Solenoid valve winding machine|Solenoid valve coil precision winding machine|Precision winding machine

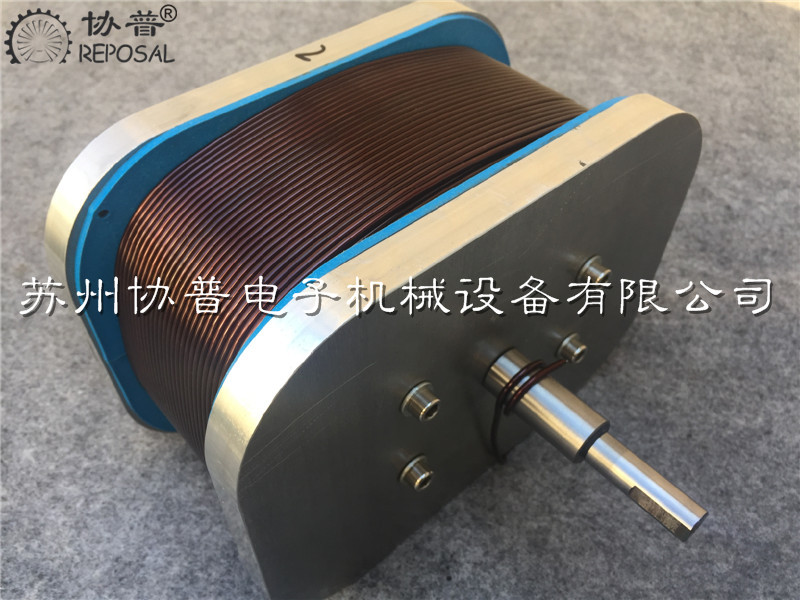

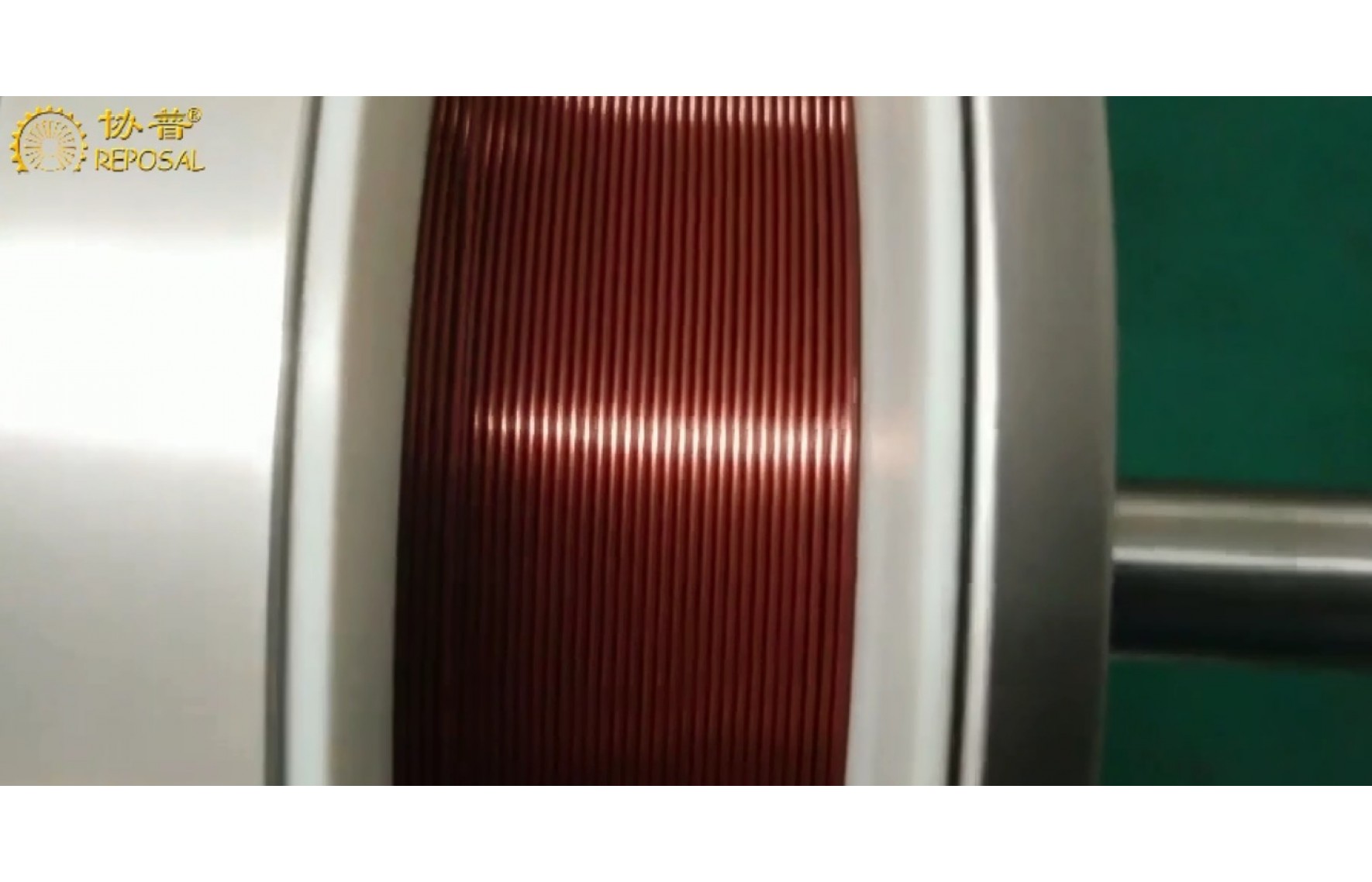

For precision electromagnetic coils, there are usually many turns, which require neat arrangement, and the process design is also divided into two types with and without skeleton.

