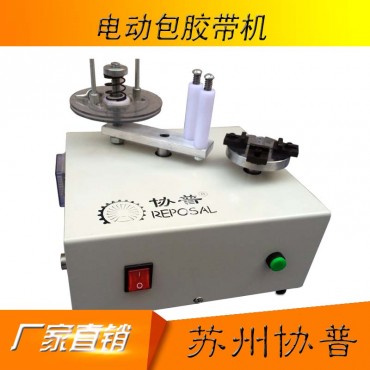

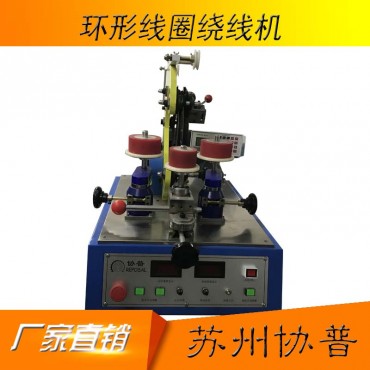

Transformer Insertion Machine

- Brand: 协普/REPOSAL

- Product Code: SP-EI78

- Availability: In Stock

- Ex Tax: login to see prices

Available Options

Transformer Insertion Machine

Transformer Insertion Machine (Operation video)

1. REPOSAL® manual inserting machine is mainly suitable for

low-frequency transformer silicon steel inserting, which has high efficiency

and good precision.

2. The overall use of high-quality steel, the processing accuracy is strictly controlled, the heat treatment process is in accordance with industry standards, the surface treatment is electroplated, wear-resistant and easy to use, low failure! long life!

3. The parts that must be frequently rubbed with silicon steel sheets, such as tongue pieces, are all imported from Japan. They are strictly in accordance with industrial standard processes, special treatment, less wear, low failure, easy operation, long life, and due to the control of processing accuracy To ensure the interchangeability of its parts.

4. Rotating the hand wheel adopts castings plus polishing and electroplating treatment, the hand wheel is smooth and smooth, and the shape is beautiful.

5. The structural accuracy of the transformer inserting machine can ensure the requirement of stacking thickness, so that the inserted silicon steel sheet is tight, eliminating the need for manual patching.

6. It can process silicon steel sheets with a thickness of 0.30 to 0.5 and second-hand neat annealed sheets and pin skeletons.

7. The processing efficiency of the inserter is not less than 120 groups / min (one E-piece plus one I-piece).

8. The current main models are: EI-28, EI-35, EI-41, EI-48, EI-57, EI-66, EI-76.2, EI-85.8, EI-96, EI-105, EI-114 , EI-133.2, EI-150

9. If the customer's product has special specifications or requirements, it can also be customized according to customer requirements.

1. Steps of using transformer inserter:

1. Check whether the initial model is consistent, and find that the uncoated coil needs to be picked out;

2. Check whether the position of the primary and secondary outlets is wrong;

3.Check whether the material specifications marked on the silicon steel sheet packaging conform to the technical requirements.

4. Put the silicon steel sheet of the corresponding specifications with the hairy side down into the card slot of the inserter, and then put the long wire of the qualified wire pack down into the inserter for inserting. Thickness needs to meet the requirements.

5. After inserting the film, place it according to the regulations to keep the next process normal;

6. Take the product and check whether the film is full, whether there are few cross-sections, etc .;

7.Place the product flat on the iron plate, take the E-type silicon steel sheet and add the I-piece at the same time with the burrs inward, and use the left hand to straighten it.Use an iron hammer to vertically fill the E-type silicon steel sheet and knock the iron core flat.

2. Matters needing attention in silicon steel sheet inserting machine:

1. When putting in the wire bag, the long end of the lead should be upward.

2.Master the strength and gestures when inserting the film, and do not insert the coil or lead.

3.The burr of silicon steel sheet needs to be consistent.

4.The silicon steel sheet must not have rust, deformation and other phenomena.

5.Do not skew and force the patch.

6.The rubber core cannot be repaired.

7.Pay attention to the cross when patching, less tablets and loose tightness.

8. During the operation, the silicon steel sheet needs to be handled gently.