Transformer winding machine

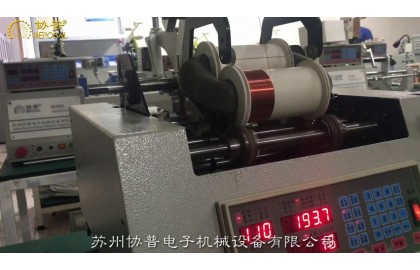

Transformer winding machine:

This model is generally used to wind small-size current transformers. The characteristics of small-size current transformers are generally wire diameter of enameled wire between 0.11-0.19mm, and the number of turns is large.

It requires accurate turns and fast winding speed.

Related Post

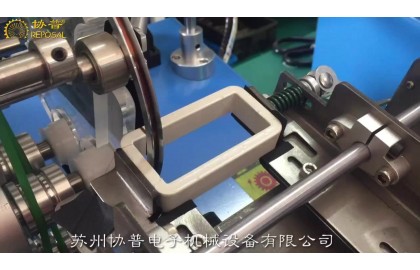

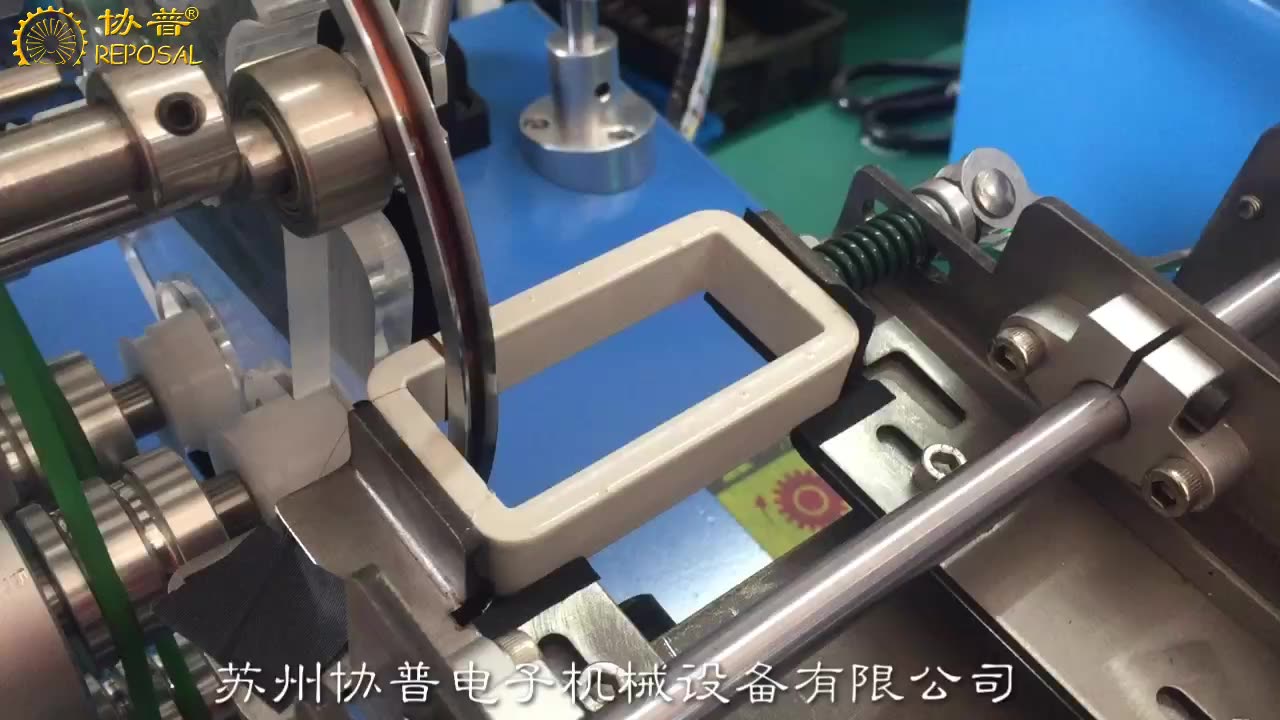

Enclosed rectangular transformer winding machine-thin wire reciprocating

Enclosed rectangular transformer coil with a thin diameter of 0.12mm, which requires fast winding speed and convenient product loading and unloading.

R-type transformer winding machine

The cross section of an R-type transformer is like the letter R, so it is called an R-type transformer. The application of R-type transformers in high-power electrical appliances can reduce inrush current. R-type transformers are one of the dry-type transformers. The iron core is made of continuous high-quality oriented cold-rolled silicon steel strip from thin to thick, and then from thick to thin. The final cross-section is close to a circle, and the shape is an uncut closed rectangle, and then passes through a special R-shaped transformer The winding machine winds the coarse secondary on its PBT skeleton. Therefore, the transformer thus manufactured has no noise, low magnetic leakage, low no-load current, low iron loss, and high efficiency; and because the coil is cylindrical, the length of the coil copper wire wound by the R-type transformer winding machine short, so , Low internal resistance, low copper consumption, low temperature rise, low over-carrier motion, and better explosive force than toroidal transformers; in addition, the primary and secondary coils are separately wound with flame-retardant PBT engineering plastic skeletons, thus high electrical strength , Good flame retardancy.

However, the manufacturing process is more complicated. The second is the winding of the coil. Because it is wound in a closed iron core, the PBT is composed of two parts, and then the R-type transformer winding machine drives the PBT skeleton to wind, and the winding accuracy is affected. A certain influence, one is the shape of its iron core, because its expanded shape is a spinning cone, so its mold and material utilization are relatively low.

