Classification and difference of transformer winding machine

Classification and differences of common transformer winding machines

Choosing the right winding machine is the key to the production of coils. There are many types of winding machines as basic equipment. This article mainly takes transformer winding machines as an example, and talks about its classification and differences, generally according to the voltage level or capacity of the transformer. Divided, the common ones are ordinary CNC winding machines, automatic winding machines, foil winding machines, vertical winding machines, and so on.

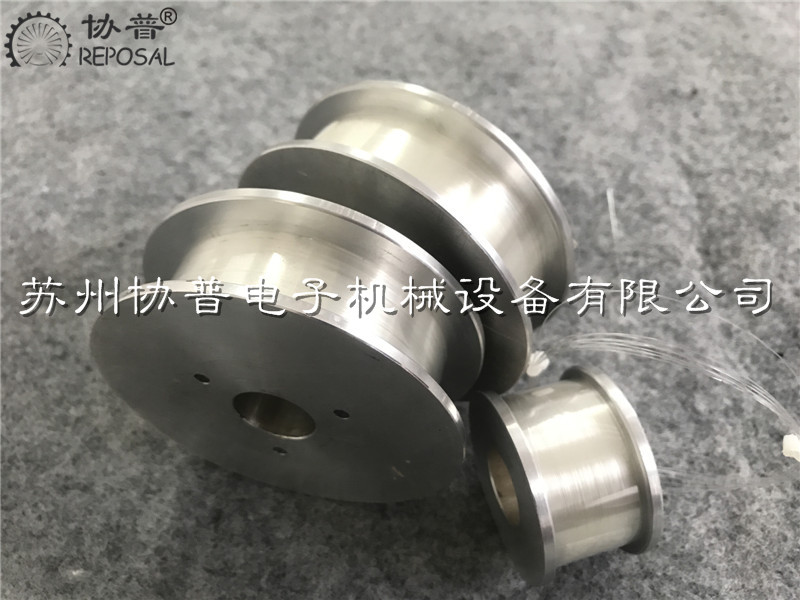

1. Ordinary CNC winding machine

Ordinary CNC winding machines are our common winding equipment. The product line of this series covers a wide range of medium and small models as well as heavy and large models. The control system generally uses single-chip microcomputer circuits, due to its low price, stable performance, and easy maintenance. Features, widely used in transformer manufacturers.

