Instructions for use of side-sliding transformer winding machine

Instructions for use of side-sliding transformer winding machine

Related Post

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Precise winding of self-adhesive coil with skeleton

As shown in the figure below, it is a sensor coil used in the medical industry. The skeleton is made of aluminum. The diameter of the enameled wire is 0.1mm. The customer requires the arrangement to be neat and free of winding defects. The company has carefully evaluated the specific requirements of the customer, because the winding process and winding are considered. After the completion of the structure, the self-adhesive enameled wire process was adopted, and the self-adhesive coil winding machine was further optimized. The project was successfully completed. At the same time, some experience was summarized and shared with the public during the process.

In recent years, due to self-adhesive support, self-adhesive coils do not need to be dipped in the later stage, which is convenient for industrialization. They have been widely used in deflection coils of precision instruments, combined coils in micro motors, and micro coils in sensors.

U-shaped core winding machine

Transformer coil winding machine

Stable, high-speed and safe U-shaped core coil winding machine

The U-shaped coil winding machine is suitable for the winding of the bottom edge of the U-shaped core.Usually, the center of the U-shaped core is difficult to coincide with the rotation axis of the winding machine, resulting in a large vibration of the winding machine. , Affecting efficiency.

This type of winding machine developed by our company does not rotate the U-shaped iron core, only reciprocates, and rotates around the product to reduce vibration and improve efficiency.

With the optimized clamping method, it only takes 2 seconds to complete the clamping.

Therefore, the rotating parts of this type of machine have a large diameter and a high speed.There are similar machines on the market, and the larger ones do not have a protective cover. Safety accidents often occur.This machine of the company has a protective cover design.

Transformer winding machine

Transformer winding machine:

Similar to transformers, current transformers also work according to the principle of electromagnetic induction. The transformer transforms voltage and the current transformer transforms current. The current transformer is connected to the winding of the measured current (the number of turns is N1), called the primary winding (or primary winding, primary winding); the winding connected to the measuring instrument (the number of turns is N2) is called the secondary winding (or secondary side) Winding, secondary winding).

This ring current transformer winding machine is generally used to wind small size current transformers. The characteristics of small size current transformers are generally wire diameter of enameled wire between 0.11-0.19mm, and the number of turns is large.

It requires accurate turns and fast winding speed.

REPOSAL this machine is fast and stable, and the speed reaches 1400RPM. Because it is stable, it can realize the operation of multiple ring current transformer winding machines by one person.

Fiber Optic Gyro Winding Machine-REPOSAL® Winding Machine Official Website

Compared with mechanical gyroscopes, fiber optic gyroscopes have no moving parts, impact resistance, high sensitivity, and long life. Therefore, fiber optic gyroscopes are widely used in high-precision and high-speed positioning scenarios and will gradually replace electromechanical gyroscopes.

The basic components of the fiber optic gyroscope are the optical path and the circuit, and the fiber is the core component of the gyroscope. The fiber winding machine for preparing high-precision fiber coils has also become the key point of the gyroscope.

However, due to the blockade of its related technologies, the fiber optic gyro winding machine has always been a key technology insurmountable. REPOSAL® Electronic Machinery Co., Ltd. actively develops fiber optic gyro winding machines in response to market demand.

Through continuous research and improvement, we automate the winding process of the fiber optic gyroscope, and compare and analyze the winding methods of various fiber coils. We have obtained that the tension control and the accuracy of the winding during the fiber winding process affect the structure of the wound fiber coil. The key factor.

By optimizing the aforementioned tension control factors and winding accuracy algorithm, the effective and stable control of reasonable tension, the effective and reliable high-precision winding control, the memory of all process parameters, and the convenience of control, a new generation of optical fiber winding machine was developed and put into production .

With the practical application of research and development results, we will continue to improve and produce high-reliability and high-efficiency fiber optic gyro winding machines.

