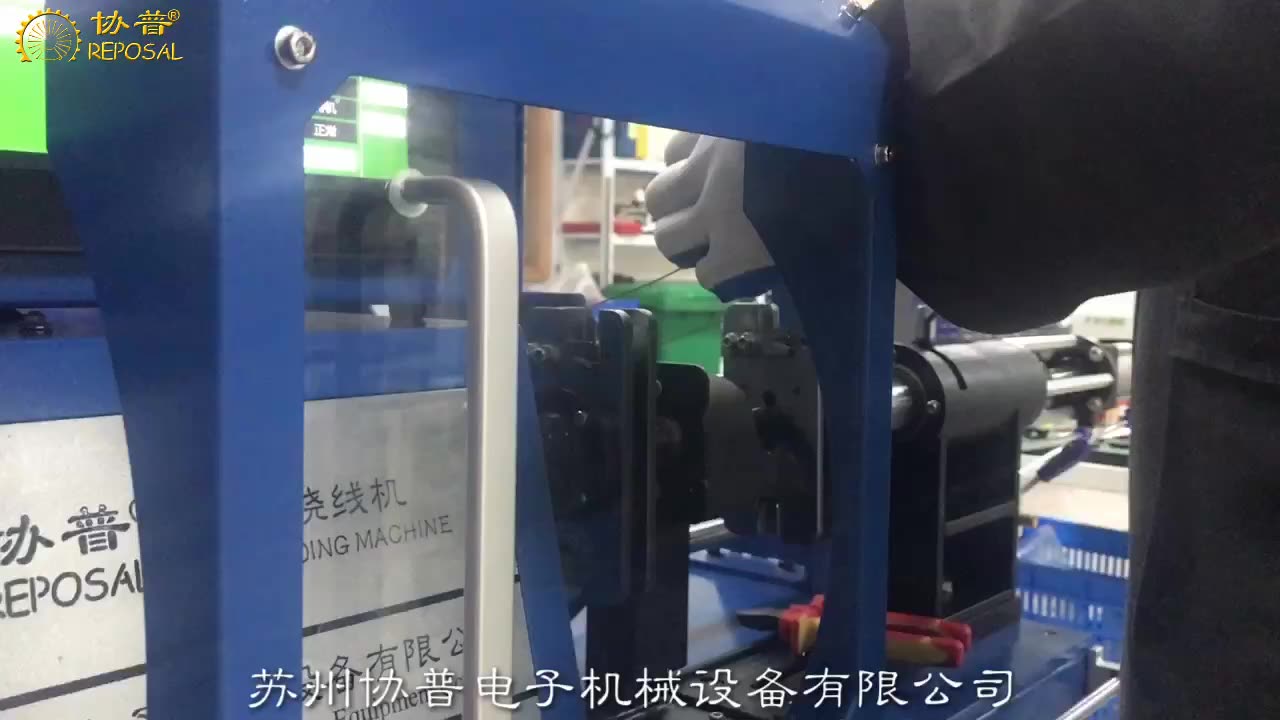

REPOSAL® precision winding machine

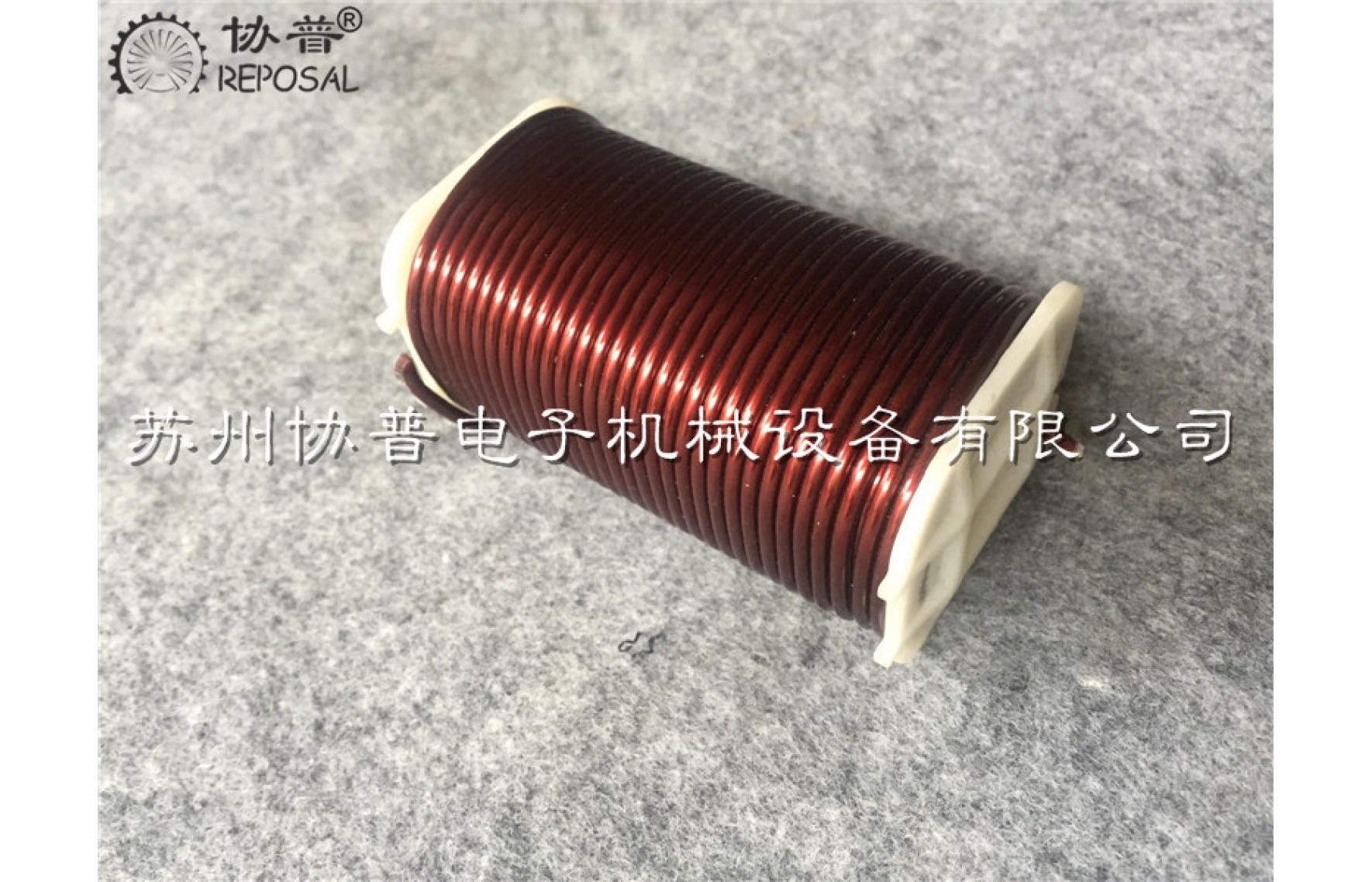

协普 / REPOSAL® winding machine has a strong technical accumulation in winding technology, taking the customized precision winding machine in the video as an example. The diameter of the enameled wire is 2.0mm, which requires the machine to be fast and stable, and the winding coils are arranged neatly, technology The indicators are highly consistent.

We also have different additional functions on the basis of this machine according to the specific requirements of customers, and derive other functions, such as a constant linear winding machine, the larger the diameter of the coil, the slower the corresponding speed For example, the automatic stripping function, some enameled wires are not wires that can be directly welded. With the automatic stripping function, when winding up, the beginning and end of the enameled wire have been stripped, which improves the processing efficiency and simplifies. The process route of the winding factory.

