环形绕线机绕线张力的分析

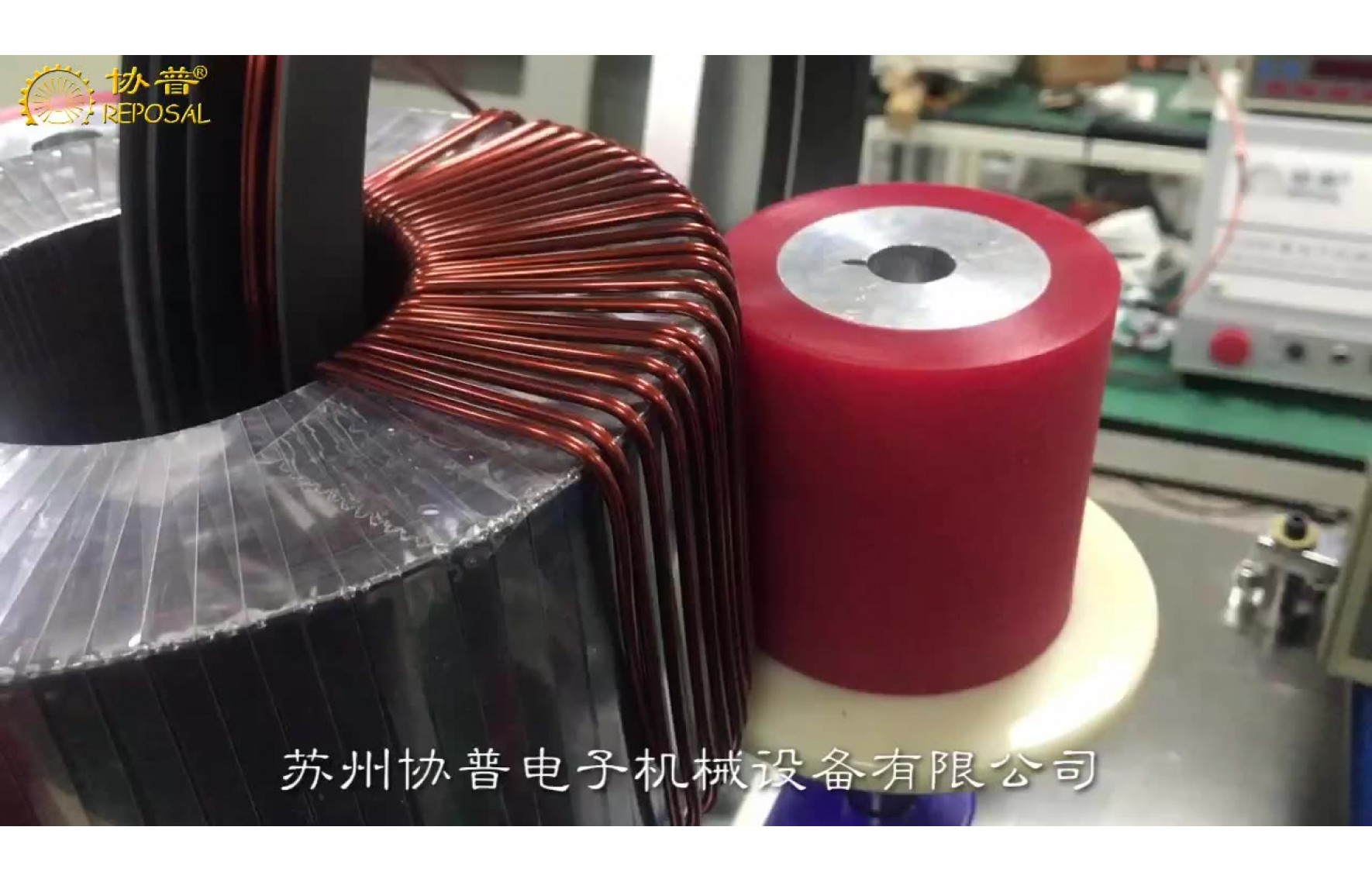

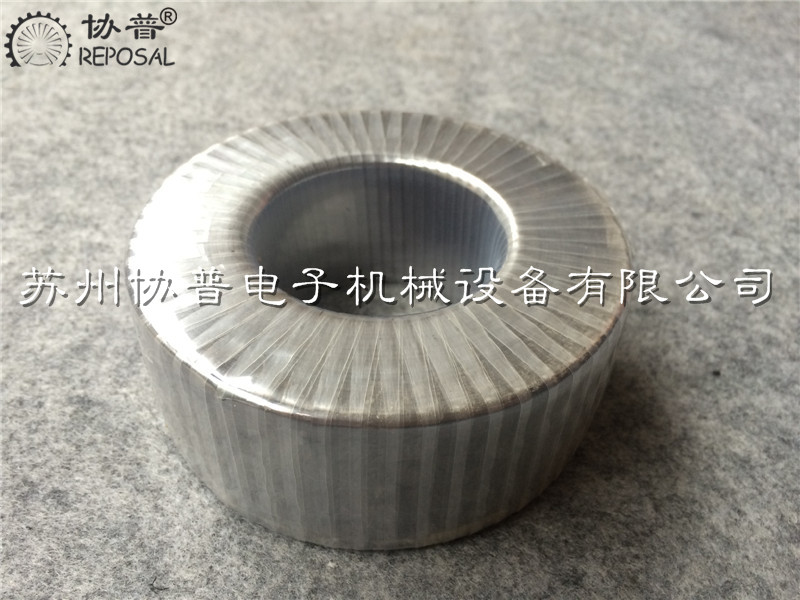

环形绕线机-环形线圈绕线机-在封闭的环形结构件上程辐射状的绕漆包线(具体参见环形绕线机使用教程):随着国内电力产业的迅猛发展,对电流互感器线圈需求量日益增大,开发电流互感器线圈绕制设备迫在眉睫为了满足市场的需求,我们在参考进口设备的基础上,开发出了电流互感器环形线圈绕线机,在设计,试验过程中,我们发现,环形绕线机的设计关键在绕线张力的控制。

