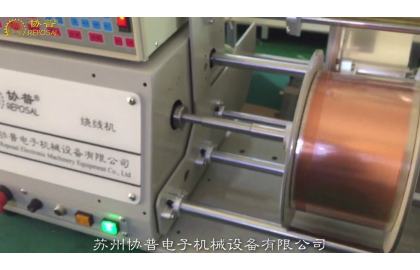

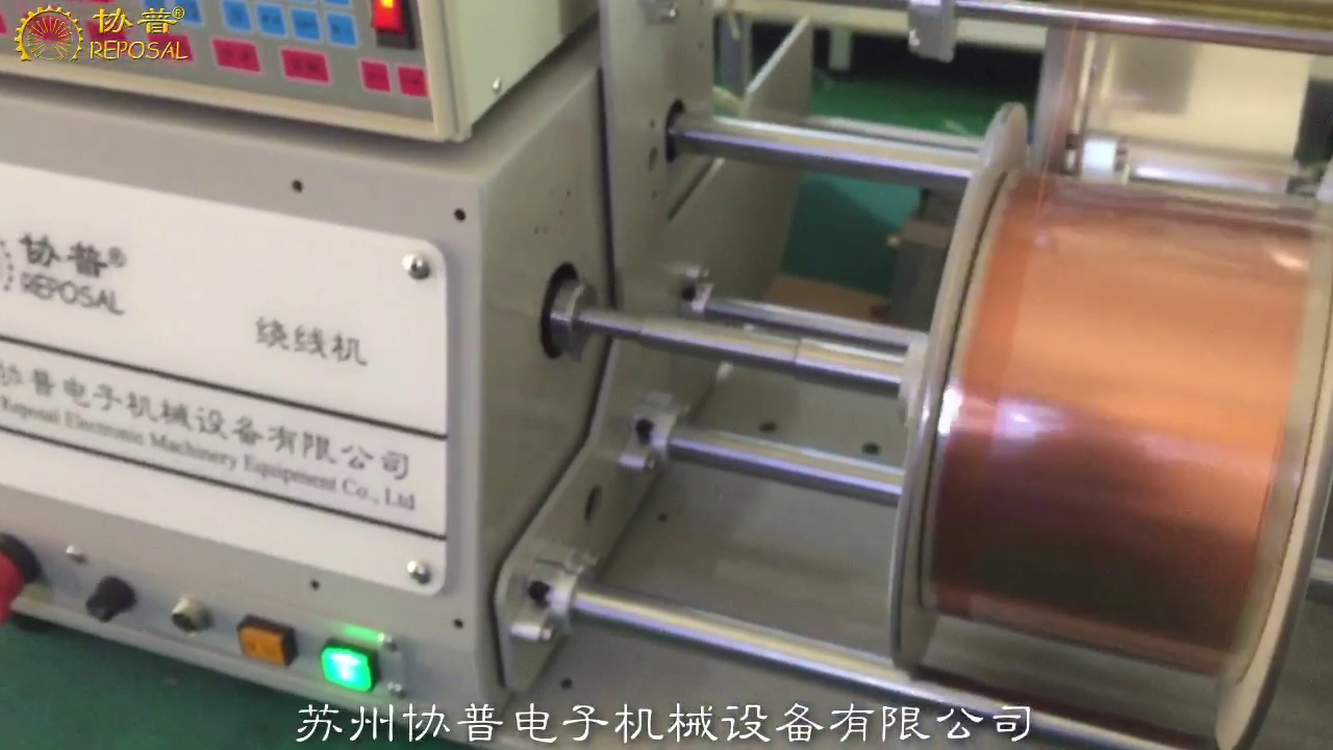

REPOSAL Winding Machine General Operation Manual

General Operation Manual for REPOSAL Winding Machines

Document No.: REPOSAL -CVC-FULL-C013Effective Date: October 20, 2015Version: V3.2

Scope of Application

This manual applies to CNC fully automatic and semi-automatic winding equipment, including standard winding machines for motor stators/rotors, transformers, inductor coils, etc., as well as special-purpose models such as single/double/four-station, flyer-type, and toroidal winding machines.

Safety Statement

The content of this manual complies with the basic requirements of the ISO 13849-1 functional safety standard. For the operation of specific models, it is mandatory to refer to the Special Instruction Manual provided with the equipment.

Operation of the equipment by unqualified personnel is strictly prohibited.

Document Revision Record

| Version | Revision Date | Overview of Revision Content | Reviser |

|---|---|---|---|

| V3.2 | 2015.10.20 | Integrated and optimized the content of V2.2, unified the format, and supplemented safety rules and maintenance details. | Technical Department |

| V2.2 | (Previous Version) | Established the general manual framework and clarified the scope of application and basic processes. | - |

Table of Contents

- Safety Instructions (Must Be Strictly Followed)

- Pre-Startup Preparation Work

- Detailed Explanation of the Operation Panel and Control Interface

- Parameter Setting Instructions

- Standard Operating Procedures

- Maintenance Plan

- Common Fault Diagnosis and Troubleshooting

- Supplementary Provisions

1. Safety Instructions (Must Be Strictly Followed)

⚠ WARNING: Failure to comply with safety regulations may result in severe personal injury, equipment damage, and property loss. All operators and maintenance personnel must receive comprehensive training and fully understand the content of this chapter.

1.1 Personnel Qualification Requirements

- Operators must complete systematic pre-job training, be familiar with the equipment structure, functions, and operating procedures, and can only take independent posts after passing the assessment.

- Unauthorized personnel and minors are strictly prohibited from operating the equipment. It is strictly prohibited to operate the equipment under the influence of alcohol, excessive fatigue, or drugs.

- Operators must wear standard work clothes, safety goggles, and anti-smash safety shoes during operation. Do not wear gloves, ties, necklaces, loose cuffs, or other items that may be caught by rotating components.

1.2 Operating Environment and Equipment Inspection

Environmental Requirements

The equipment shall be installed in a dry, well-ventilated workshop free of conductive dust. The ambient temperature shall be maintained at 15–35℃, and relative humidity at 40%–60% (no condensation). It should be kept away from strong electromagnetic interference, vibration sources, and corrosive gases.

Installation Requirements

- The equipment foundation must be stable and firm (levelness ≤0.2mm/m).

- A maintenance channel of ≥80cm shall be reserved around the equipment.

- Fire-fighting equipment shall be equipped nearby, and stacking of sundries is prohibited.