For precision electromagnetic coils, there are usually many turns, which require neat arrangement, and the process design is also divided into two types with and without skeleton.

For frameless coils, steel molds are required to form.Relatively speaking, the precision of steel winding molds is better controlled.

Under the existing solenoid valve winding machine processing technology, it is not difficult to achieve a size of 0.01mm on both sides of the steel winding mold, and the parallelism on both sides is 0.01

mm is also not difficult. However, if there is no wire frame mold steel wire winding mold, there will be two new problems, one is forming, the winding is completed

After the final removal, there is no skeleton.To prevent the coil from being scattered, it is necessary to use an alcohol fuse or a hot fuse. These two materials

Compared with the ordinary wire, the cost is not small. The second problem is demolding, a thicker one, and more windings

It's quite laborious to remove the coil from a steel mold, it's not like a coil with a small coin, and

What's more, this winding process itself has viscous materials that are melted or hot melted.

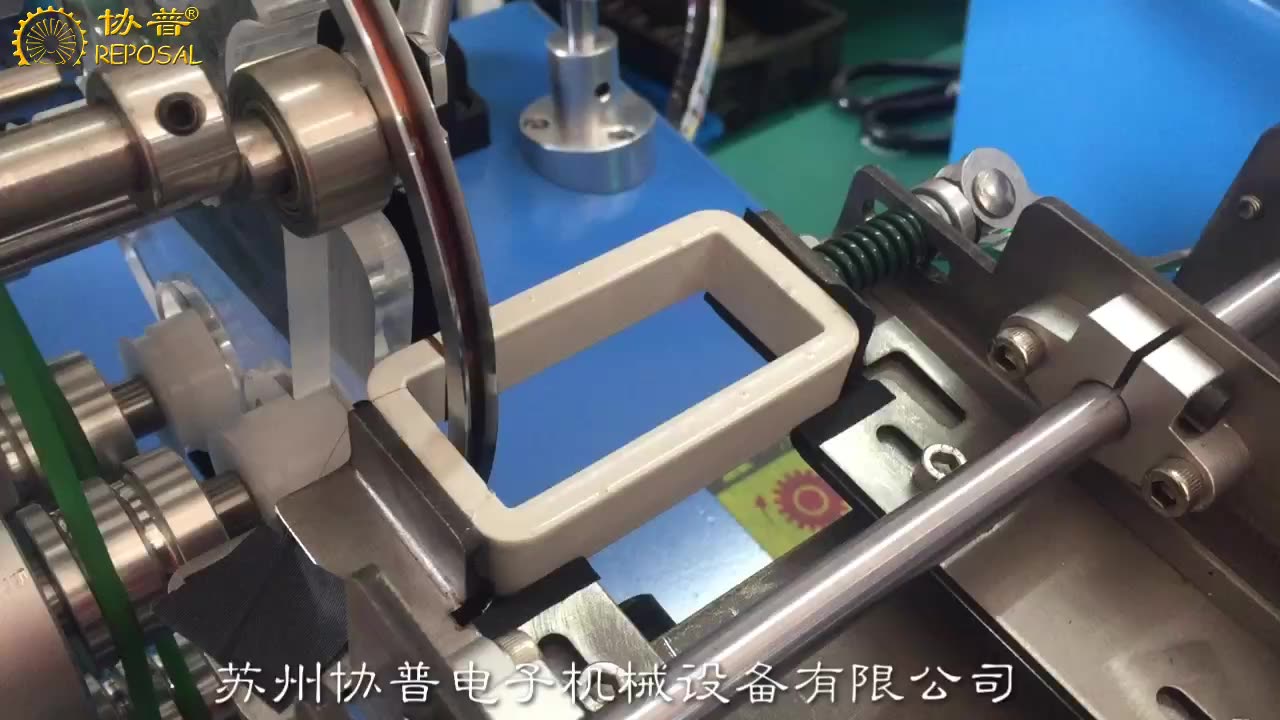

So people also use the second solenoid valve winding machine process, a precision electromagnetic coil with a skeleton.Similarly, this is not a very good process route.

The skeleton is formed by an injection mold, and there are inevitably some problems with injection products, such as deformation, shrinkage, dimensional consistency, etc.

However, the advantages of this solenoid valve winding machine are also obvious, that is, it is easy to demold and form. It is only because of the poor consistency of the size of the skeleton.

Higher requirements are put forward, the key point is that wire, skeleton structure, skeleton mold, winding tooling, winding machine, every link

Will affect the quality of the winding, in this case, according to our own advantages, we provide a complete service according to customer needs

Including skeleton design, mold structure design, tooling design, and winding machine. In the past successful cooperation, this way of service

Great advantages.