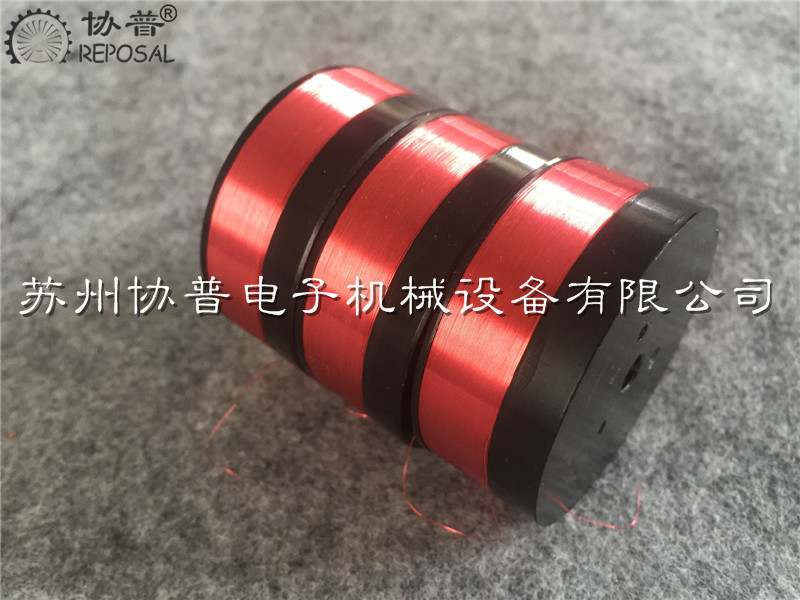

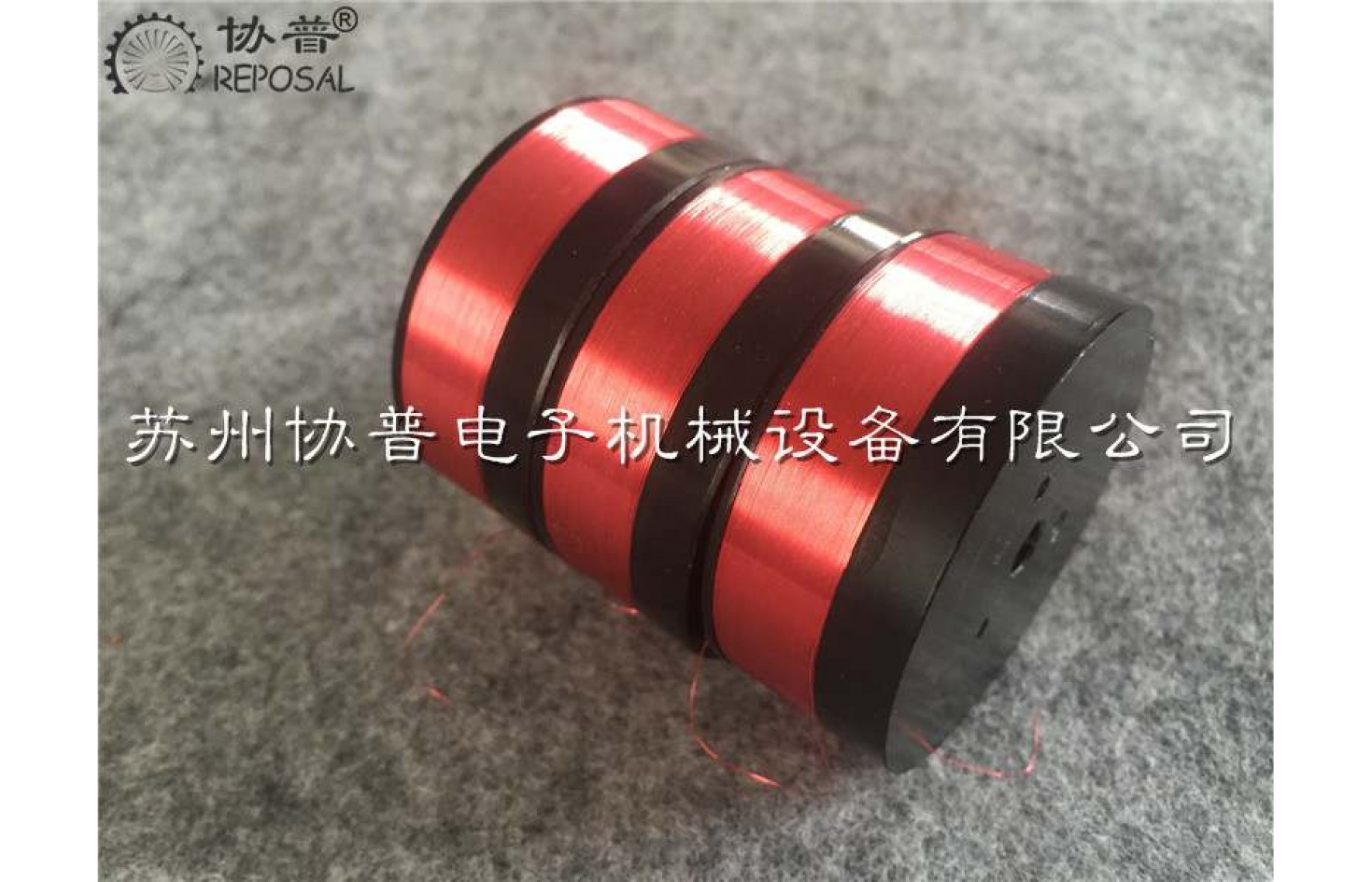

Precise winding of self-adhesive coil with skeleton

As shown in the figure below, it is a sensor coil used in the medical industry. The skeleton is made of aluminum. The diameter of the enameled wire is 0.1mm. The customer requires the arrangement to be neat and free of winding defects. The company has carefully evaluated the specific requirements of the customer, because the winding process and winding are considered. After the completion of the structure, the self-adhesive enameled wire process was adopted, and the self-adhesive coil winding machine was further optimized. The project was successfully completed. At the same time, some experience was summarized and shared with the public during the process.

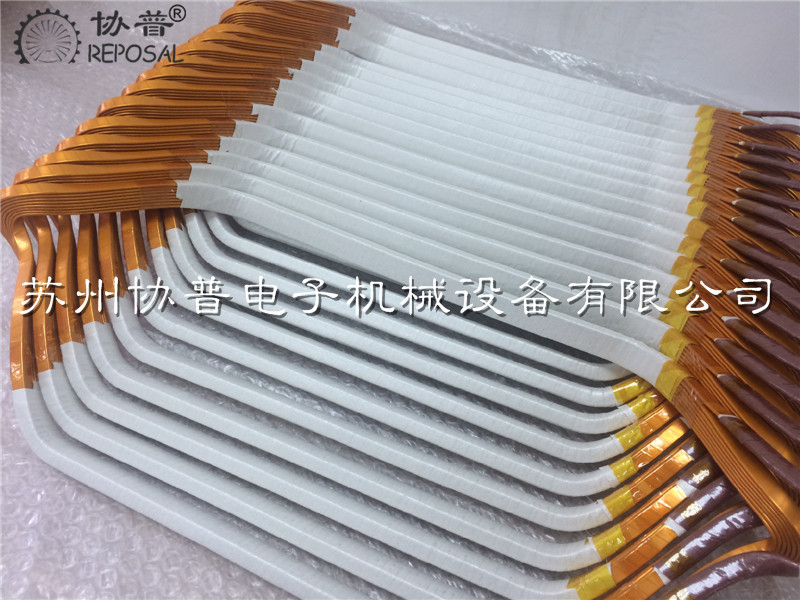

In recent years, due to self-adhesive support, self-adhesive coils do not need to be dipped in the later stage, which is convenient for industrialization. They have been widely used in deflection coils of precision instruments, combined coils in micro motors, and micro coils in sensors.

Self-adhesive enameled wire has become the main wire type used in the coil winding process due to its excellent heat resistance, insulation, adhesion durability, easy forming, simple winding process and other advantages. After the self-adhesive coil is formed, it is required that the DC resistance of the coil is good, the inductance performance is stable, the wiring is neat and not scattered, the surface is smooth and there is no gap, and the appearance is beautiful.

In addition, the coil needs to maintain a certain shape during use, which requires that the bonding strength of the coil does not decrease over time under different environments. In the winding process, especially for enameled wires below 0.1mm, there are often scattered, overlapping, loose and other phenomena. The factors that affect the winding quality are mainly considered from the enameled wire, winding equipment and tooling:

1 The influence of enameled wire on winding quality

The surface paint layer of the self-adhesive enameled wire is divided into two parts: a primer layer and a self-adhesive layer. The primer layer functions as an insulating layer and protects the internal copper core. The self-adhesive layer mainly plays the role of bonding and forming. The primer layer is formed mainly by dipping and baking, which is generally baked after two to three dipping. Both the primer and topcoat materials need to be filtered to filter gels and mechanical impurities. The solvent formula is reasonable, so that the wire coating can be cured smoothly without defects such as uneven thickness and bubbles. The uniformity, fluidity, and adhesion of the primer make the final film thickness uneven.

