Gear type ring coil wrapping tape machine

Gear type ring coil wrapping tape machine

Compared with the belt-type loop coil tape belt machine, the gear-type loop coil tape belt machine has a larger processing range and more storage capacity. Our company's gear-type loop coil belt tape machine can be coated with polyester film and polymer Imide, cloth tape, glass fiber tape, etc.

We now open the clamping seat of the gear-type ring coil tape belt machine, the storage ring opens, and then put the product on, the storage ring buckles, the clamping seat merges, and then pay attention to the insulating tape must pass through the middle of the scissors, etc. Cut it off with scissors at once, and then go in from any bearing above the storage ring from the outside to fix the tape head behind the storage ring. The first few laps are slow because they are in storage. Ok, the product is finished, now we take it off, and then close the storage ring, the clamping seat is restored.

Related Post

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

REPOSAL® releases layer-wound high-voltage package full-automatic interlayer insulation winding machine

Suzhou Xiepu Electronic Machinery Equipment Co., Ltd. successfully released the SP-D102M7 model of layer-wound high-voltage package automatic interlayer insulation winding machine-this model greatly improves the winding efficiency of layer-wound high-voltage package coils, and the coil is consistent Sex. The REPOSAL® winding machine reduces the winding cost of the layer-wound high-voltage package. In the new model, it has added a compact insulation belt automatic cutting mechanism, and high-quality solutions such as dynamic balance performance after multiple skeletons are wound.

Design and verification of winding machine for precision voltage transformer

In power transmission and power supply systems such as power plants and substations, voltage transformers are an indispensable electrical appliance. The voltage transformer for measurement specifies the accuracy level of the voltage transformer according to the error generated when the voltage is changed. Voltage transformers of level 0. 2 and above are generally called precision voltage transformers, which are mainly used in the laboratory to expand the measurement limit with the standard meter for precise measurement of voltage, power and electrical energy; or as a standard to check low standards, Low-accuracy voltage transformer; it can also be used with standard meters to test the corresponding meters.

With the rapid development of science and technology and electronic application technology, the requirements for technical indicators such as the rated primary voltage and accuracy of voltage transformers are getting higher and higher, and the demand for various types of voltage transformers is increasing. In the past, voltage transformers were mostly manually wound with annular iron cores and thick enameled wires. The products were large and heavy. In the daily winding, processing and production process, the degree of mechanization was not high, the labor intensity of workers was high, and the production efficiency was low. It is necessary to improve the voltage transformer design process and develop a new type of mechanical equipment for winding the voltage transformer.

Fiber Optic Gyro Winding Machine-REPOSAL® Winding Machine Official Website

Compared with mechanical gyroscopes, fiber optic gyroscopes have no moving parts, impact resistance, high sensitivity, and long life. Therefore, fiber optic gyroscopes are widely used in high-precision and high-speed positioning scenarios and will gradually replace electromechanical gyroscopes.

The basic components of the fiber optic gyroscope are the optical path and the circuit, and the fiber is the core component of the gyroscope. The fiber winding machine for preparing high-precision fiber coils has also become the key point of the gyroscope.

However, due to the blockade of its related technologies, the fiber optic gyro winding machine has always been a key technology insurmountable. REPOSAL® Electronic Machinery Co., Ltd. actively develops fiber optic gyro winding machines in response to market demand.

Through continuous research and improvement, we automate the winding process of the fiber optic gyroscope, and compare and analyze the winding methods of various fiber coils. We have obtained that the tension control and the accuracy of the winding during the fiber winding process affect the structure of the wound fiber coil. The key factor.

By optimizing the aforementioned tension control factors and winding accuracy algorithm, the effective and stable control of reasonable tension, the effective and reliable high-precision winding control, the memory of all process parameters, and the convenience of control, a new generation of optical fiber winding machine was developed and put into production .

With the practical application of research and development results, we will continue to improve and produce high-reliability and high-efficiency fiber optic gyro winding machines.

REPOSAL successfully developed string winding machine

REPOSAL takes the string winding machine as the research object and adopts the modal analysis method. Firstly, the vibration principle and the movement principle of the winding mechanism of the small string winding machine are discussed in theory. Based on the principle analysis, the vibration analysis of the ADAMS model of the small copper wire winding mechanism to study the vibration damping characteristics between the roller shaft and the frame is carried out respectively, and the wire winding mechanism of the string winding machine is made using ANSYS software. Modal analysis was carried out for normal operation. Through analysis, the vibration characteristics of the winding mechanism of the string winding machine under normal working conditions are obtained respectively to optimize the vibration damping measures of the winding mechanism. At the same time, the mechanical characteristics of the thin wire and CNC under the normal working state of the CNC winding mechanism are analyzed. , Optimizing the feasibility of applying the CNC cable winding mechanism to the string winding machine cable winding mechanism.

Ring wrap tape machine

Ring wrap tape machine

We will now demonstrate the operation of the loop coil strapping machine again, take the product, put it in, and then buckle this storage ring. Note that the insulating tape must pass between the two blades of the scissors After the fixed storage coil count is reached, the toroidal coil wrapping machine will rely on it to cut the insulating tape. Then, one end of the tape can be passed through any position of the bearing evenly distributed on the storage ring. After passing through, take the head of the insulating tape and hold it with the head, and then press and start with the right hand. The entire loop coil is covered with insulating tape It's done automatically.