Related Post

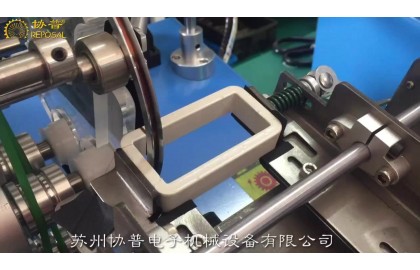

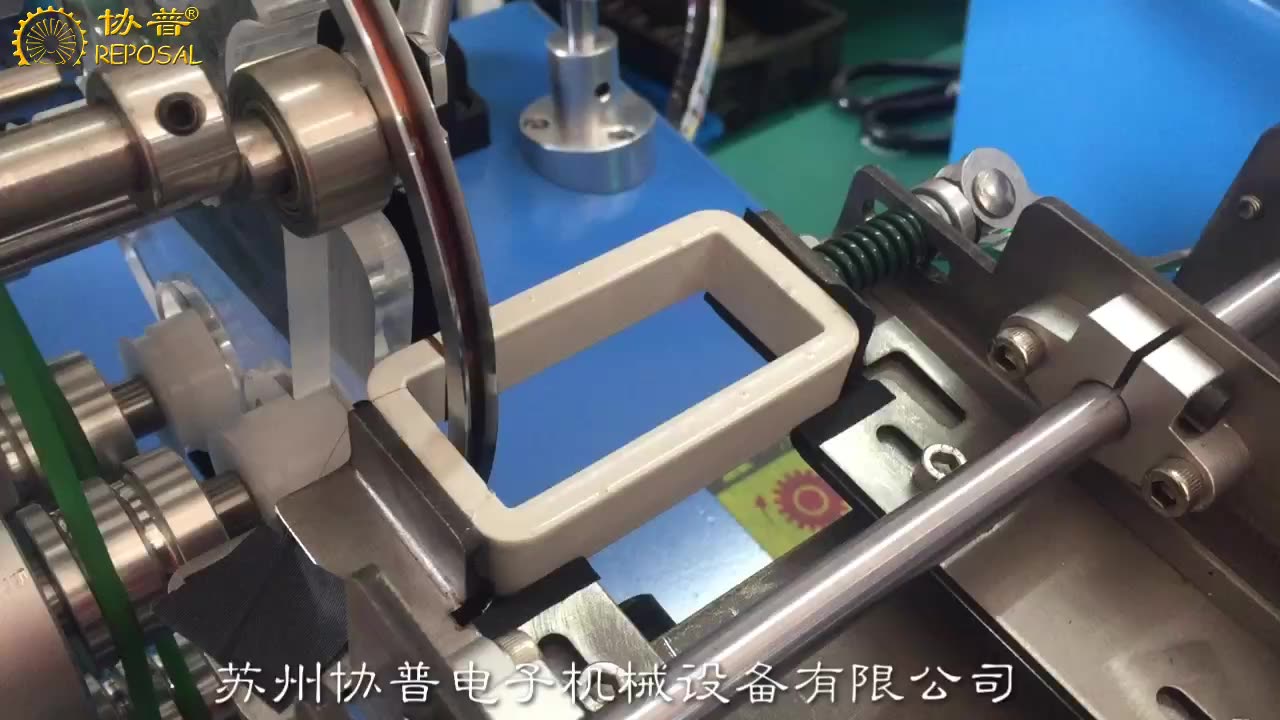

Enclosed rectangular transformer winding machine-thin wire reciprocating

Enclosed rectangular transformer coil with a thin diameter of 0.12mm, which requires fast winding speed and convenient product loading and unloading.

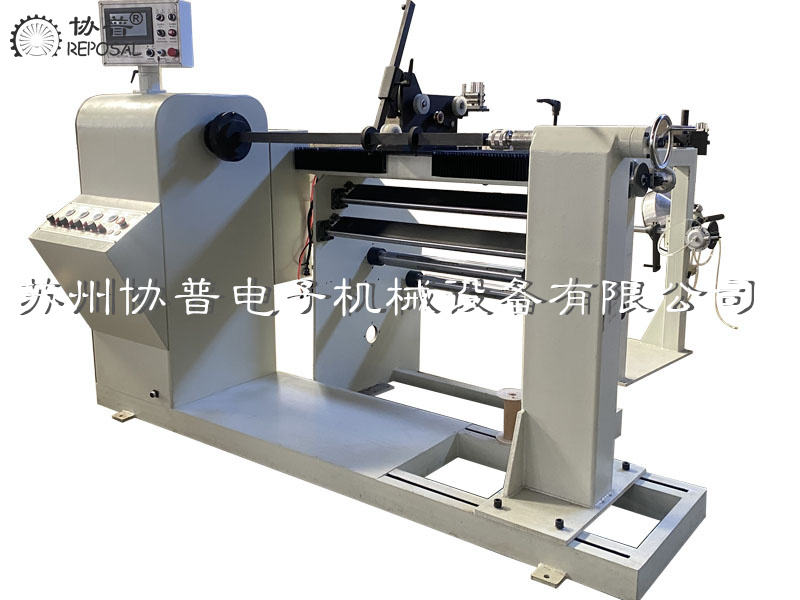

REPOSAL® Winding machine Optimum design of CNC winding machine for large power transformer