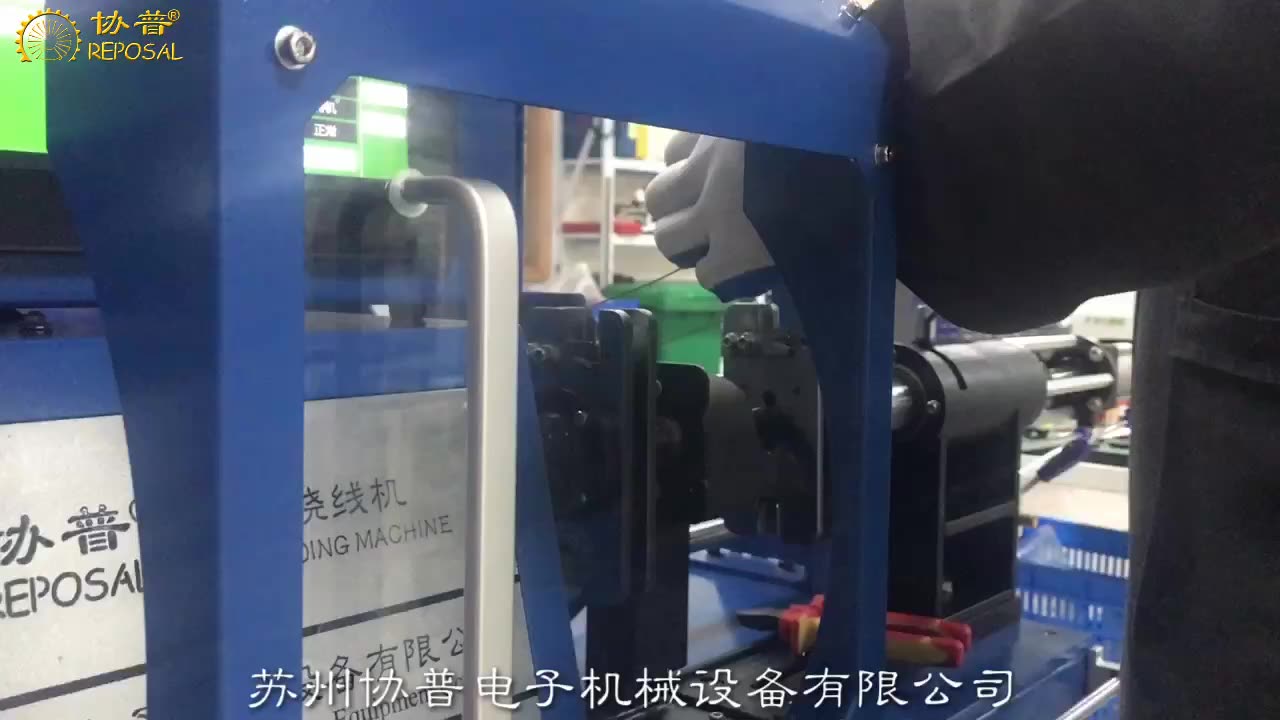

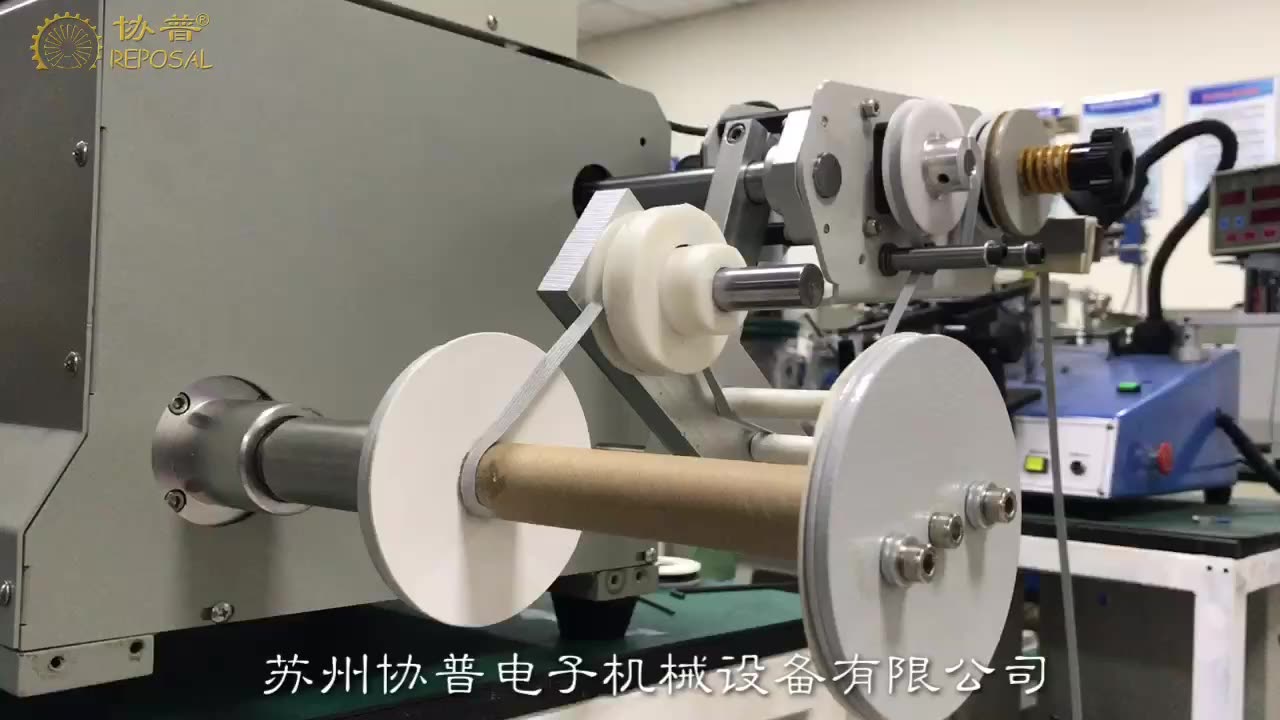

该款自动绕线机由机架、放线机构、绕线机头、包带机头、夹持装置、控制系统等组成。

环形绕线机,自动绕线机,

1、环形绕线机工作原理

先把导线均匀的缠绕在储线环上,然后再通过梭子把缠绕在储线环上的导线缠绕在骨架上,骨架由伺服电机带动旋转,使导线均匀地排列在骨架上线缠绕到一定量时,再把带通过储线环缠绕在骨架上,然后绕制。

2、绕线张力的分析

通过我们不断实践发现,在绕制整个过程中,用适当的力把导线拉紧缠绕在骨架上,是影响绕制好坏的关键所在,因此在下面我们着重说明影响绕线张力的因素。

1.线梭转动部分的磨察力矩

2.线梭部分(包括缠在线梭内的导线)加速度变化引起的惯性力矩。

摩擦力矩的主要部分是由张力机构产生的,它阻止线梭的放线运动而把导线拉紧,产生绕线张力。

由于绕线环形面及其在绕线齿轮中偏离中心位置的影响,即使是匀速绕线,线梭的运动速度也小是均匀的,这就产生了由加速度引起的惯性力矩,影响了绕线张力。

线梭的运动速度可看作由两种速度组成:一是与绕线齿轮上的滑轮速度相等的速度Vo,一是线梭放出导线的用量的速度,前者是常数,后者的计算如下(见图1)

3.环形绕线机绕线张力的分析1

所以为了减小线梭加速度,要求:

1.骨架型面H要小,型面尽量靠近绕线齿轮中心即1值小。

2.线梭平径R应尽量小。