Take ELEKTRISOLA Ф0.06ABP15 self-adhesive wire as an example. The outer diameter is between Φ0.072mm and Φ0.075mm. According to actual experience, during winding, the wire spacing needs to be set higher than the diameter of the enameled wire. Enameled wire with a core material of Φ0.06 mm, and the spacing between the wires should be at least 0.08 mm. According to the bonding method, self-adhesive enameled wires are mainly divided into hot air, heating furnace, and alcohol bonding (soluble in absolute ethanol). Alcohol bonding is to directly bond self-adhesive enameled wires with industrial absolute ethanol (industrial alcohol, ethanol content is higher than 99%) when winding the coil. The limitation is mainly that alcohol has a swelling effect on self-adhesive materials, and there is excessive alcohol volatile concentration. High risk of spontaneous combustion or explosion, hot air or heating furnace method is convenient for mass production and automatic control. Therefore, the mainstream self-adhesive methods are mainly hot air, heating furnace and other heating methods. For thermal curing methods such as hot air and heating furnaces, the temperature of the heating process, the temperature gradient and the uniformity of the temperature have an important influence on the bonding performance of the winding. The bonding effect of self-adhesive enameled wire is mainly because the curing of self-adhesive paint is a staged polymerization process, at this time, the self-adhesive layer exists in the form of prepolymer. When the self-adhesive enameled wire is being wound, it needs to be heated (usually heated by hot air) to make it secondary polymerization and deep curing, so as to achieve the purpose of firm bonding.

When curing, you should refer to the manufacturer’s recommended curing temperature and curing time. If the temperature is too low or the curing time is insufficient, the curing reaction is insufficient, the polymerization reaction of the self-adhesive paint is insufficient, and the degree of crosslinking is low, which affects the intermolecular of the self-adhesive paint The force affects the bonding strength; when the temperature is too high, the self-adhesive paint is over-cured, the polymerization reaction has tended to end. If heating is continued, it will be difficult to carry out the crosslinking reaction on the one hand, and the original The cross-linking molecules are destroyed, reducing the bond strength. In the test process where the heating temperature is too high, the specific manifestation is that the sample is filmed and the adhesive force decreases. Therefore, controlling the curing process of self-adhesive paint is the key to the successful production of self-adhesive enameled wire.

In the actual winding process, the hot air temperature is related to the ambient temperature, and there is often a gap between the set temperature and the actual outlet temperature. A temperature sensor can be used to measure the air outlet temperature in real time to prevent the hot air temperature from being too high or too low. When selecting the self-adhesive enameled wire, it needs to be combined with the specific application environment. The key parameters include breakdown voltage, high and low voltage continuity, softening breakdown temperature, and re-softening temperature. Especially when it is applied to high temperature resistant devices, it is necessary to pay attention to the re-softening temperature. The re-softening temperature refers to the temperature at which the cured coil softens again. When this temperature is reached, the self-adhesive layer of the coil softens, the bonding strength decreases, and even the self-adhesive layer becomes viscous semi-solid, which affects the performance of the device.

Generally speaking, re-softening temperature <self-adhesive temperature.

Xiepu Electronic Machinery Equipment Co., Ltd. maintains a leading position in coil precision winding equipment. With the rise of the electronics industry, precision self-adhesive coil winding equipment has made great progress. Although the winding machine models are different, the most basic All are composed of control mechanism, tensioner and stepping mechanism.

1 Winding process flow Take the winding machine developed by Xiepu series as an example, the process flow of precision self-adhesive coil can be briefly described as:

(1) Pass the enameled wire through the tension mechanism of the winding machine in the correct way, and finally the wire clamping part clamps the end of the self-adhesive enameled wire.

(2) Adjust the tensioner to maintain the required tension.

(3) Through the control panel, call up the enameled wire winding program, which includes information such as winding turns, speed, feed, and initial position. Press the run button, the controller controls the movement of the cylinder to eject the winding shaft and fix the enameled wire on the winding shaft.