In the manufacture of power transformers, winding the transformer coil is a super important step, you think, the transformer coil is wound more firmly and neatly, the strength of the transformer and the ability to protect against short circuits can be greatly improved. However, most of the current transformer winding machines have to rely on manual extra sorting of the coil, the entire equipment is low in automation, and the production efficiency is not high, so the development of an excellent large transformer winding machine is a crucial thing for our company.

We have studied the main shaft technology of transformer winding machine, the relationship between compaction force and winding quality, and the control of compaction force. According to the principle and process flow of transformer winding, we put forward a whole design scheme of large transformer winding machine, including mechanical structure and electrical control. Mechanically, we simplify the complex structure of traditional transformer winders. In terms of electrical control, we ensure the stability of the motor when it starts and stops, and ensure that the winding coil is evenly tightened during the winding process. For the core parts of the transformer winding machine, spindle system and pressing device, we have calculated and selected the types and parameters. With the compaction device, we are able to provide real-time axial and radial compaction forces during the winding process of the transformer winding, which is very effective for improving the tightness of the winding.

The static analysis of the radial compaction device of the winding machine is also carried out by using finite element method, and the structure optimization is carried out according to the analysis results. We find that as the number of layers and turns of the winding increases, the required axial and radial compression forces change accordingly. By analyzing the experimental data, we find that there is a maximum value and a minimum value in the range of quality requirements, and it is the most reasonable choice to make the compression force approximately proportional to the number of layers and the number of turns.

The large transformer winding machine developed by our company has been preliminatively debugged and put into the market. After testing, the performance parameters of this transformer winding machine are in line with the design requirements, and the operation is stable and efficient. It can be wound to make a tight and regular transformer winding coil, and has been fully recognized by the market.

As a power grid equipment, power transformer converts voltage through the electromagnetic induction between the winding coils of the transformer. With the continuous development of the market, higher requirements are put forward for the manufacturing level of transformers, and the market needs more energy-saving and efficient transformers. Therefore, the optimization of the transformer manufacturing process is particularly critical. Quality and performance depend on the process equipment. The technical level of the transformer winding machine directly reflects the manufacturing level of the transformer. Therefore, accelerating the development of transformer winding machine is an important guarantee to improve the performance of transformer.

The winding coil of the transformer is the core component of the transformer and constitutes the electromagnetic induction part of the transformer. It generally includes high voltage winding and low voltage winding, respectively connected to the high voltage grid and low voltage grid. The winding of large power transformers usually adopts concentric winding, that is, the high and low voltage transformer winding coils are centrally set on the core column. The manufacture of transformer winding is the core process of transformer, and its quality plays a crucial role in the performance of transformer, affecting the appearance of transformer size, weight, mechanical properties, insulation and heat resistance and other important indicators.

In the past, the production of transformer winding coils relied on manual, and workers had to wind insulated wires manually to the winding die frame in accordance with the process requirements. Turns calculation also have to rely on manual, this old-fashioned method is inefficient, and because the worker's skills are not strong enough, the quality of the winding coil is poor, the number of turns may be miscalculated or missed, and ultimately lead to the finished winding coil performance can not be guaranteed. Later appeared semi-automatic transformer winding machine, which is driven by the motor to rotate the spindle to wind the transformer winding coil, although it improves the production efficiency, but the wiring work still has to rely on manual, only suitable for flat winding transformer winding coil winding, and winding head winding, welding and other operations must still be completed manually, so the product quality is not stable.

