Tension control of precision rectangular coil winding machine

This article introduces the test of designing tension control system to minimize the change of tension. Perform theoretical analysis on simulation. The simulation results show that the tension of the enameled wire is frequently fluctuated due to the length change caused by the speed change. The model's tension sensor verifies the prediction. The key to successful design is to eliminate changes in tension. We added a tension system that includes a high-speed cylinder to replace the traditional wool felt and spring mechanism. The simulation results showed that the new prototype system almost doubled the winding speed and the ability to withstand tension fluctuations.

Keywords: tension control, winding machine, rectangular coil, precision winding machine. One. introduction

Countless transformers are produced every year. Together with power plants, substations and power lines, distribution transformers provide electricity for businesses and residential buildings across the country. Transformer manufacturing involves the production of winding coils. These coils are usually made of an insulating paper layer sandwiched between a pair of copper wires. They are usually round or rectangular.

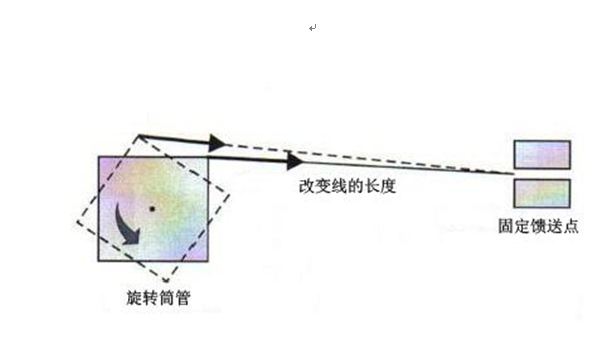

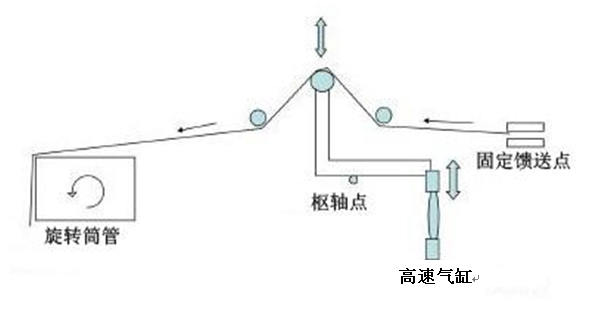

A consistent tension must be maintained on the coil windings. The shape of the coil has a major influence on the tension applied by the tension. For a circular coil, the tension does not change significantly, but a rectangular coil is different. As a rectangular coil, the tension changes sharply with the position of the drop point. As shown in the figure, this change in speed is caused by the changing length of the line. In the case of a round coil, this is not a problem, because the contact points of the wires on the coil are fixed.

Figure 1: Changes in speed lead to changes in winding length

The wire and different spindle load tensions on the machine result in different results, resulting in excessive force changes and mechanical vibration. This in turn may cause the enameled wire of the changing coil to cross. When these problems occur, it takes time to correct them at the bypass site. Will greatly affect the production capacity of the coil factory. The common tension device on the market today, which is suitable for thicker enameled wire packages, runs between about 5 m/s and 30 m/s. Our usual winding speed exceeds 10 m/s, and the company's goal is to achieve a speed of at least 20 m/s for 0.45 mm to 4 mm wire.

This paper further investigates the problem of tension fluctuations, and obtains a consistent tension relationship in high-speed winding rectangular coils. In the following part of the problem is explained, the existing available technology is reviewed.

two. background

The existing winding system uses wool felt, friction wheels, and rebound bars. The tension control is realized by fixing or loosening the elastic force of the wool felt and the spring.

Wool felt is one of the simplest and most commonly used methods of thread tension control.

The enameled wire passes through the wool felt, so pressing the wool felt can also change the tension of the enameled wire. In actual operation, the size of the tension depends on the sliding friction between the wool felt and the enameled wire. When the pressure of the wool felt is changed, the tension of the enameled wire will appear intuitively. Its advantages are: simple, readily available, cheap, and adaptable to any operating speed. The disadvantages are also obvious. The wool felt wears out very quickly, leading to the loss of situational pressure, and must be replaced and adjusted frequently.

three. Model recognition

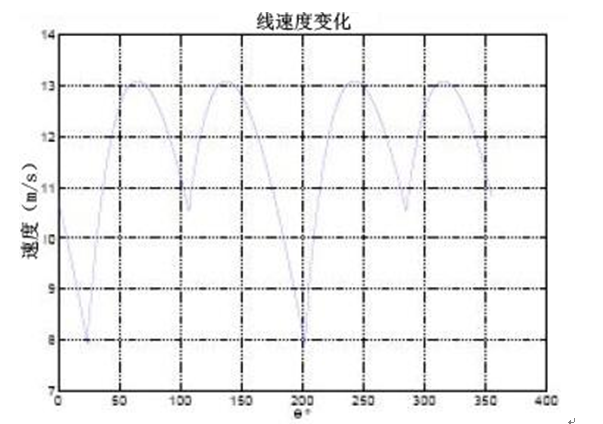

The tension device through which the wire passes through the spool, passes through the feeder hole of the machine, and is loaded with a rectangular coil. The ideal operating speed is 1000 revolutions per minute. A line speed of 10-30 m/s is given, so the specific speed actually depends on the size of the coil at a particular moment. Figure 3 shows the change in linear velocity of the enameled wire when wound by a rectangular coil.