(4) The controller controls the rotation of the main shaft, winds the enameled wire, and controls the hot air at the same time

(5) After the winding is completed, the hot air device stops blowing hot air and stops heating.

(6) Take out the finished product and clamp the new product skeleton.

2 Movement analysis of the winding coil: Coil winding is the process of winding the enameled wire layer by layer on the skeleton or winding tooling through the tension control mechanism and the wire arrangement mechanism. For the coil with the skeleton, the enameled wire is wound on the skeleton. For sticking precision coils, enameled wire should be wound onto the tooling and hot air curing should be carried out at the same time.

Coil winding process: the enameled wire comes out of the raw material barrel, after passing through the tensioner, the wire maintains a constant tension, and then passes through the wire wheel of the wire arrangement mechanism. Before the coil is wound, the coil bobbin or winding tool is fixed on the main shaft. , The main shaft drives the coil to rotate, and the wire-arranging mechanism performs reciprocating linear motion at a speed matching the rotation of the main shaft, and the enameled wire is tightly wound on the skeleton or winding tooling. In the actual winding process, in order to achieve the ideal wiring effect, always keep the enameled wire directly above the skeleton, especially when the wiring mechanism changes direction, the wiring mechanism has no lead or lag relative to the winding mechanism, that is, set the winding Always keep the arranging mechanism and winding mechanism synchronized during the program parameters of the winding machine.

3 Control accuracy: the influence of the wire arrangement mechanism on the winding quality The position of the enameled copper wire is determined by the position of the wire arrangement, which is a mechanical device driven by a stepper motor to move the ball screw. The spindle motor is equipped with an encoder. From the analysis of the structure and the motion of the coil, it can be seen that the control accuracy of the automatic winding machine lies in how to express the relationship between the rotation speed of the winding spindle motor and the stepper motor input line length. At present, linear algorithms are generally used to describe the relationship between the two. However, in practical applications, the linear method will produce rounding errors, which makes this control relationship not only have poor control accuracy, but also have winding overlap or sparse winding problems. For example, if the speed of the spindle motor is constant, the speed of the stepping motor is higher than that of the main motor, and the winding spacing will increase; if the speed of the stepping motor is lower than the speed of the spindle motor, the enameled wire will accumulate. In addition, the commutation control of the winding mechanism has become a key factor in controlling the quality of the winding layer. The software can be used to control the matching of the speed and time of the stepper motor during commutation. Otherwise, it is easy to cause overlap or looseness between layers. The higher the machining accuracy of the winding spindle and the winding mechanism, the better. The mechanical part affects the winding accuracy of the lead screw.

4 The influence of the tensioner on the winding quality on the enameled wire, especially the fine enameled wire (the wire diameter rate increases. High-quality enameled coils require high precision for winding tension control, due to the small diameter of the enameled wire (Φ0.02~Φ0.lmm) , The allowable safety pull is small, the winding speed is high (above 3000 r/min), and the insulation layer is not allowed to have defects such as strain and paint damage[6]. In actual production, such as Φ0.04 mm wire diameter enameled wire, The control tension is 0.078±0.01N, and the wire diameter of enameled wire with Φ0.06 mm needs a tension of 0.137±0.039 N. There are many types of tensioners, and the precision can be roughly divided into servo type tensioners, electronic tensioners, and magnetic forces. /Magnetic tensioner, mechanical tensioner, the comparison is shown in Table 1. For winding small diameter coils, the first three types of winding machines are recommended.

5 The initial position affects the winding quality. The initial position of the coil is the first turn of the coil. The first turn is wound on the winding shaft. If the initial position is not close to the edge of the winding shaft of the coil, the first layer The coil will be uneven. As the number of turns increases during the winding process, the tightly packed coil will increase the unevenness of the winding, and finally the winding will appear scattered and uneven. For high-performance coils, when the coil is energized, the unevenness of the coil will increase the capacitance and inductance between layers and lines, which affects the use of the overall coil. For the automatic winding machine, the initial position is set by the program, and the consistency is good. For the winding machine that cannot be automatically wound, ensure that it is close to the edge of the winding shaft every time.

The article describes the evaluation method of the performance of the precision self-adhesive coil, the winding process and precautions, and explains how to improve the accuracy of the wiring mechanism and select the appropriate tensioner, winding tooling, fixed winding initial position parameters and self-adhesive enameled wire Can obtain better winding results.