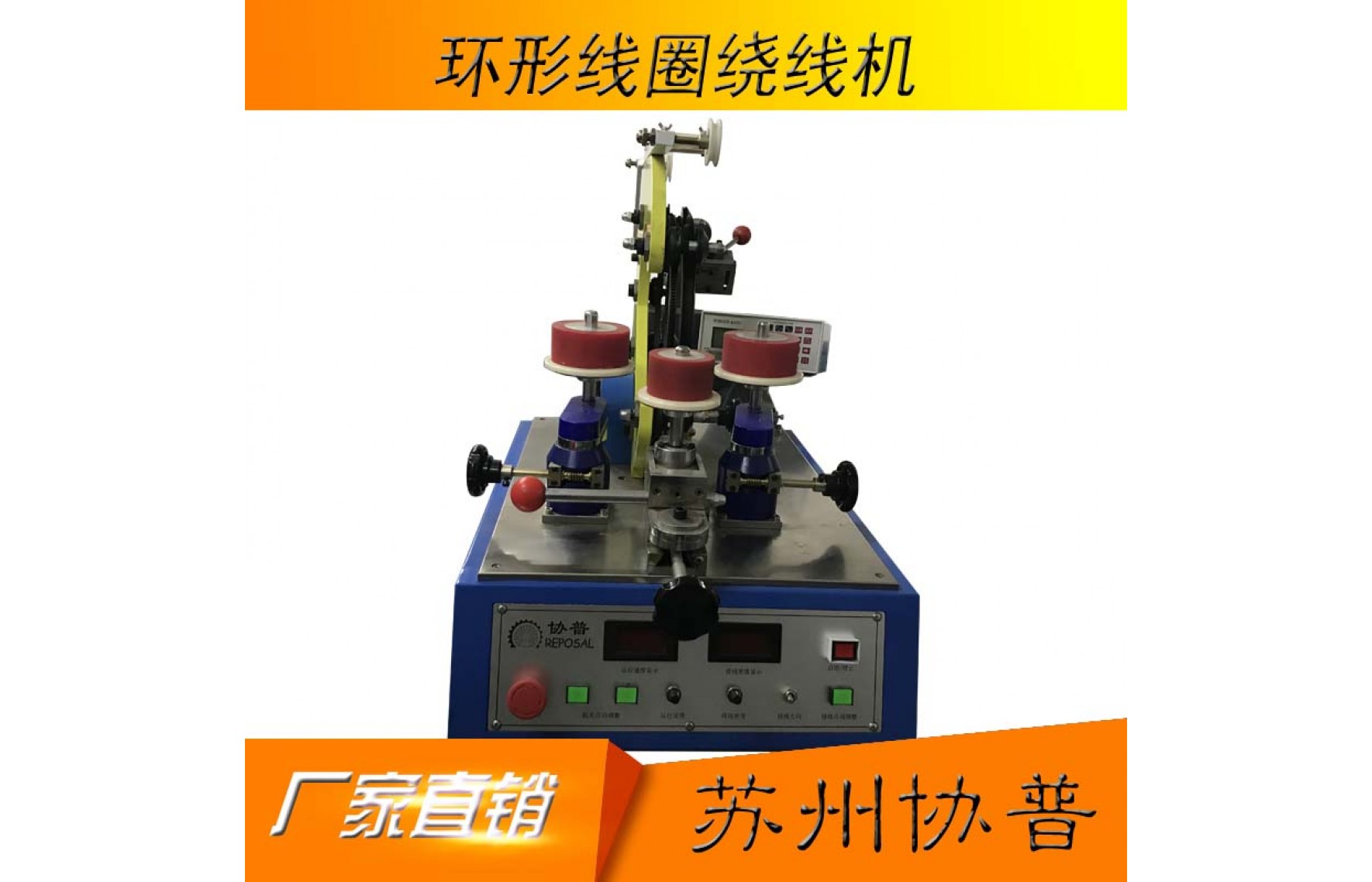

Video instructions for use of toroidal transformer winding machine

Suzhou REPOSAL Electronic Mechanical Equipment Co., Ltd. specializes in providing: toroidal transformer winding machine, current transformer winding machine, voltage transformer winding machine, ring voltage regulator winding machine, inductance coil winding machine, iron core chamfering machine , Parallel winding machine and other coil processing equipment and winding machine accessories.

The company has the advantages of R&D and production of the entire plant of electronic transformers and transformers. It is different from many assembly manufacturers in the industry. We have gathered many engineering and technical personnel in the winding machine industry. After many years of research and development and production experience, we have developed a new generation of series winding Equipment, especially toroidal winding equipment, is widely used in manufacturing industries such as toroidal transformers, transformers, voltage regulators, inductive coils, etc., and has received many praises from the industry; Customers provide more professional and quality products and services.

Technical characteristics of Xiepu toroidal transformer winding machine:

It adopts a microcomputer full Chinese LCD controller or CNC digital intelligent program controller, which is stable in operation and simple in operation, and has many advanced and practical functions pioneered by the industry.