Later, with the emergence of TTL logic gate circuits, in the mid-1970s, with the development of CMOS technology, various types of equipment program control a large number of applications of digital integrated circuits, Western countries and Japan and other industrial powers have emerged CNC winding mechanism manufacturing industry. These CNC transformer winding machines represent the advanced level of winding mechanism manufacturing technology, especially the winding equipment produced in Japan, Italy, the United States and Germany is the leading technology.

Now the transformer winding machine as the core parts of the transformer production equipment, the market demand is very large, and the transformer manufacturing enterprises at home and abroad attach great importance to the development and application of advanced technology of transformer winding machine. Domestic transformer winding machine production enterprises are small, insufficient technical reserves, limited research and development funds, so there is still a big gap compared with foreign advanced products, the market share is low, unable to compete with foreign countries. To solve the key technical problems of transformer winding machine is the key to improve the quality of domestic winding equipment and enhance the market competitiveness. In order to meet the demand of transformer manufacturers for high quality and low price winding equipment, especially large transformer winding machine, on the basis of learning from foreign advanced experience, combined with domestic research results, the development of large transformer winding machine has important significance and practical value.

REPOSAL® has successfully released a radiofrequency ablation catheter winding machine

Radiofrequency ablation has ablation and cutting functions, and the main therapeutic mechanism is thermal effect. Radio frequency refers to radio frequency, frequency up to 150,000 times per second of high frequency vibration, but it does not belong to the division of bands in radio communication.

The coiling process is completed by continuous test and optimization of the coiling machine.

The working flow of this winding machine is as follows:

1. The active wire feeding device of the radiofrequency ablation catheter winding machine ensures that the wires are constantly connected and not tied.

2. Double fold section A measurement line.

3. Manual folding head.

4. Manually fix the thread head (Two schemes are tentatively proposed for fixing the thread head)

4.1 Fix the starting position with glue. The fixture locks the PEEK tube.

4.2 Kangtong wire is hung on the feature of steel pipe. Glue to fix the ends after wrapping.)

5. Press the start button of the radiofrequency ablation catheter winding machine to wrap.

6.(During the winding process of the radiofrequency ablation catheter winding machine, both AB and AB segments have adjustable tension)

7. Wrap the jump grid to the specified position (the specific hop length can be set, and the rotation Angle can be set.

8. After the radiofrequency ablation catheter winding machine is finished, the feeder stops at the end and maintains tension.

9. Fix the end of the line by manual dispensing

10. Both ends of the radiofrequency ablation catheter winding machine are coaxial, and the rotation direction is synchronized.

11. Adjustable pre-drawing force is required at both ends of the locking shaft core.

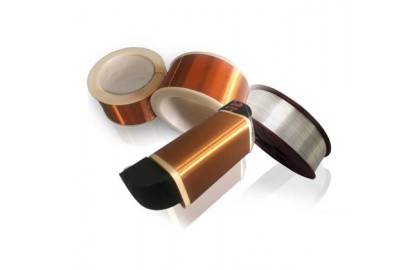

Transformer winding crepe paper | Transformer winding crepe paper | Transformer winding crepe paper

Transformer insulating crepe paper has good mechanical strength, high withstand voltage strength, wrinkles on the surface, and a certain degree of toughness. Moreover, it is easy to cut. After the transformer is wound and formed, it still maintains a certain strength in the oil immersion of the rear tooling. This feature can very well protect the enameled wire of the transformer from being squeezed and broken, that is, it meets the insulation requirements. It also meets the mechanical performance requirements.

Therefore, it is widely used for transformer insulation. Generally used in transformers, but less used in transformers, because the core structure of transformers is annular, because the surface of the insulating crepe paper has wrinkles and friction is large, so the annular wrapping machine is used. Winding is more difficult, so in general, if crepe paper is required for the transformer coil, manual winding is used. We have successfully overcome this problem by improving the details.

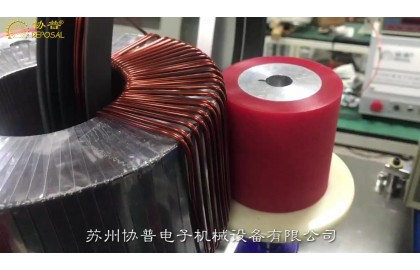

Common mode inductor winding machine 2

The function of common mode inductor is to suppress common mode interference, and it is a relatively important filter inductor.

