Instructions for use of magnetic damping tensioner for winding machine

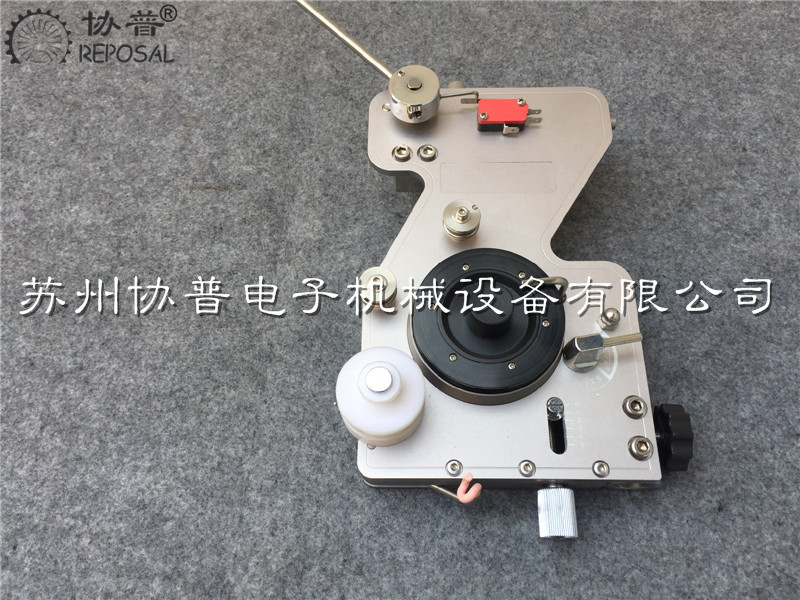

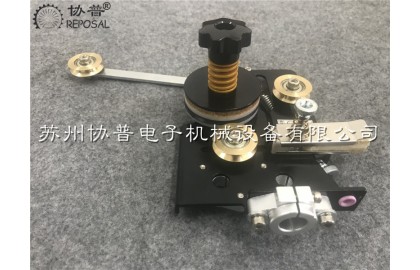

Let's take a look at the thread of the tensioner. From this position, pass the wool felt. If you press here, it will bounce off here, then pass the wheel once, then pass the anti-jumper, and then come back, and then there is Tension. This is a process of going online. Then adjust him in two parts, the first part is the adjustment of the damping wheel, that is to say it is actually a force pulling back. For example, if I now adjust the scale to the state where the tensioner is at its maximum, the pulling force behind it becomes very large, and the pulling force behind it becomes very large.

If I were to turn it down, his stroke would be higher than before. I adjusted it smaller. This seems to be similar to the previous one, and it has risen a little bit. Our ideal situation is horizontal.

How do we adjust this time? We adjusted the pulling force just now, and there is still a rebound force here. We adjusted the rebound force up. This situation is an ideal situation. We now look at it from this side, we are now for example horizontal, and then this position has a scale, 0 is the smallest. Just small.

For example, if we spin from this direction, here is the maximum. The scale of 9 represents the maximum tension of this tensioner, which maximizes the pulling force of the opposite wheel. The wheel pulling force is large, and the carbon fiber rod's rebound force is relatively small, so the carbon fiber rod will come down. We adjusted it back to the position just now, very smooth. For example, if my rebound force is small, it will naturally be level. So it ’s probably clear to see here, so the adjustment of the tensioner is actually a balance between a pulling force and a rebound force