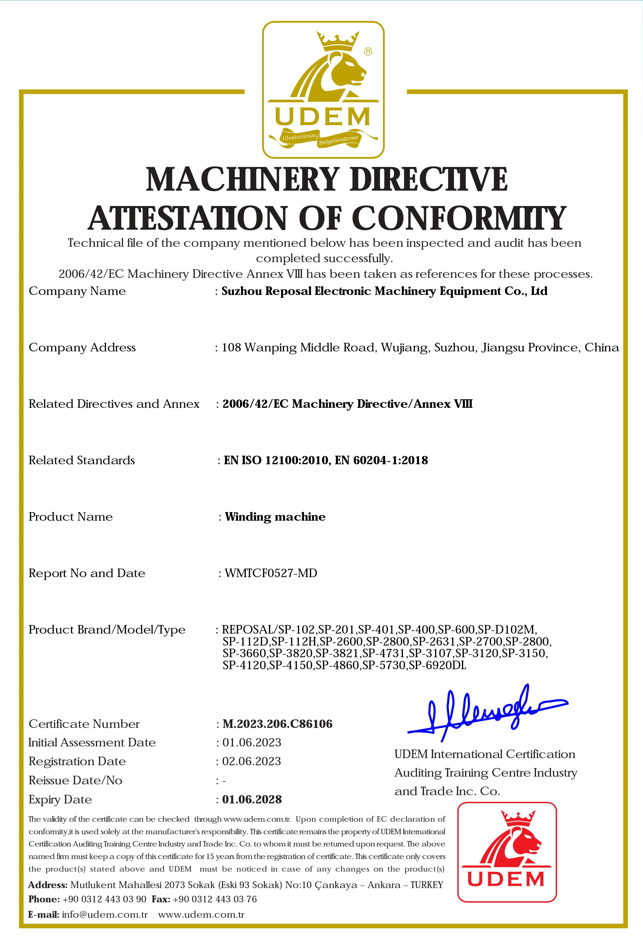

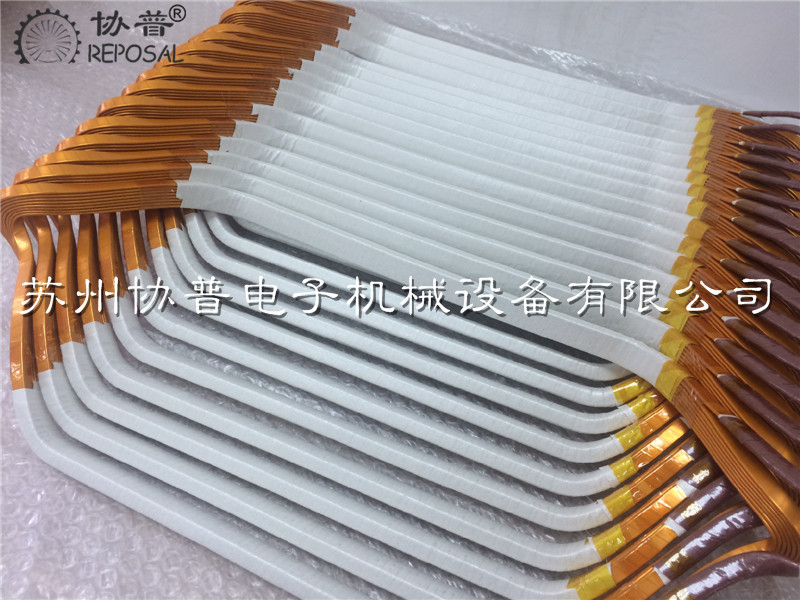

Suzhou REPOSAL Electronic Mechanical Equipment Co., Ltd. is a technology enterprise specializing in R&D and production of winding equipment. For many years, it has insisted on maintaining innovation and researching and developing products with independent intellectual property rights.

For quite a long time, my country's winding machine manufacturing industry generally has the problems of low technology, small scale, free and scattered production, and insufficient technological innovation of most enterprises. Compared with related industries abroad, my country currently has fewer types of winding machines and supporting equipment. The control technology used is relatively backward, and its accuracy and performance are not as good as those of their European and American counterparts. Moreover, the product has low production capacity and poor stability.

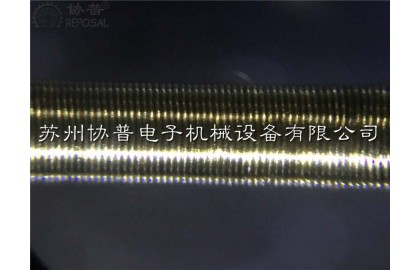

In the face of technical gaps, Suzhou REPOSAL made a detailed market research and took the entire series of precision winding machines and Roche coil winding machines as breakthrough points.It valued cooperation with user companies and not only carefully understood the existing process requirements of customers. And through the company's accumulated technical database for many years, on the premise of no or little increase in costs, it actively provides new ideas and new solutions for customer process upgrades.In a specific single implementation case, this approach has undoubtedly aggravated us The execution cost of the company has reduced the company's profits, but this idea has been implemented and verified for a long time.In fact, our customers have tapped the potential of the coil winding process through our winding machine equipment and become our long-term cooperative customers. We have also accumulated more technical data for our research and development direction and solutions through proactive improvement of individual cases, so as to achieve continuous innovation.

For actively engaged in innovative REPOSAL winding machine, user support is essential. On the one hand, only users actively purchase and use the winding machine we developed can find defects and problems in the application, so as to continuously improve the design scheme, technical route or production process, so as to continuously improve product quality and reliability; on the other hand , Winding machines develop new products for a long time, have a large investment, and have a high risk. Only when they are sold can they recover costs and make profits, and they can also use funds to invest in a new round of research and development, forming a virtuous circle; otherwise, it will easily cause a capital chain Broke, get into trouble or even go bankrupt. In fact, it is not uncommon to see examples of "death on the road" because innovative products cannot be sold; "non-innovation is to wait for death, innovation is to find death", which is not groundless.

From the rise of the automobile industry in Japan and South Korea, it is easier to see the importance of user support. In the 1950s and 1960s, the automobile industries of the two countries started difficultly under the background of Europe and the United States. Their difficulty can be imagined. In the case of no export, it is precisely because of the strong support of the national government and the enthusiastic support of the domestic people that their cars can be increasingly improved, mature, and successfully go to the world. REPOSAL winding machine through the user support, insist on continuous Innovation has also been recognized by more and more customers everywhere.

Of course, companies that are determined to innovate and have high ambitions, in addition to continuous investment in improving independent innovation, also pay attention to production management and quality control. REPOSAL winding machine believes that only excellent quality and reliable performance can win Customer support and trust.