With the development of R-type transformer winding machines, the reduction of manufacturing costs, and the improvement of quality stability, R-type transformers are being favored by more and more electronics industries with their novel and unique structure and excellent electromagnetic performance. Especially suitable for medical equipment, display equipment, audio equipment, office equipment.

U-shaped core winding machine

Transformer coil winding machine

Stable, high-speed and safe U-shaped core coil winding machine

The U-shaped coil winding machine is suitable for the winding of the bottom edge of the U-shaped core.Usually, the center of the U-shaped core is difficult to coincide with the rotation axis of the winding machine, resulting in a large vibration of the winding machine. , Affecting efficiency.

This type of winding machine developed by our company does not rotate the U-shaped iron core, only reciprocates, and rotates around the product to reduce vibration and improve efficiency.

With the optimized clamping method, it only takes 2 seconds to complete the clamping.

Therefore, the rotating parts of this type of machine have a large diameter and a high speed.There are similar machines on the market, and the larger ones do not have a protective cover. Safety accidents often occur.This machine of the company has a protective cover design.

Transformer winding crepe paper | Transformer winding crepe paper | Transformer winding crepe paper

Transformer insulating crepe paper has good mechanical strength, high withstand voltage strength, wrinkles on the surface, and a certain degree of toughness. Moreover, it is easy to cut. After the transformer is wound and formed, it still maintains a certain strength in the oil immersion of the rear tooling. This feature can very well protect the enameled wire of the transformer from being squeezed and broken, that is, it meets the insulation requirements. It also meets the mechanical performance requirements.

Therefore, it is widely used for transformer insulation. Generally used in transformers, but less used in transformers, because the core structure of transformers is annular, because the surface of the insulating crepe paper has wrinkles and friction is large, so the annular wrapping machine is used. Winding is more difficult, so in general, if crepe paper is required for the transformer coil, manual winding is used. We have successfully overcome this problem by improving the details.

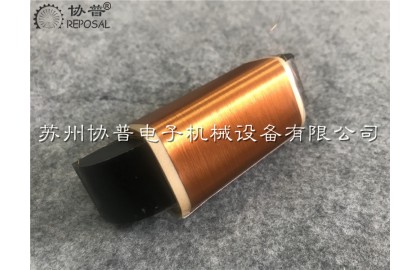

Micro toroidal coil winding

Before winding:

Outer diameter 7.5mm

Inner diameter 4mm

Height 2.3mm

Enameled wire diameter: 0.17mm

80 laps.

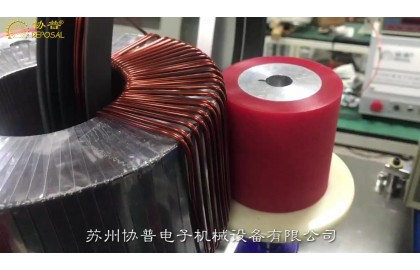

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

Research and development background and characteristics of precision current transformer winding machine

Research and development background and characteristics of precision current transformer winding machine

The precision of coil in current transformer is very important, because it directly affects the accuracy of current measurement and the reliable operation of power system. The specific importance of coil accuracy is reflected in the following aspects.

Electrical energy metering: In a power system, accurate measurement of current is the key to calculating energy consumption. If the coil in the current transformer is not accurate, it will lead to an error in the measurement of electrical energy, which can lead to a miscalculation of energy costs, with possible financial implications for both the utility and the consumer.

Fault detection: The current transformer is used to monitor the current level to detect abnormal conditions in the power system, such as short circuit and overload. If the accuracy of the coil is not high, it may lead to false positives or neglect of potential faults, which affects the reliability of the power system.

Overcurrent protection: Current transformers play a key role in overcurrent protection devices, detecting overcurrent events and triggering circuit breakers or other protective devices. The accuracy of the coil directly affects whether the overcurrent can be accurately detected to ensure the safety of the power system.

Load management: The load management of a power system requires accurate measurement of current in order to make reasonable load distribution and adjustment. If the precision of the coil is not high, it may lead to unbalanced load distribution, affecting the efficiency and stability of the power system.

Automated control: In modern power systems, automated control systems rely on accurate current measurement data for real-time adjustment and control. The precision of the coil is critical to the response speed and performance of the system.

Waveform analysis: Current transformers are also used for power quality analysis, including harmonic analysis. The precision of the coil determines the accurate analysis of the current waveform, which helps to solve the power quality problem.

What are the application scope and types of winding machines?

Winding machine: As the name implies, a winding machine is a machine that winds a linear object onto a specific workpiece.

The scope of application of the winding machine:

Most electrical products need to use enameled copper wire (referred to as enameled wire) to be wound into inductance coils, which requires a winding machine.

For example: various motors, fluorescent lamp ballasts, transformers of various sizes, televisions. The mid-periphery and inductive coils used in the radio, the line output transformer (high-voltage package), the high-voltage coil on the electronic igniter, the mosquito killer, the loudspeaker, the earphone, the voice coil of the microphone, the various electric welding machines, etc. can not be cited one by one. All coils need to be wound with a winding machine.

In the textile industry, cotton yarns, man-made fiber yarns, etc. are used to wind all kinds of yarn balls and frays suitable for textile machines. These require a winding machine to wind.

Type of winding machine:

Commonly used wire winding machines are mostly enameled copper wire (winding inductance coils for electronic and electrical products), textile wire (winding yarn frays and coils for textile machines), and winding electric heating appliances. Electric heating wires and solder wires, wires, cables, etc.

There are many types of winding machines, which can be classified into general-purpose and special-purpose types according to their uses;

Instructions for use of side-sliding transformer winding machine

Instructions for use of side-sliding transformer winding machine