REPOSAL's successfully developed precision flexible Roche coil winding machine

Precision Flexible Roche Coil Winding Machine is a special equipment for winding precision flexible Roche coils. With the actual project as the background, Xiepu successfully developed a precision flexible Rogowski coil winding machine by decomposing the flexible Rogowski coil winding process.

The precision flexible Roche coil winding machine does not belong to the ranks of general numerical control equipment, but a special non-standard equipment. For this type of equipment, it is mainly reflected in a special purpose. Since the special purpose means that the market demand is not large, it is indispensable. For equipment manufacturers, the development of such special equipment is not favored, and cost control is very difficult.

In addition, the current domestic manufacturers of flexible Roche coils have limited demand for equipment. At the same time, if you want to control the pitch accuracy and alignment, the equipment research and development costs are relatively high, and the market risk is large. At the same time, for equipment users, their corresponding The supporting equipment and instruments are a large investment.

Micro toroidal coil winding

Before winding:

Outer diameter 7.5mm

Inner diameter 4mm

Height 2.3mm

Enameled wire diameter: 0.17mm

80 laps.

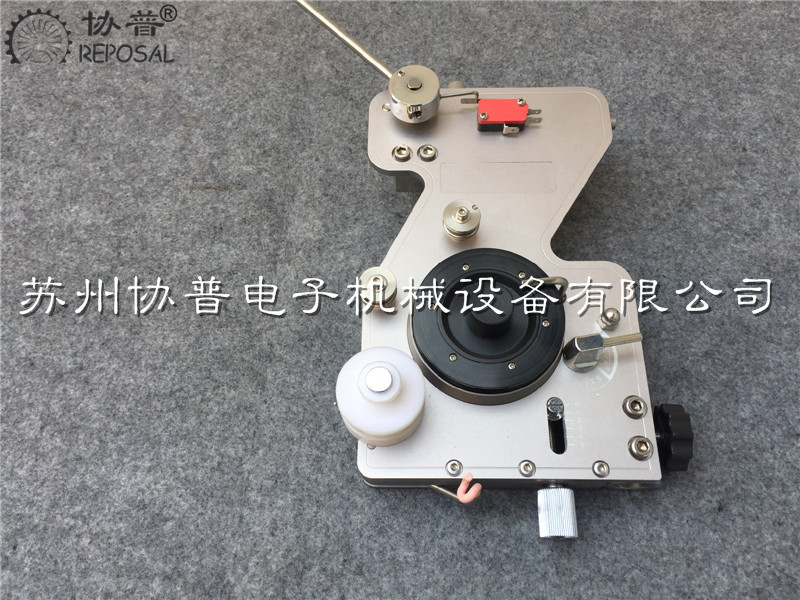

Mechanical Tensioner Guide

Let's now look at the tensioner, a threading process. First, the enameled wire passes through the ceramic ring at the bottom of the tensioner, and then passes through the wool felt above it. The clamping degree of the wool felt can be adjusted by passing the knob on the other side of the tensioner.

Then go through the anti-jumper, and then go over the damping wheel on the tensioner once again, then pass through an anti-jumper again, and then pass through the guide wheel on the fishing rod, this is the threading process.

Then how do we adjust to a more appropriate tension?

Let's take a look at the first one now. This handle is a tension switch. When the tension switch hits the top, the damping wheel doesn't work. When it is turned, it becomes very light. When the tension switch hits the bottom, the tensioner starts to work.

If we want to increase the tension, we adjust the knob under the bottom of the tensioner, there is a scale in this position. Through this, adjust the damping size of the damping wheel on the tensioner.

Then the handle at this position is used to adjust the back tension, which is the force of the fishing rod to bounce back. The general principle of our adjustment is that during the winding process, the fishing rod will not become weak under the interaction of the damping wheel. Sagging down, it will not be too strong and only a good swing requires a relatively large swing range, so that it can buffer and at the same time play a role in tensioning the enameled wire.