Figure 3: Changes in linear velocity

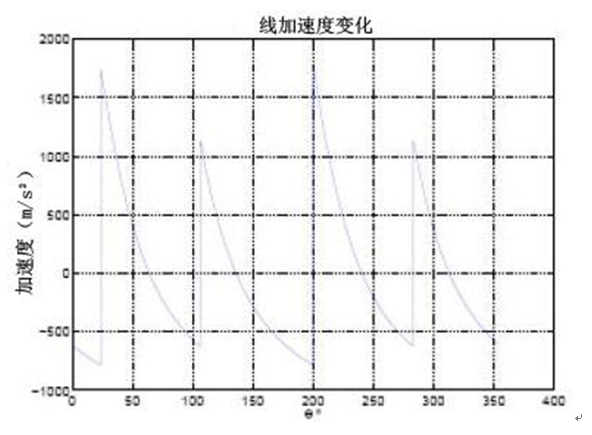

Figure 4 shows the change in linear acceleration, which can also be seen through the line or graph speed curve.

Figure 4: Linear acceleration changes

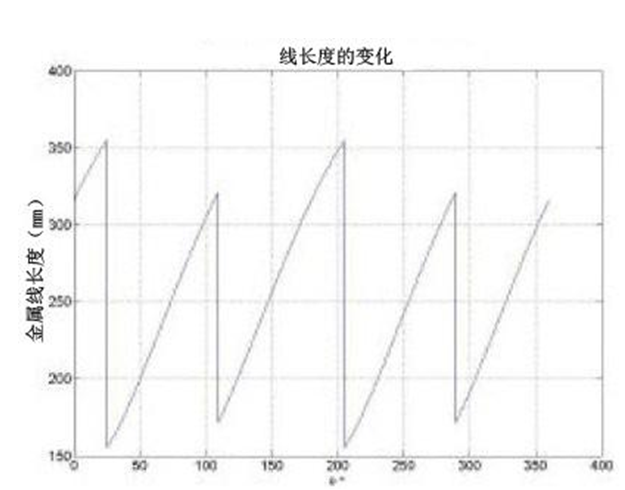

The change of the line path length, from the fixed feeder point to the entanglement point, as shown in Figure 5.

Variation of wire length

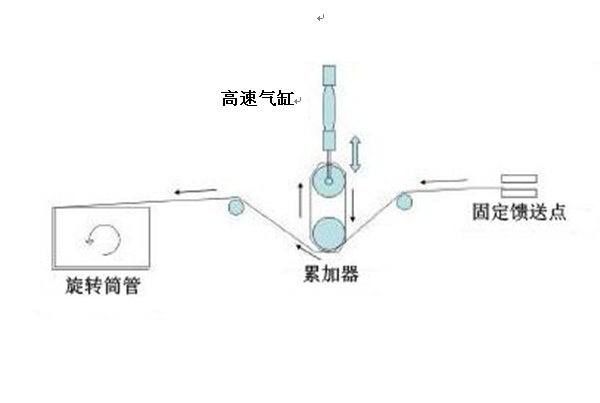

four. Prototype system design

The system in the figure below integrates a high-speed cylinder. The high-speed cylinder operates under air pressure. The pre-pressure depends on the air pressure. It has a very fast response, similar to a highly dynamic spring. The follow-up action of the high-speed cylinder releases and adjusts the tension of the enameled wire. This integrated setting adapts to a series of tension changes required by the enameled wire.

High-speed cylinder tension system

Fives. in conclusion

Rectangular coil is an important part of distribution transformer. Due to the coil shape, the enameled wire tension of the coil fluctuates. These fluctuations cause the enameled wire to be damaged, the enameled wire is not neatly arranged, the size of the coil is inconsistent, the excess machine wear, and the winding speed is limited, and the inter-turn withstand voltage and temperature resistance parameters of the coil are reduced. From our research on this tension system, we found that this result is the most suitable choice for thicker enameled wire winding technology.

The video below shows the precision rectangular coil winding process, which verifies the stable results after the optimization of the tension system in the article.