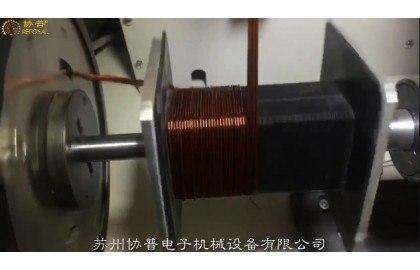

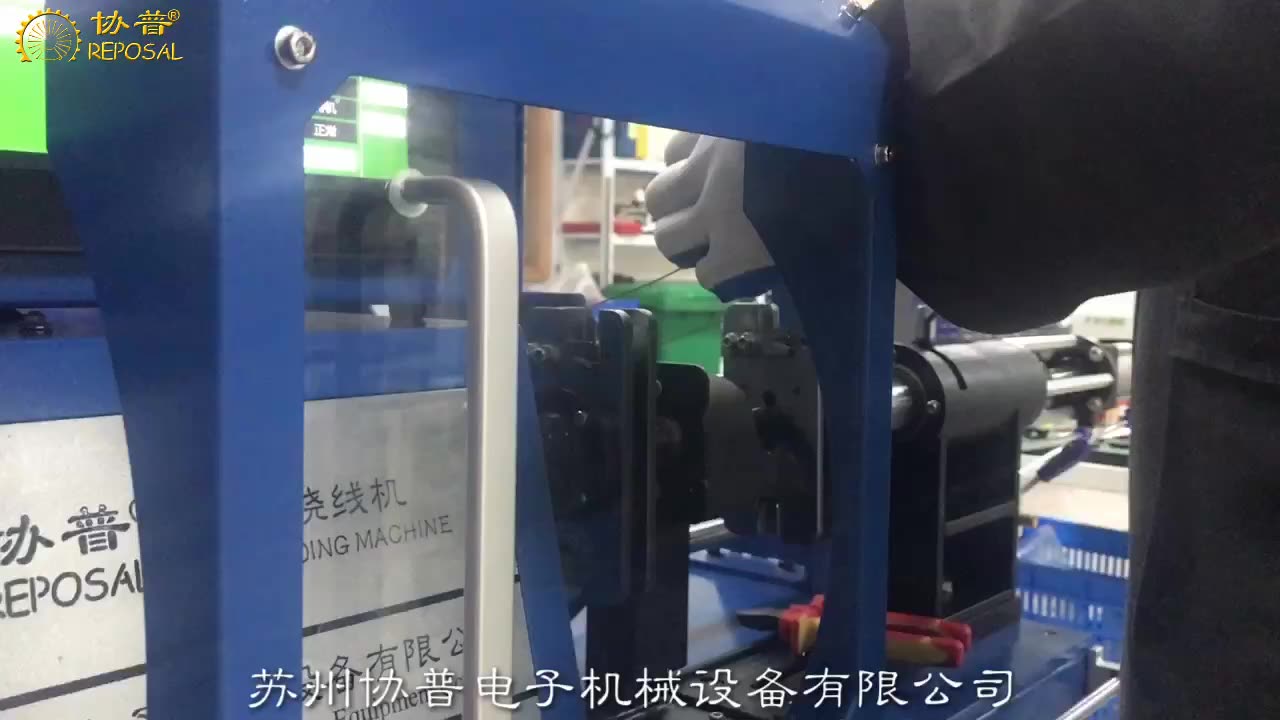

2. Automatic precision winding machine

The emergence of automatic precision winding machines has greatly reduced the winding intensity of operators. Our common automatic winding machines generally use cnc controllers, and high-end models use plc and precision servo systems to meet the needs of modern electricity. The speed of the winding machine is getting higher and higher, and the processing capacity is also improving. The supporting wire tensioning mechanism is used to make the wound coil beautiful and neat.