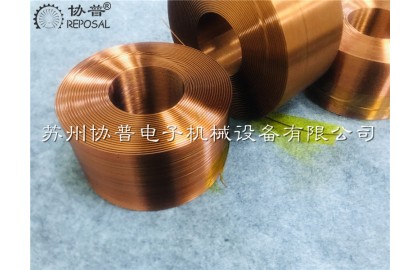

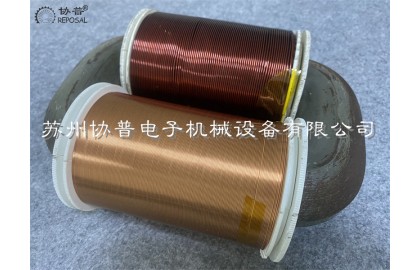

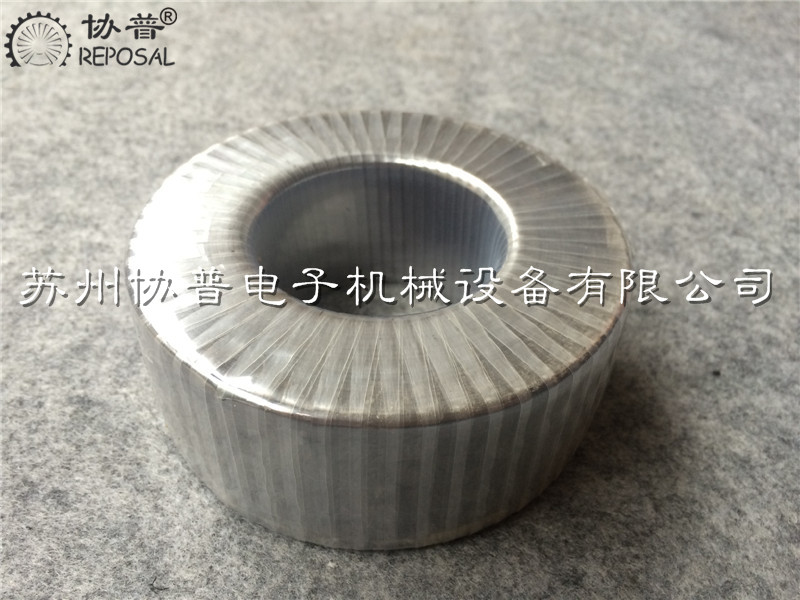

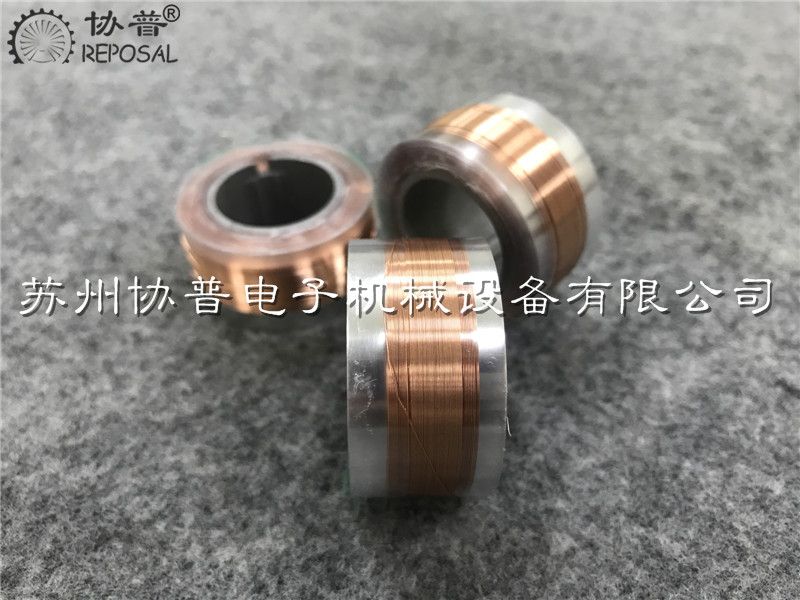

The core components such as wire storage ring and belt taker are made of high-quality steel through multiple processes, which are durable and not deformed.

Adopt the most advanced control circuit, with fault alarm function, function switches are two-wire control, maintenance and replacement is simple and convenient.

The running speed is set separately in the wire storage and winding state, which can automatically realize fast wire storage and low speed winding operation. The automatic operation function can also be used in the strapping machine mode. The operation is simple and the efficiency is high.

When processing multi-winding products, multiple wire storage and multiple winding procedures can be preset. It is suitable for products with multiple windings but different wire diameters/turns, or products with insufficient wire storage for a single time, avoiding repeated installation Clamp and manual operation to improve production efficiency.

Multiple sets of wire density can be preset. The device can automatically change the preset wire density when winding. When processing multiple winding products, each winding with different turns can be evenly arranged according to the preset angle.