Toroidal coil winding machine

Toroidal coil winding machine

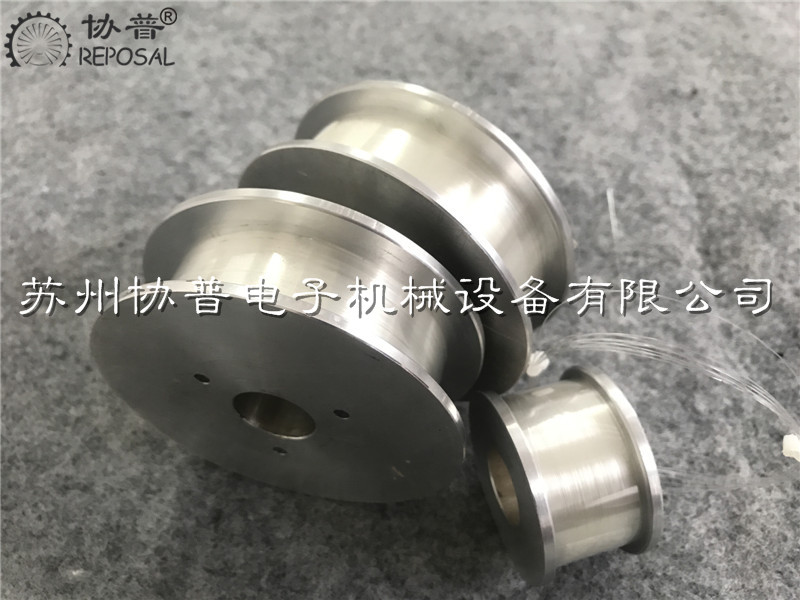

There are side-slip toroidal coil winding machines with processing coils, and belt-type toroidal coil winding machines with small-sized inductors.

Toroidal coil winding machines have the same specifications.Generally speaking, the smaller the inner diameter, the more difficult to process, and the thicker the wire diameter, the more difficult to process.

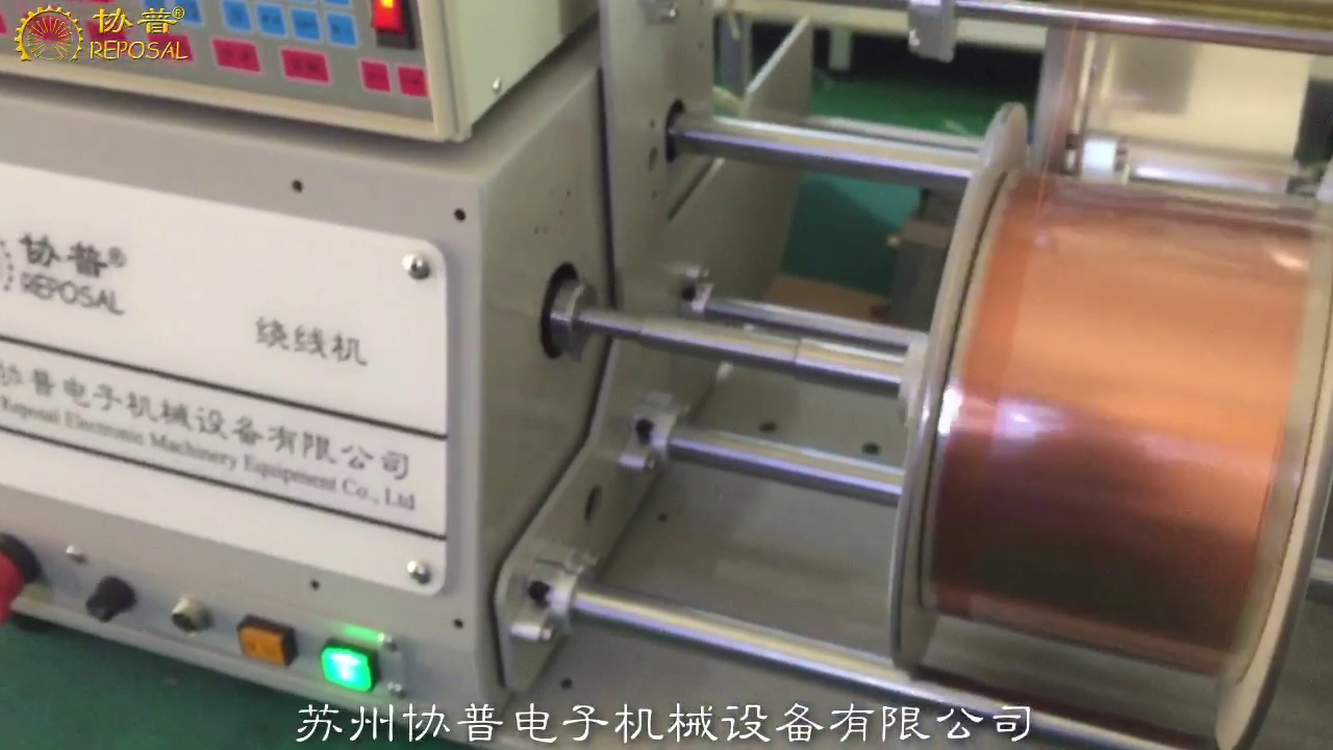

The video above shows the winding of an enameled wire with a diameter of 14mm and a diameter of 1.3mm.