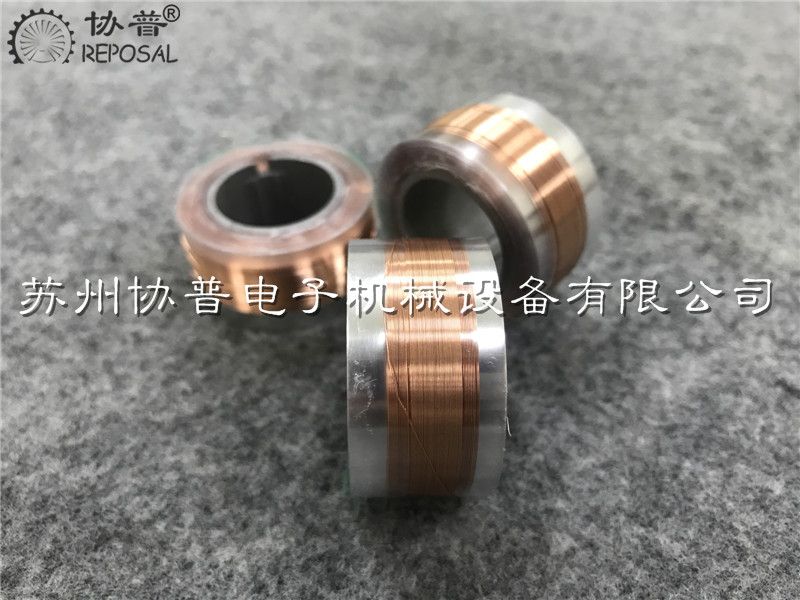

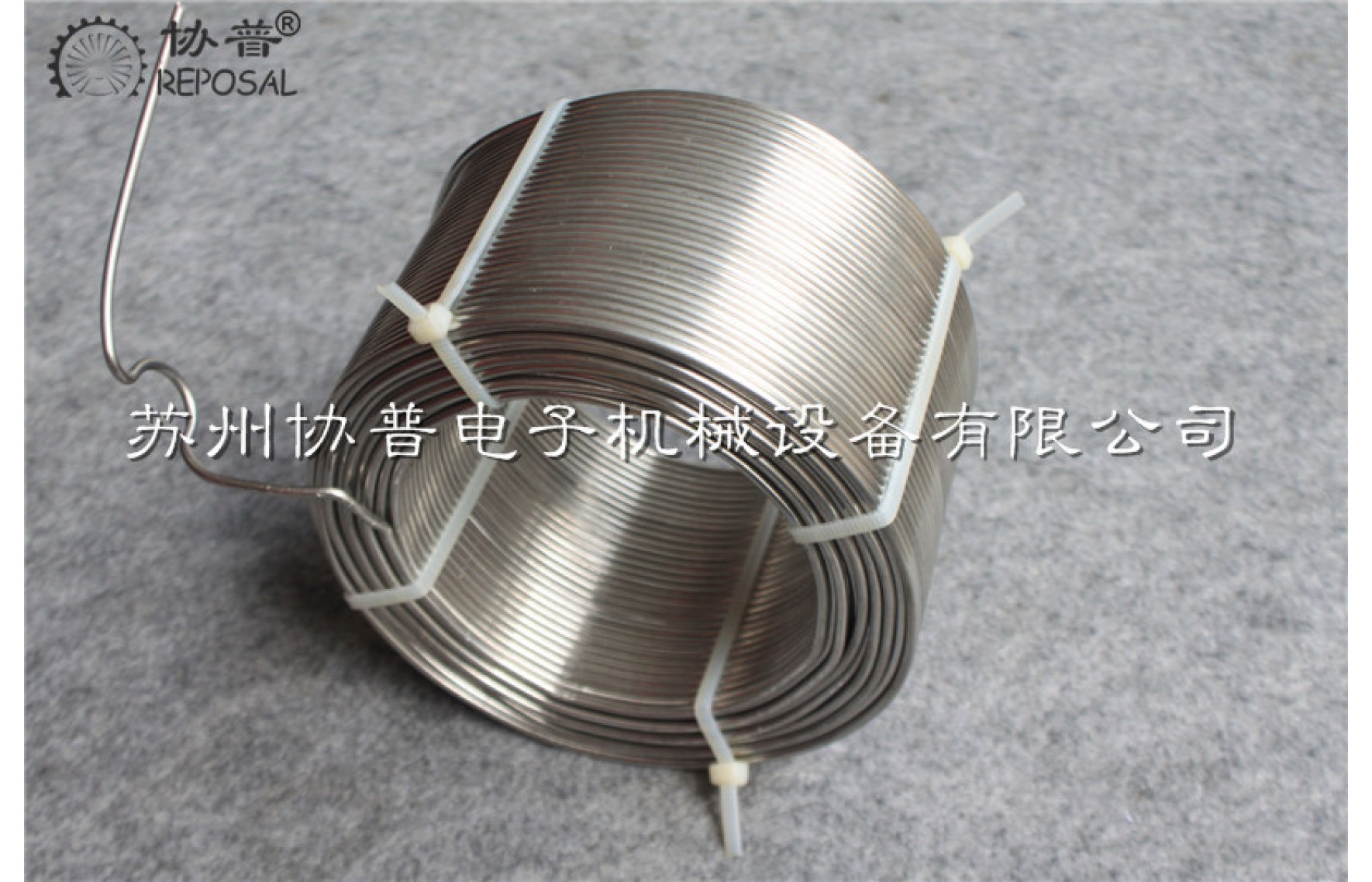

3, Coil winding machine

Coil winding machine is mainly used to wind foil coils. Its structure and function are much more complicated than ordinary winding machines. Tension control and foil strip correction are the key technologies of foil winding machines. At present, the domestically produced control technology There is still a certain gap between Shanghai and imported equipment. Domestic manufacturers have invested and paid a lot of attention in this area, and technical problems are being solved gradually.

4, vertical winding machine

It may not be very common for vertical winding machines. It belongs to special equipment. In large transformers, the winding of high-voltage coils generally uses vertical winding machines, and low-voltage spiral coils also use vertical winding machines. The working principle and processing range are completely different from our common parallel winding machine. At present, the vertical winding machine is further developed to large-scale, and the load-bearing capacity is also continuously improved, which makes the winding production reach a new level.

5, three-dimensional winding iron core winding machine

The three-dimensional iron core three-dimensional winding machine has a high degree of automation. You only need to input the number of gear teeth of the winding coil on the operation screen to directly display the number of winding turns, which avoids the traditional calculation of the number of turns and the error of the number of turns. The equipment realizes the working mode of the winding staff sitting and winding the coil, which greatly reduces the labor intensity. At the same time, the three-dimensional winding machine has reversible and power-off memory functions, simple and reliable operation, high efficiency, and applicable scope. It is a new generation of intelligent three-dimensional three-dimensional winding iron core coil winding equipment.