It is different from a differential mode inductor. Although the two types of inductors are filter inductors, the different functions determine the appearance and winding method will be different. For the common mode inductor, it is wound on the same core, and the two The coil diameter of each winding is the same as the number of turns, but the winding direction is opposite. A set of coils has two pins, so the common mode inductor has 4 pins; while the differential mode inductor is wound on a core and only has A coil, so it has only 2 pins, so the common mode inductance and the differential mode inductance can be distinguished from the number of pins.

Also because the common mode inductor is two windings with opposite winding directions, the ideal winding effect is that the arrangement of the positive and negative directions is neat.

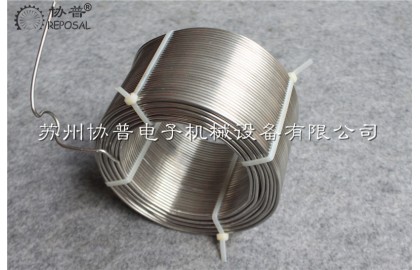

REPOSAL® releases double-wound thick wire diameter air core coil winding machine

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

Suzhou REPOSAL® Electronic Machinery Equipment Co., Ltd. released the sp-s112hb double-wound thick-wire air-core coil winding machine model-this model is mainly for the air-core coil with a large enameled wire diameter, and the winding speed is fast and consistent. Good performance, through the optimization of the control system and machinery, during the winding process of the larger enameled wire diameter air-core coil, it provides customers with a competitive solution for wire end fixation, tension control, winding accuracy, and demolding speed.

REPOSAL Winding Machine® Released high-speed precision synchronous winding machine

Suzhou REPOSA Electronic Machinery Equipment Co., Ltd. releases high-speed precision synchronous winding machine

Classification and difference of transformer winding machine

Classification and differences of common transformer winding machines

Choosing the right winding machine is the key to the production of coils. There are many types of winding machines as the basic equipment. This article mainly takes transformer winding machines as an example, and talks about its classification and differences, generally according to the voltage level or capacity of the transformer. Division, the common ones are ordinary CNC winding machines, automatic winding machines, foil winding machines, and vertical winding machines, etc.

Toroidal transformer winding machine

Toroidal transformer winding machine

The company has the advantages of R&D and production of electronic transformers and transformers in the whole factory equipment. Different from many assembly manufacturers in the industry, we have accumulated many years of experience in R&D and production in the winding machine industry and developed a new generation of toroidal coil series winding The equipment is widely used in the manufacturing industries of toroidal transformers, transformers, voltage regulators, inductance coils, etc., and has been well received by the industry; Suzhou REPOSL will continue to understand user needs and strengthen technical research and development and after-sales service levels, and provide customers with more professional and high-quality products and service.

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Technical features of our toroidal transformer winding machine:

Using CNC digital intelligent program controller, stable work, simple operation, with a number of industry-first advanced and practical functions.

The core components such as the thread storage ring and the thread belt are made of high-quality steel through multiple processes, which are durable and not deformed.

It adopts advanced control circuit and has fault alarm function. The function switches are all controlled by two lines, which is easy to maintain and replace.

The operating speed is set separately in the storage and winding state, which can automatically realize the fast storage and low-speed winding operation. The automatic operation function can also be used in the taping machine mode. The operation is simple and the use efficiency is high.

When processing multi-winding products, multiple storage and multiple winding procedures can be preset, which is suitable for products with multiple windings but different wire diameters/numbers of turns, or products with insufficient wire storage in a single time, eliminating repeated installation Clamping and manual operation improve production efficiency.

Multiple sets of wire density can be preset, and the device can automatically change the preset wire density when winding. When processing multi-winding products, each winding with different turns can be evenly arranged at a preset angle.

Double frequency conversion proportional drive, automatic operation or pedal speed regulation can be selected.

The speed can be adjusted steplessly, and the appropriate winding speed can be set according to the process requirements of different products.