3.绕线速度ω不能太高(这是与提高生产效率相抵触的)。

通过图解法得山线梭速度Vx与加速度а的近似曲线,说明如(见图2、图3):

4.环形绕线机绕线张力的分析2

1.当绕线齿轮上的小滑轮处于0°位置时,线梭的速度与小滑轮速度V0相等,当а从0-60°时线梭速度逐渐加快,此时有正的加速度当。=600-180`)范围时线梭等速运动,速度为Vm>Vo。当а=180°~263°时线梭速度逐渐减小,此时有负的加速度a = 263°线梭速度与滑轮速度V相等,当а=263°~345°时,线梭速度继续减小,即低于V并有负的加速度,当а=345°时,线梭速度为最小Vo,当а=345°~360°时,线梭速度逐渐上升即有正的加速度。

2.在绕线齿轮为匀速转动时,线梭速度小会为零,所以摩擦张力机构始终起制动作用,保持导线被拉紧。

3.若Vp为线梭平均线速度; Vo为绕线齿轮上的滑轮线速度;L为电位器一圈导线的俄周长,则

4.当绕线速度ω不大:线梭平径R较小,电位器型面尺寸H也较小,型面尽量靠近绕线齿轮中心时加速度的变化是小大的,由加速度引起的惯性力矩要小得多,所以影响绕线张力的主要因素是摩擦力矩。

我们在绕线机上使用凸轮控制摩擦张力,用以克服速度变化的影响,实践证明没什么效果,反而机构复杂制造调整都不方便,通过对张力的分析,设计时应考虑:

1.尽量减小绕线齿轮和线梭的直径。

2.线梭及其传动部件的转动惯量应尽量小。

3.张力机构产生的摩擦力矩要稳定。

4.机床的起动和转动应平稳。