Features:

The gear winding machine has the characteristics of large winding torque, high opening size of the gear ring roof ring, a large amount of wire storage and a large range of suitable winding diameters. It is the most versatile

Winding model; suitable for products with thick winding diameters, neat wiring requirements and multiple parallel windings, such as small toroidal transformer secondary windings, high-power 驽

Outer diameter: 193mm

Inner diameter: 95mm

Height: 90mm

Enameled wire diameter: 2.5mmX370

Influence of low enameled stress on formability in the process of winding enameled wire by winding machine

1 The formability of the enameled wire The mechanical properties of the enameled wire are divided into the mechanical properties of the conductor and the paint film. In the process of winding the enameled wire, in the wire embedding process, and in the electrical products using the enameled wire coil as a component, mechanical stress acts on the enameled wire during operation, so the enameled wire may be elongated and the paint film is damaged. etc. phenomenon. Therefore, enameled wire has the requirements of elongation, rebound angle, softness, tensile strength, paint film elasticity, paint film adhesion and scratch resistance.

1.1 Mechanical properties of conductors: softness, elongation, rebound angle, and tensile strength.

Elongation reflects the plastic deformation of the material and is used to assess the ductility of enameled wires. The springback angle and softness reflect the elastic deformation of the material and are used to evaluate the softness of the enameled wire. The tensile strength is related to the recovery recrystallization degree of the conductor and the grain size of the recovered tissue. The tensile strength, softness and elongation reflect the quality of the copper material and the degree of enameled annealing, which have a great impact on the quality of the winding. great relationship.

In the process of enameled wire coating, if the number of paint passes and the number of loops is too large, and the diameter of the guide wheel is not large enough, the wire will be continuously deformed by alternating tension and compression, resulting in the distortion of the lattice. It breaks easily when stretched. When the enameled wire is running, the wire is subjected to excessive tension, which will make the wire thinner. At this time, due to the displacement of atoms or ions on the lattice due to sliding, residual internal stress has been formed, so the wire is brittle and elongated. rate and softness rate decreased.

High-speed transformer winding machine

High-speed transformer winding machine

REPOSAL®winding machine's advantages in crossover winding machines

REPOSAL has invested a lot of R&D efforts in the field of crossover coil winding machines and has achieved a series of remarkable results.

In terms of winding accuracy, through in-depth research and optimization of the wiring mechanism and control system, REPOSAL's divider coil winding machine can control the winding accuracy within a very small error range. For example, for the wire with a thin wire diameter, the winding machine can accurately wind according to the set number of turns and arrangement, to ensure that the position accuracy of each turn of wire reaches ±0.05 mm, which greatly improves the quality and performance stability of the coil, and makes the crossover more accurate in the audio signal processing.

In terms of improving winding efficiency, REPOSAL has developed a unique high-speed winding technology. Thanks to the use of an advanced motor drive system and an efficient drive, the winding speed of the winding machine is increased by 30% compared to conventional models. At the same time, combined with the intelligent control system, continuous and uninterrupted winding can be realized, which greatly shortens the winding time of a single coil. For example, a common divider coil that used to take about 10 minutes to be wound by hand, but only 3 to 4 minutes with REPOSAL's winding machine significantly improved production efficiency and provided strong support for large-scale production.

In terms of versatility, REPOSAL's crossover coil winders are highly adaptable. By designing replaceable winding dies and flexible parameter adjustment functions, it is possible to wind a wide range of divider coils with different specifications, shapes and parameter requirements. Whether it's a crossover coil for a miniaturized audio device or a crossover coil for a large professional audio system, high-quality winding can be achieved on the same winding machine. For example, for coil skeletons with different inner diameters, outer diameters and height requirements, the winding machine can quickly switch production modes through simple mold change and parameter setting to meet diverse market needs.

In addition, REPOSAL also pays attention to the research on the convenience and intelligence of the winding machine. A concise and easy-to-understand human-computer interface has been developed, so that operators can master the operation method with only simple training. At the same time, the winding machine also has intelligent fault diagnosis and early warning function, which can monitor the parameters in the winding process in real time, and once there is an abnormal situation, such as wire breakage, abnormal winding tension, etc., it will immediately send out an alarm and prompt the cause of the failure, which is convenient for the operator to deal with in time and reduce the risk of production interruption and equipment damage.